Is the Extruded Aluminum Industry Profitable?

The aluminium extrusion industry is a money maker, driven by growing demand. As industries are looking for lighter, stronger materials, aluminium extrusions are the go-to for construction, automotive and renewable energy.

But while the profit is big, many factors affect the bottom line in this competitive market. Manufacturers have to navigate fluctuating raw material prices, labor costs, and logistics costs that can eat into profitability. Knowing these dynamics is key for businesses to succeed in the aluminium extrusion world.

Continuously Strong Demand for Aluminum Profiles

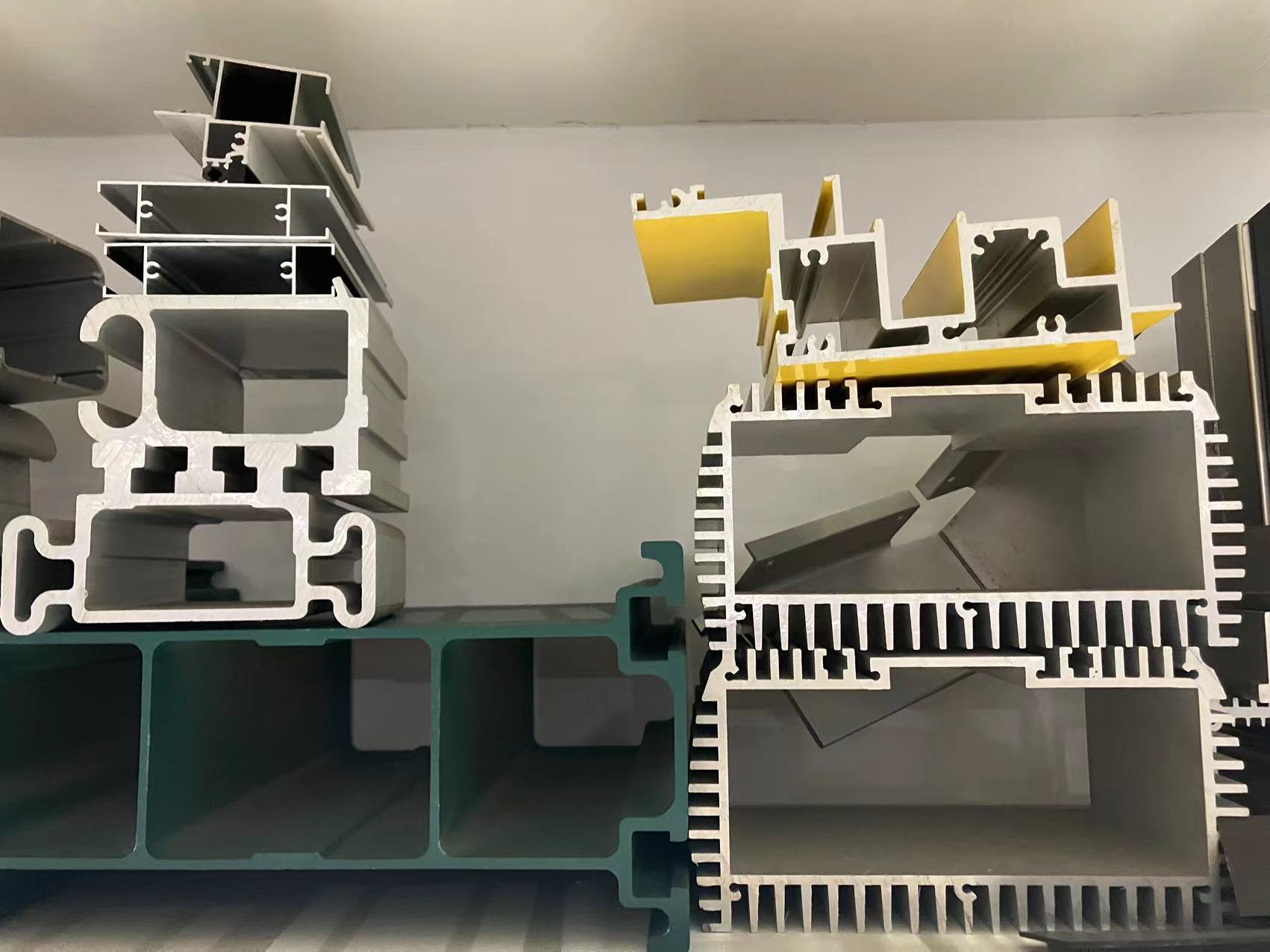

Aluminum and aluminum alloys are lightweight and easy to shape, leading to increased demand in various industries. There is significant potential for aluminum to replace other materials in many applications.

In construction, the phrase “saving wood with aluminum” reflects the trend of using aluminum alloy door frames and curtain walls. This shift has saved substantial wood resources. In transportation, aluminum is replacing steel in supporting structures for rail transit and high-speed rail systems, which boosts the demand for aluminum profiles.

Emerging fields also offer broad opportunities for aluminum profiles. The automotive industry is focusing on lightweight designs, especially with the rise of new energy vehicles. This trend has significantly increased the demand for aluminum alloys. Additionally, the new energy and consumer electronics sectors are rapidly adopting aluminum materials.

With strong demand across multiple industries, the aluminum extrusion market is well-positioned for continued growth and profitability.

Read more: The aluminum extrusions industry cost and profitability.

Challenges in the Aluminum Extrusion Industry

The aluminium extrusion industry has several big problems that affect its profitability and growth. These are low market concentration and high competition, limited funding for companies, and high entry barriers for new entrants. Knowing these is key to navigating the industry and finding success as outlined below.

Aluminum Extrusion Industry is Not Concentrated and Very Competitive

The aluminum extrusion industry includes many small and large companies, resulting in low market concentration. Most firms face limitations due to their size and service area. Consequently, many cannot compete with high-quality customer service and brand management. Additionally, these companies often do not invest in research and development or technology upgrades, which leads to a focus on low-end products.

In the low-end market, profit margins are thin, increasing the risk of price wars. Companies may lower prices to attract customers, which can further reduce profits. This competitive environment presents significant challenges for manufacturers aiming to maintain profitability in a crowded market.

Limited Financing Channels for Enterprises

The aluminum extrusion industry has high technical requirements and rapid equipment upgrades. Companies need to invest continuously in technological innovation and production line improvements. However, most firms in this sector are small to medium-sized, which limits their financial resources. As a result, many face widespread financing difficulties and high borrowing costs.

These financial challenges restrict investments in personnel training and technological research and development. Consequently, the growth potential for profitability in the aluminum extrusion industry remains low. Without access to adequate funding, companies struggle to enhance their operations and compete effectively in the market.

Entry Barriers

Aluminum extrusion products are highly customizable and serve various industries, including construction, rail transportation, photovoltaic equipment, and construction machinery. International buyers often conduct thorough evaluations before selecting suppliers. They assess technical capabilities, product precision, quality stability, supply capacity, and after-sales service.

As a result, switching suppliers can be costly. Once an aluminum extruder becomes part of a customer’s supply chain, they typically establish long-term relationships. This dynamic helps suppliers secure consistent profits. However, new entrants may face significant barriers to entering the market.

Final Thoughts

The aluminum extrusion industry has a small profit margin but maintains a stable profit cycle. It faces challenges such as low market concentration, intense competition, and limited financing options. However, increasing market demand and strong customer loyalty provide opportunities for profitability.

In the future, advancements in technology and lower manufacturing costs may further boost profits. Companies that invest in innovation and efficiency can position themselves for greater success in this evolving industry.