What is 6063-T5 Aluminum Extrusion?

6063-T5 aluminum extrusion is a widely used material in construction and manufacturing. It forms the framework for many doors, windows, and building structures, making it a staple in modern architecture.

But why is it so popular? The answer lies in its balance of strength, versatility, and ease of use. Let’s explore what makes 6063-T5 aluminum extrusion a top choice for many applications.

6063 Aluminum Alloy Composition Explained

6063 aluminum alloy consists of aluminum, magnesium, and silicon as its primary elements. Silicon is present in higher amounts than magnesium, which gives the alloy medium strength. This balanced composition makes it suitable for various applications.

The alloy is heat-treatable, meaning controlled heating processes can increase its hardness and strength. Heat treatment enhances its durability, making it a reliable choice for structural purposes.

Key Performance Metrics and Benefits

Extruded 6063-T5 aluminum is lightweight and strong. Its low density allows for reduced structural weight while maintaining durability. This alloy is easy to work with and offers excellent resistance to corrosion, making it suitable for various applications.

Key performance metrics include a tensile strength of 160 MPa, non-proportional elongation stress of 110 MPa, 8% elongation, and a hardness rating of 8 HW. These properties enable 6063-T5 aluminium to support complex designs and demanding structural requirements effectively.

Heat Treatment State (T5)

The “T5” in 6063-T5 aluminum extrusion refers to a specific heat treatment process that enhances the material’s properties. First, the process heats the aluminum to a temperature between 500°C and 530°C during solution treatment. This step dissolves alloying elements evenly within the metal.

Next, the process rapidly cools the aluminum using water quenching or gas quenching. This cooling process locks the alloying elements in place, ensuring the material retains its structural integrity.

Finally, the process artificially ages the aluminum. This step increases its hardness and strength while preserving its flexibility. The T5 heat treatment makes 6063 aluminum ideal for applications requiring durability without sacrificing workability.

Applications of 6063-T5 Aluminum Extrusion

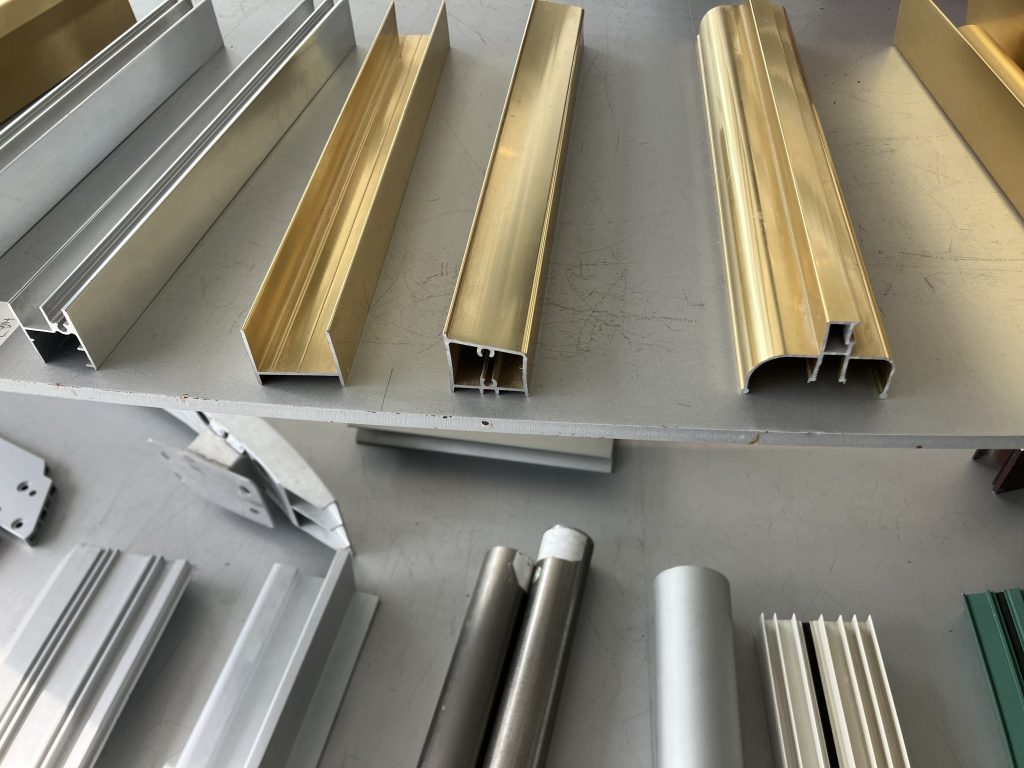

6063-T5 extrusion plays a key role across industries due to its lightweight and strong properties. Manufacturers rely on it to produce mechanical equipment, instruments, and components. Its reduced weight enhances equipment performance and lowers energy consumption. This alloy commonly forms extrusion profiles such as 4040, 2020, and 3030.

In construction, this aluminum alloy serves as a material for door and window frames, curtain walls, and decorative trim. It resists corrosion, enhances building aesthetics, and increases structural durability, making it a practical choice for long-term use.

Beyond construction, 6063-T5 aluminum supports various applications, including heat sinks and battery casings. Its versatility makes it ideal for projects demanding both strength and efficiency.

Economic Advantages

6063-T5 aluminum is a cost-effective material widely used in manufacturing. It has a lower price compared to many other alloys, making it an affordable choice for businesses. Its machinability simplifies processing, reducing production time and costs. Additionally, its recyclability lowers long-term expenses and supports environmentally friendly practices.

This alloy provides excellent value for money. It delivers reliable performance at a competitive price, making it a practical option for industries focused on efficiency and budget management. Manufacturers choose 6063-T5 alloy because it balances affordability with functionality.

Final Thoughts

6063-T5 extruded aluminum is valued for its affordability, versatility, and reliable performance. Its lightweight design, strength, and corrosion resistance make it suitable for a wide range of applications, including construction and manufacturing.

As one of the most commonly used aluminum alloys, 6063-T5 contributes significantly to modern industries. It supports the creation of durable products and structures while remaining cost-effective. This alloy continues to be a practical choice for businesses seeking efficiency and quality.