What is Aluminum Extrusion Large Enclosure?

Aluminum extrusion large enclosures are created by shaping aluminum alloy into strong and precise structures. The process involves heating aluminum until it softens and then pushing it through a die to form a specific shape.

This method allows for the creation of large enclosures with accurate cross-sections and consistent lengths. It efficiently produces durable and versatile components for various applications, combining precision with practicality.

Materials Used in Aluminum Extrusion Enclosures

Manufacturers use aluminum alloys to produce aluminum extrusion large enclosures. These alloys are lightweight, strong, and resistant to corrosion. They also provide excellent thermal conductivity, making them ideal for a wide range of applications.

Popular aluminum alloys used in this process include 6061 and 6005. These alloys are easy to extrude and provide excellent mechanical properties and processing performance. Their reliability and versatility make them ideal for creating durable and functional enclosures.

Manufacturing Process

The production of large aluminum enclosures through extrusion relies on powerful machinery. Large extruders, capable of handling diameters up to 140mm, are essential for this process. For example, Hugh Aluminum operates a 2400-ton extrusion line that can produce housings with diameters as large as 200mm.

The process begins by heating aluminum alloy to a specific temperature, making it malleable but not molten. Once heated, the process forces the material through a die, shaping it into a shell with a precise cross-sectional design. This step transforms raw aluminum into functional enclosures.

The die plays a critical role in this process. It determines the enclosure’s shape, size, and accuracy. A well-designed die ensures that the final product meets exact specifications and performs as intended.

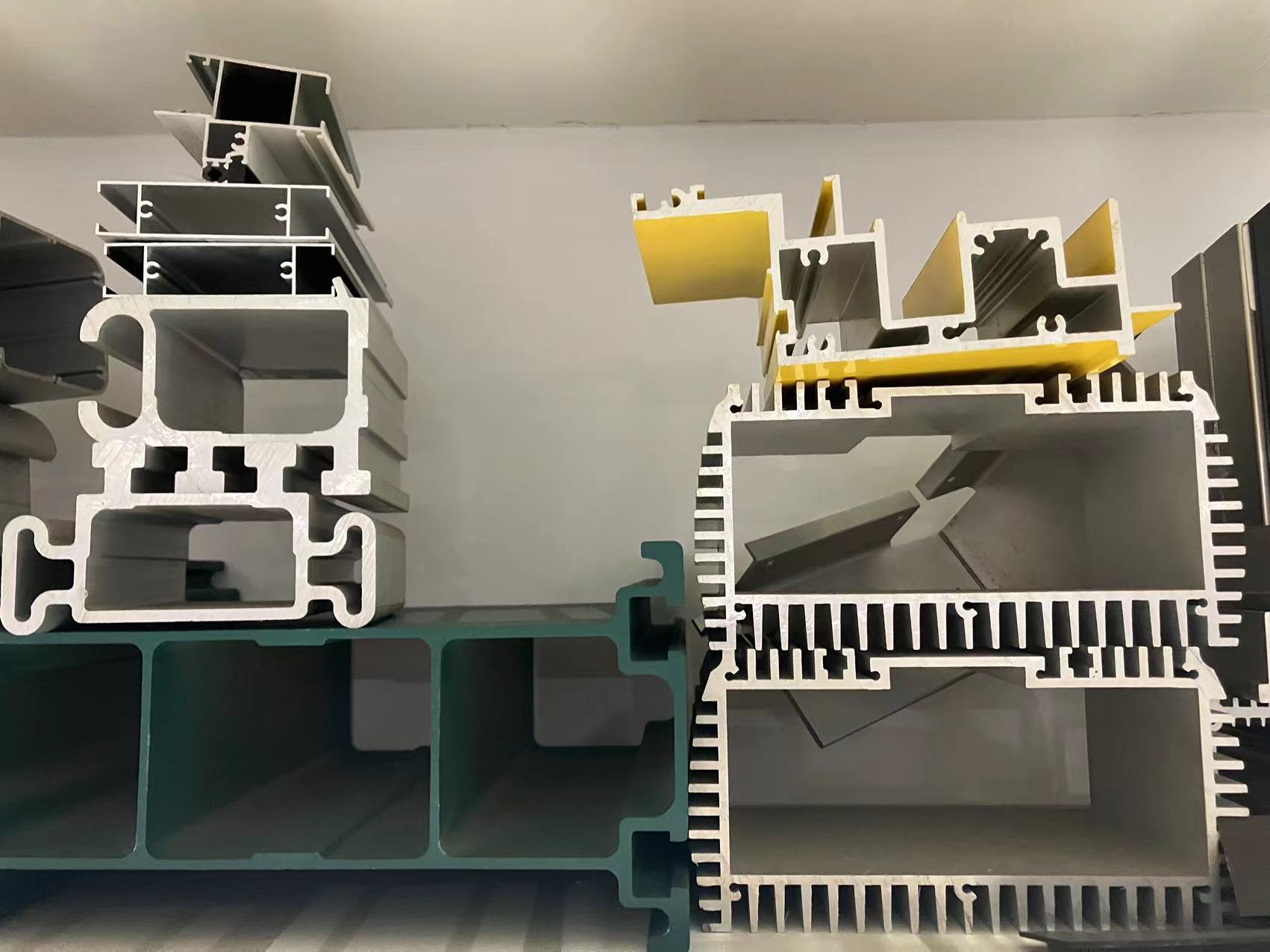

Key Features of Aluminum Extrusion Enclosure Structures

Large aluminum extrusion enclosures typically have a hollow structure with two openings and a single cross-section. This design is straightforward and practical.

The cross-section shape can be customized based on specific requirements. Common options include round, square, and polygonal shapes, as well as more complex designs.

The extrusion process allows adjustments to the wall thickness and cross-sectional shape within defined limits. These adjustments make it possible to adapt the enclosure for various applications, such as enhancing strength or reducing weight.

Customization and Surface Treatment

Aluminum extrusion enclosures can be customized to meet specific project needs. These customizations include adjustments to size, shape, and surface finishes, ensuring the enclosure fits the intended application precisely.

Surface treatments enhance both the appearance and durability of aluminum enclosures. Options such as anodizing, sandblasting, and brushing are commonly used. Anodizing adds a protective layer that resists corrosion and allows for various color finishes.

Sandblasting creates a matte texture, while brushing gives the surface a smooth, polished look. These treatments improve resistance to wear and environmental damage while offering a professional finish.

By combining customization with surface treatments, aluminum enclosures become highly functional and visually appealing, ready to perform in demanding conditions.

Industries and Applications

Various industries widely use aluminum extrusion large enclosures. These enclosures commonly serve as heat-dissipation shells for electronic devices, effectively managing temperature and protecting components. Examples include enclosures for cables, air conditioners, and other equipment requiring thermal regulation.

These enclosures also provide protection for sensitive devices such as hard disk drives, audio systems, and medical equipment. Their durable construction shields internal parts from impacts, moisture, and high temperatures. This makes them essential for ensuring the reliability and safety of critical equipment in demanding environments.

Final Thoughts

Aluminum extrusion large enclosures are manufactured using the aluminum extrusion process. They offer strong material properties and a dependable structure, making them suitable for protecting electrical appliances, equipment, and circuit boards.

These enclosures provide a reliable solution for safeguarding sensitive components in various applications. Their durability and functionality make them essential for ensuring the safety and efficiency of devices in demanding environments.