What is 5000 Series Aluminum

What is 5000 series aluminum:

5000 aluminum alloy is an aluminum alloy material that contains a variety of metallic elements. It has unique physical properties. Therefore it can be widely used in several industries. The following is a detailed introduction about it.

Its metal composition:

The main component of 5000 series aluminum profile is aluminum with a certain proportion of magnesium, and the magnesium content is usually between 3-5%. For example, the magnesium content of 5052 aluminum alloy is about 2.5%, while the magnesium content of 5083 aluminum alloy is as high as 4.0-4.9%.

5xxx aluminum series physical properties:

1. Strength:

- Tensile strength: 5000 series aluminum profiles have high tensile strength and can meet various occasions with high strength requirements.

- Fatigue strength: some grades such as 5052 aluminum alloy has good fatigue strength, suitable for occasions that need to withstand cyclic loads.

2. Corrosion resistance:

5000 series aluminum profiles perform well in corrosive environments such as seawater and chlorides, and have strong corrosion resistance. Especially when the magnesium content is within a certain range, its corrosion resistance is further enhanced.

3. Machinability:

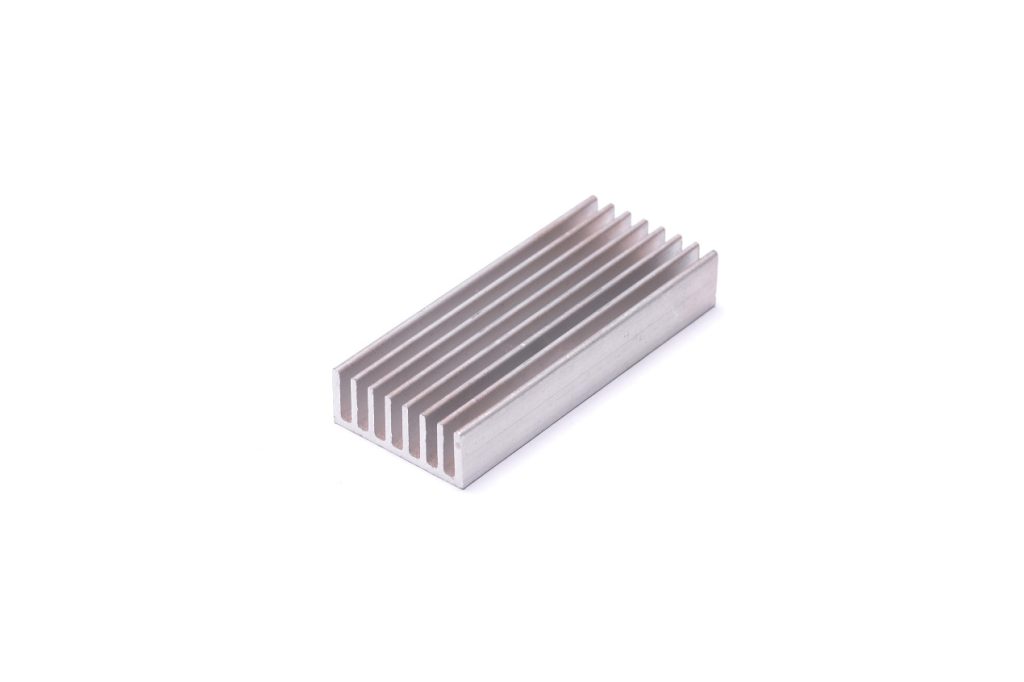

5000 aluminum profiles have good forming and processing performance, easy to process into various shapes and sizes, easy to fabricate in practical applications.

Certain grades such as 5052 aluminum alloy also has good machinability and can be cold worked to improve strength.

4. Weldability:

- 5000 series aluminum profiles have good weldability, which facilitates welding operations in practical applications. For example, 5083 and 5086 aluminum alloys have good weldability.

- Based on these physical properties, we understand that it is a high-strength, corrosion-resistant and aluminum alloy with excellent workability. So what industries can it be used in?

Grade 5083 Aluminum Alloy

- Strength: Among the 5000 series aluminum alloys, 5083 aluminum alloy has high tensile strength (σb ≥ 270MPa).

- Corrosion resistance: the alloy has excellent corrosion resistance, especially outstanding resistance to seawater corrosion.

- Machinability: 5083 aluminum alloy can be machined into parts of various shapes and specifications.

- Anodizing treatment: After anodizing treatment, the surface of 5083 aluminum alloy is beautiful, increasing its decorative and corrosion resistance.

- Welding performance: it has good arc welding performance and can perform conventional welding operations such as argon arc welding, MIG welding and TIG welding

The composition of 5083 aluminum alloy:

| elemental | Content range(%) |

|---|---|

| aluminum (Al) | Usually around 97.6% |

| silicon (Si) | ≤0.40% |

| copper (Cu) | ≤0.10% |

| magnesium(Mg) | 4.0~4.9% |

| zinc (Zn) | ≤0.25% |

| manganese (Mn) | 0.40~1.0% |

| titanium (Ti) | ≤0.15% |

| chrome (Cr) | 0.05~0.25% |

| iron (Fe) | 0.000~0.400% |

Grade 5754 aluminum alloy

5754 aluminum alloy is a common alloy belonging to the 5000 series. It has good corrosion resistance, strong toughness and plasticity, and can withstand large mechanical stresses. Grade aluminum 5754 has these characteristics:

Excellent corrosion resistance

5754 aluminum alloy has high resistance to corrosive mediums such as seawater and chlorides, so it is widely used in offshore engineering, oilfield equipment and other fields.

Medium Strength:

Aluminum alloy 5754 has medium strength and is capable of meeting the needs of a wide range of engineering applications.

High Strength Potential:

With proper heat treatment, 5754 aluminum alloy can achieve high strength, further enhancing its value in use.

Good toughness and plasticity:

Alloy 5754 is able to withstand large mechanical stresses and maintains good deformability during processing. Therefore it can be used as a material for submarine pipelines.

Chemical composition of Grade 5754

| elemental | Content range(%) |

|---|---|

| aluminum (Al) | around 96% |

| silicon (Si) | ≤0.40 |

| copper (Cu) | ≤0.10 |

| magnesium(Mg) | 2.6~3.6 |

| titanium (Ti) | ≤0.15 |

| Zinc (Zn) | ≤0.20 |

| manganese (Mn) | ≤0.50 |

| chrome (Cr) | ≤0.30 |

Grade 5251 aluminum

Grade 5251 aluminum is a common aluminum alloy in the 5000 series of aluminum alloys. It has a variety of excellent performance characteristics, such as good corrosion resistance, high strength, wear resistance and good welding performance.

It is very strong grade of aluminum alloy:

5251 aluminum alloy has good tensile strength and yield strength, which can meet the requirements for strength of various structural components.

Excellent corrosion resistance:

It has good stability in wet environments or under some chemical media, and is able to resist oxidation and the erosion of many corrosive media.

Chemical composition of Grade 5251:

| elements | Content range(%) |

|---|---|

| aluminum (Al) | around 97.5% |

| silicon (Si) | ≤0.40 |

| copper (Cu) | ≤0.10 |

| magnesium (Mg) | 3.5~4.5 |

| Zinc (Zn) | ≤0.25 |

| manganese (Mn) | 0.20~0.7 |

| titanium (Ti) | ≤0.15 |

| chrome (Cr) | 0.05~0.25 |

| iron (Fe) | 0.000~0.500 |

Applications of 5000 series aluminum products:

1. Aircraft Manufacturing:

Due to its light weight, high strength and corrosion resistance, 5000 series aluminum alloy has a wide range of applications in the field of aircraft manufacturing, such as for the manufacture of aircraft fuselage, wings and other components.

2. Spacecraft Manufacturing:

In the aerospace field, 5000 series aluminum alloys are also often used in the manufacture of rockets and space satellites and other components to meet the requirements of spacecraft for light weight, high strength and corrosion resistance.

3. automotive manufacturing:

In the field of automobile manufacturing, 5000 series aluminum alloys are widely used in the manufacture of body, engine, transmission system and other components to reduce the weight of the vehicle and improve its performance. For example, 5083 and 5052 aluminum alloys are commonly used in the manufacture of automobile body panels and parts.

4. Shipbuilding:

5000 series aluminum alloys are also widely used in the field of shipbuilding due to their good corrosion resistance, such as for the manufacture of hulls, decks and other components.

Finally, to summarize, through the discussion in this article. We have realized that 5000 series aluminum profile is an aluminum alloy material with high magnesium content. Its excellent physical properties enable it to play a major role in aerospace and aviation.

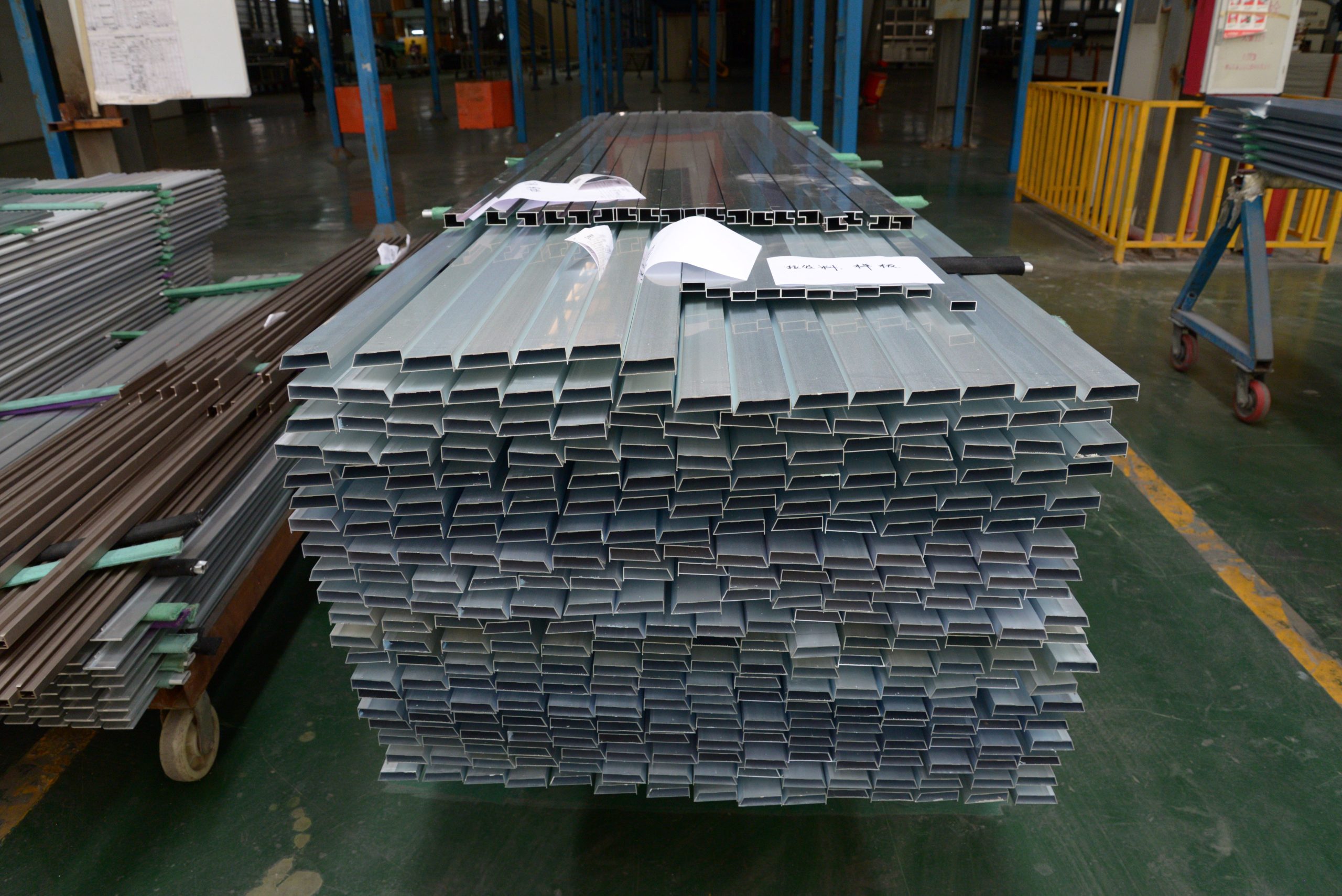

5000 series aluminum alloy extrusions are available here!

Hugh Aluminum is a large aluminum extrusion manufacturer, we are equipped to produce 5xxx-7xxx series aluminum alloy extrusions. If you want to purchase it in bulk? Please don’t hesitate to contact us!