What is Extruded Aluminum Windows and Doors and How it is Made

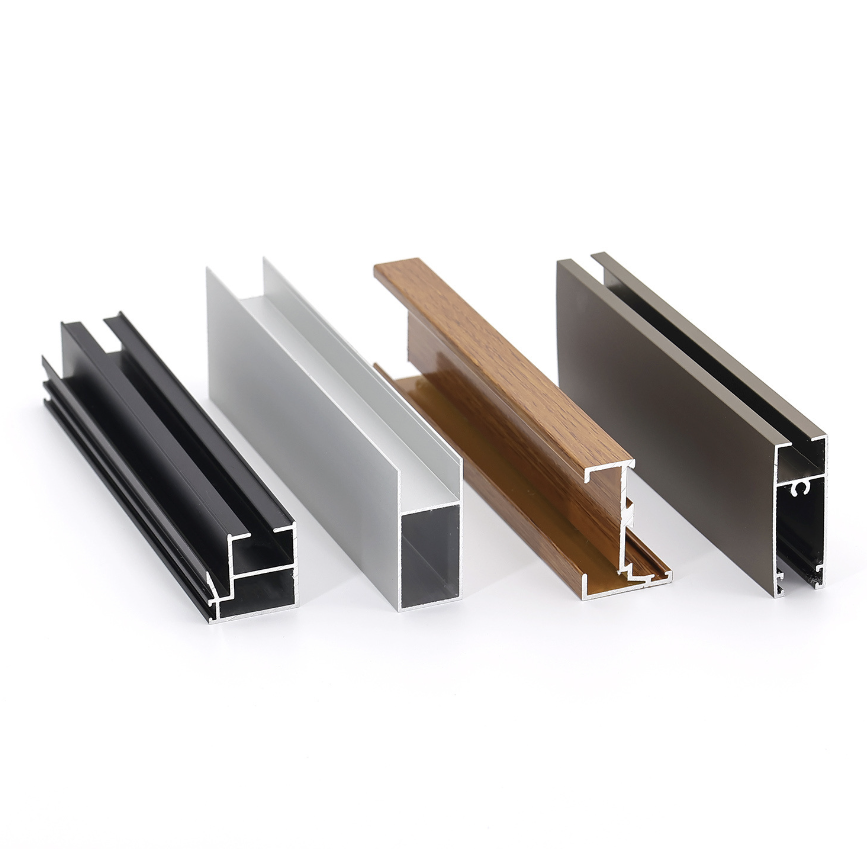

Extruded aluminum doors and windows are aluminum doors and windows produced by extrusion technology.

Brief introduction:

In the extrusion production process, the aluminum alloy material is extruded through high temperature and high pressure. It makes the window frame and sash become a whole, so as to achieve a better sealing effect.

This kind of doors and windows has excellent sealing, heat preservation and sound insulation properties, which is important for the quality improvement of modern buildings and energy saving and environmental protection.

Features of extruded aluminum doors and windows

1. Excellent heat preservation and sound insulation performance:

Due to the good sealing of extruded aluminum doors and windows, they can effectively prevent the transfer of indoor and outdoor heat and improve the thermal insulation performance of the building. At the same time, its good sound insulation performance can also reduce the interference of external noise, creating a quiet and comfortable living environment for the residents.

2. High strength and corrosion resistance:

The profiles of extruded aluminum doors and windows are mostly made of aluminum alloy material, which has high strength and corrosion resistance. Aluminum alloy materials can resist oxidation and corrosion, even in harsh environments can maintain the beauty and performance of doors and windows. In addition, aluminum alloy material also has high hardness and wear resistance, which can resist the impact and wear of external forces.

3. High precision:

The production process of extruded aluminum doors and windows can accurately form complex cross-sectional shapes and wall thicknesses under the control of the die, which greatly improves the precision of aluminum geometric dimensions. This precision makes the dimensions of the doors and windows more accurate and the installation more convenient and quick.

4. Environmental protection and energy saving:

Extruded aluminum doors and windows have good thermal insulation and sound insulation properties, which can effectively reduce the transfer of energy and noise interference, and improve the thermal insulation and sound insulation effect of the building. This environmentally friendly and energy-saving feature is in line with the concept of sustainable development in modern society.

How to manufacture extruded aluminum doors and windows:

1. Raw material making:

- According to the composition content ratio requirements of aluminum profiles, reasonably equipped with a variety of raw materials.

- Heat the aluminum ingot to a molten state and add an appropriate amount of alloying elements (such as magnesium, silicon, etc.).

- Remove the impurities and waste gas in the melt by means of refining.

- Under qualified casting process conditions, the molten aluminum liquid is poured into the casting machine, cooled and cast into round casting rods as expected.

Belows video from Hugh Aluminum shows aluminum extrusion:

2. Aluminum bar extrusion:

- Lay aluminum rods flat on a stock rack, maintaining proper spacing to prevent rolling or dropping.

- Heat the aluminum rods and dies in a furnace to a certain value (e.g. 480°C) and hold for a certain period of time (e.g. 1 hour).

- Install the die in the die holder of the extruder and place the aluminum bar into the inlet of the extruder.

- Pressure is exerted on the aluminum bar through the extruder so that it flows out of the die to form a profile.

- During the extrusion process, a haul-off machine draws the profile and makes the initial cut according to the set length.

- The profile is sent to the alignment table for straightness correction and then transported to the finished product area for cut to length.

3. Ageing treatment:

The cut aluminum profiles are loaded into the material frame and transported to the aging area. Heated to a certain temperature (e.g. 200℃) in the aging furnace, and held for a period of time (e.g. 2 hours). It can improve the mechanical properties of aluminum profiles, especially the hardness.

4. Subsequent processing:

According to the need, the aluminum profile is cut, punched, tapped and other subsequent processing for installation and assembly.

5. assembly:

Clean and degrease the parts before assembly and put them into the assembly box for spare. Then put the assembled frame at the mounting position to fix the position. Finally, use the bolts to fasten the connectors to complete the assembly work.

After completing these production steps, we can get a complete and beautiful aluminum doors and windows.

To summarize

Extruded aluminum doors and windows have excellent sealing, heat preservation, sound insulation and high strength. The production process of extruded aluminum doors and windows includes raw material production, aluminum bar extrusion, aging treatment and other steps, through the scientific production process and strict quality control to ensure that the quality and performance of doors and windows meet the standard requirements.

Hugh Aluminum is an aluminum extrusion manufacturer based in China. We manufacture aluminum profile products including aluminum roofings,aluminum heat sink, aluminum deck, aluminum fence, aluminum doors and windows, solar aluminum frame. We offer large quantity of aluminum building materials and factory price.