What are the different aluminum extrusion profiles

There are many types of aluminum extrusion profiles, the following is a clear classification and summary of different aluminum extrusion profiles:

Classification by use:

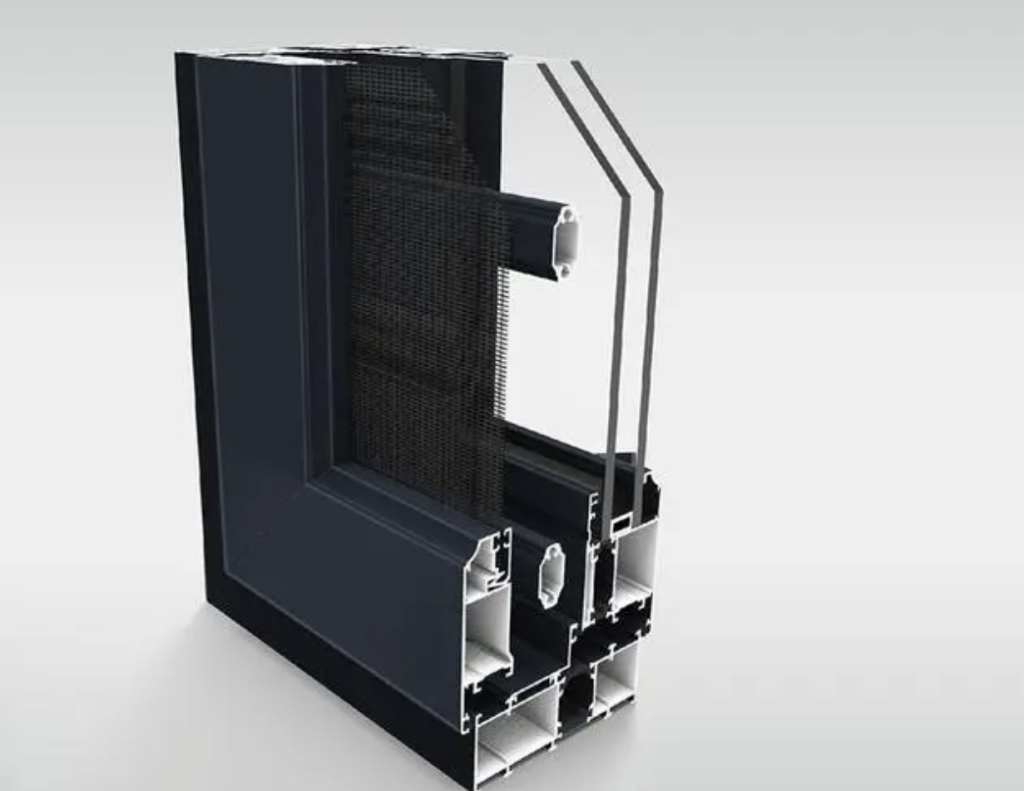

Architectural aluminum profiles:

Suitable for the manufacture of architectural window frames, door frames, etc., with good oxidation and corrosion resistance. For example, 6000 series aluminum profiles. It is suitable for the manufacture of home furnishings, furniture, kitchen utensils, etc. It is characterized by lightness and beauty.

Decorative aluminum extrusion:

We commonly see aluminum picture frames, which are manufactured from aluminum extrusion. It can be used to frame various types of photos and paintings. In addition, there are aluminum decorative borders and aluminum decorative strips. These aluminum products will be used for decorative purposes, to set the mood in an interior or to highlight furniture.

Heat sink:

It is mainly used in the manufacture of heat dissipation equipment. For example, the heat sink of PCB, the heat sink of computer graphics card, the heat sink shell of air conditioner. As well as a variety of LED lights shell.

General industrial aluminum profiles:

- Such as 6061 aluminum profile: it has good workability and strength, widely used in the manufacture of aircraft parts, flatbed lathes, automobile frames and bumpers and other fields.

- 6082 aluminum profile: it has high strength and excellent machinability, widely used in the manufacture of aircraft parts, ship pressure vessels and other fields.

Classification by alloy composition:

Common alloy grades are 1024, 2011, 6063, 6061, 6082, 7075, etc., of which the 6000 series is the most common.

For example, 6063 alloy is a typical representative of (A1 – Mg – Si) system alloys. It has particularly good extrudability and weldability, and is the material of choice for building and door and window profiles.

Classified according to surface treatment requirements:

- Anodized aluminum

- Electrophoretic coating aluminum

- Powder coated aluminum

- Wood grain transfer aluminum

- Fluorocarbon spraying aluminum

- Polished Aluminum

Aluminum extrusion profiles have the following characteristics:

- Corrosion resistance: Aluminum profiles have a low density of about 2.71g/cm³, which is one-third the density of steel, copper or brass. Under most environmental conditions, including air, water, petrochemical and many chemical systems, aluminum can show excellent corrosion resistance.

- Electrical Conductivity: Aluminum extrusions have nearly twice the electrical conductivity of copper (at the same weight).

- Thermal Conductivity: The thermal conductivity of aluminum alloy is about 50-60% of that of copper, and it is suitable for manufacturing heat exchangers, evaporators, heating appliances, cooking utensils, and so on.

- Non-ferromagnetic: Aluminum profiles are non-ferromagnetic, which is an important characteristic for the electrical and electronic industries.

- Machinability and formability: Aluminum profiles have excellent machinability and formability.

- Recyclability: Aluminum has a very high recyclability and the properties of recycled aluminum are almost indistinguishable from virgin aluminum.

In summary

We can classify aluminum extrusion profiles by their use, alloy composition and surface treatment. Different types of aluminum extrusion profiles have their own characteristics. We should plan according to the needs of the building project when choosing it.

Hugh Aluminum is an aluminum extrusion manufacturer based in China. We have extrusion, powder coating, anodizing, CNC and polishing processing capabilities. We are 14 years experienced aluminum extrusion supplier and can offer you factory price and high quality products.