Four Ways To Identify The Quality Of Aluminum Profiles

Aluminum profiles, as a common metal material, are widely used in construction, machinery, electronics and other fields. However, the quality of aluminum profiles on the market varies, here are four ways to identify the quality of aluminum profiles.

-

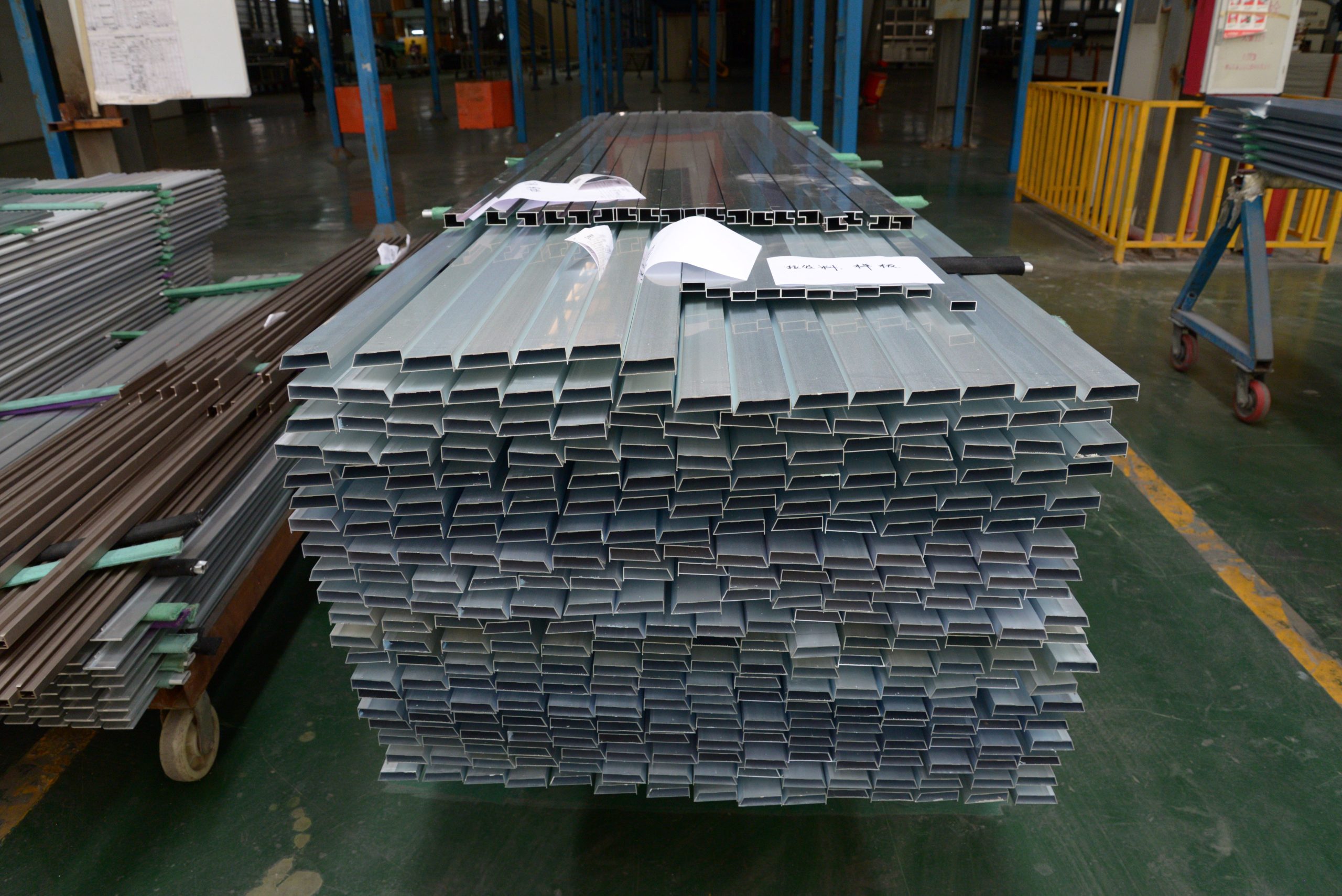

Appearance inspection

First of all, we can judge the quality of aluminum profiles initially through appearance inspection. The surface of high-quality aluminum profiles should be flat and smooth, without obvious scratches, depressions, bubbles and other defects. At the same time, the cross-section of the aluminum profile should be uniform, without obvious segregation, inclusions and other phenomena. If there are obvious defects on the surface of the aluminum profile or the cross-section is not uniform, then it is likely to be caused by improper production process or poor quality of raw materials, and consumers need to choose carefully according to the appearance needs.

-

Composition analysis

The quality of aluminum profile is also closely related to its composition. Generally speaking, high-quality aluminum profiles should use high-purity aluminum as raw material, and at the same time add appropriate amount of alloying elements to improve its mechanical properties and corrosion resistance. Therefore, we can judge the quality of aluminum profiles by analyzing their composition. If the aluminum profile has a low content of aluminum in its composition or too many impurity elements are added, its quality is likely to be affected.

-

Mechanical property test

In addition to appearance inspection and composition analysis, we can further judge the quality of aluminum profiles through mechanical property tests. Common mechanical property tests include tensile test, impact test, hardness test and so on. Through these tests, we can understand the tensile strength, yield strength, elongation, impact toughness and other performance indicators of aluminum profiles. If the mechanical performance index of the aluminum profile is low, then it may have problems such as fracture and deformation in practical application, and needs to be selected carefully.

-

Assessment of the production process

The production process of aluminum profiles also has an impact on their quality. High-quality aluminum profiles should be produced with advanced production processes and equipment to ensure that their dimensional accuracy, shape accuracy, surface quality, etc. meet the requirements. Therefore, we can assess the quality of aluminum profiles by understanding their production process and equipment. If the production process of aluminum profiles is outdated or the equipment is old, its quality may be affected to some extent.

In summary, judging the quality of aluminum profiles needs to be considered comprehensively from many aspects, including appearance inspection, composition analysis, mechanical property testing, and production process evaluation. Only by comprehensively understanding and evaluating all aspects of aluminum profiles can we choose high quality and reliable aluminum profile products to meet the needs of practical applications!

Hugh Aluminum is an aluminum extrusion manufacturer based in China. We manufacture aluminum profile products including aluminum railing, aluminum ceilings, aluminum decking, aluminum fence, aluminum doors and windows and aluminum roofings, solar aluminum frame . We offer large quantity of aluminum building materials and factory price.