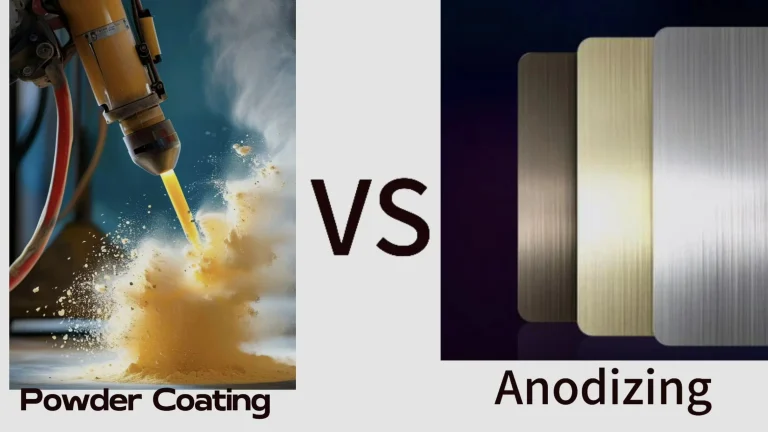

What is the pre-treatment process for powder coating?

Powder coating is an important surface treatment process for aluminum. Reasonable pre-treatment is necessary to obtain a beautiful powder coating.

So what is powder coating pretreatment?

Surface cleaning:

1. Its purpose: to remove grease, dust and other impurities from the aluminum surface to ensure the quality of spraying.

2. Methods:

- Use solvent or special cleaning agent for cleaning.

- The choice of cleaning agent should be based on the degree and type of contamination on the surface of the aluminum profile.

- After cleaning, it should be ensured that the aluminum surface is dry and free of oil and impurities.

Surface pretreatment

1. Purpose: To increase the adhesion and durability of the spray coating with the aluminum surface.

2. Chemical treatment:

Acid washing: Remove the oxide layer and other impurities on the surface of aluminum by acid solution.

Chromic acid treatment: further clean the aluminum surface and improve the adhesion of coating.

Pay attention to control the treatment time and solution concentration to avoid excessive corrosion of aluminum.

Mechanical treatment:

- Sanding: use sandpaper or grinding wheel to remove the uneven part of aluminum surface and improve the surface roughness.

- Mechanical sanding: further increase the surface roughness and improve the contact area between the paint and the aluminum surface.

Belows video shows powder coating processing:

Rust removal and grinding and polishing

1. Purpose: Ensure the surface of aluminum profile is free of rust and improve the quality of spraying.

2. Methods

- Rust removal: Use rust remover or mechanical methods to remove rust from the aluminum surface.

- Grinding: Grind and polish before removing rust to ensure that the rust remover can fully penetrate the surface of aluminum profiles. o Be careful not to overdo it when grinding and polishing.

- Care should be taken not to over-treat when grinding and polishing to avoid destroying the integrity of the aluminum surface.

Anti-corrosion treatment

1. Purpose: To extend the service life of aluminum surface.

2. Methods

- Anodic oxidation: form a layer of dense oxide film on the surface of aluminum to improve corrosion resistance.

- Chemical chrome plating: Form a layer of chrome plating on the surface of aluminum to improve abrasion and corrosion resistance.

- The specific choice of anti-corrosion treatment should be determined according to the use of aluminum profile environment and requirements.

Drying treatment

Use hot air gun, drying equipment and other methods to dry the aluminum surface thoroughly.

The time and temperature of drying treatment should be determined according to the material and thickness of aluminum.

Precautions

1. When carrying out surface treatment, safety measures must be taken to avoid the use of flammable and toxic chemicals.

2. when carrying out chemical cleaning, degreasing, rust removal and other steps, pay attention to the control of time, concentration and temperature to avoid damage to the aluminum profile.

3. Check and maintain the spraying equipment regularly to ensure that it is in good working condition.

The above is the pretreatment process of powder coating. Please note that not all powder coating requires pre-treatment. The use of this process should pay attention to the safety of personnel, because this process has a certain degree of danger.

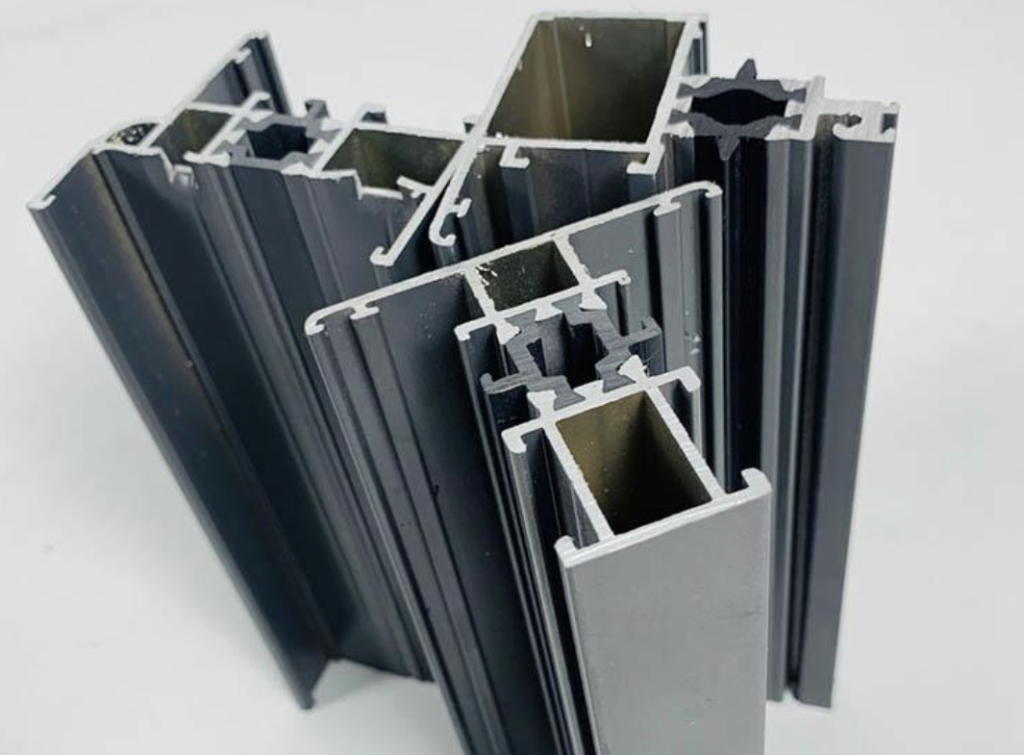

Hugh Aluminum is an aluminum extrusion manufacturer based in China. We have extrusion, powder coating, anodizing, CNC and polishing processing capabilities.