How to Cut Aluminium Extrusions:method and tools

What is aluminum extrusions?

Aluminum extrusion is a processed aluminum technology used to make aluminum alloys into specific shapes for different applications. It works by heating aluminum until it becomes soft and then pushing it into specially shaped openings in a die, which determines the final shape of the extruded aluminum profile.

This processing method takes advantage of the softness of the aluminum metal, allowing it to be extruded into a variety of complex shapes. Its hardness and strength can also be increased by adding other metal components, such as aluminum grades 6063 and 6005.

When cutting aluminum extrusions. We need to follow certain steps and precautions to ensure safe operation and accurate cutting. The following are the detailed steps and precautions for cutting aluminum extrusion products.

Cutting methods for aluminum extrusion:

1. Mechanical cutting:

- Definition: A method of cutting aluminum using a mechanical shear.

- Scope of application: It is suitable for straight line cutting and can realize high precision cutting.

- Cautions: For cutting complex curves or bending aluminum profiles, other cutting methods may be required.

2. Thermal cutting:

- Definition: A method of cutting aluminum by means of a high-temperature cutting tool.

- Scope of application: Suitable for larger thicknesses of aluminum, high precision and small cutting widths can be maintained.

- Cautions: High temperature heat and sparks are generated during the cutting process, and fire prevention measures must be taken.

Which saw is best for cutting aluminum extrusions?

There are many types of cutting saws available in the market. Here are some of the most popular saws used for different cutting styles of aluminum extrusions:.

- Miter saws

- Circular saws

- Table saws

- Diamond Cutting Saws

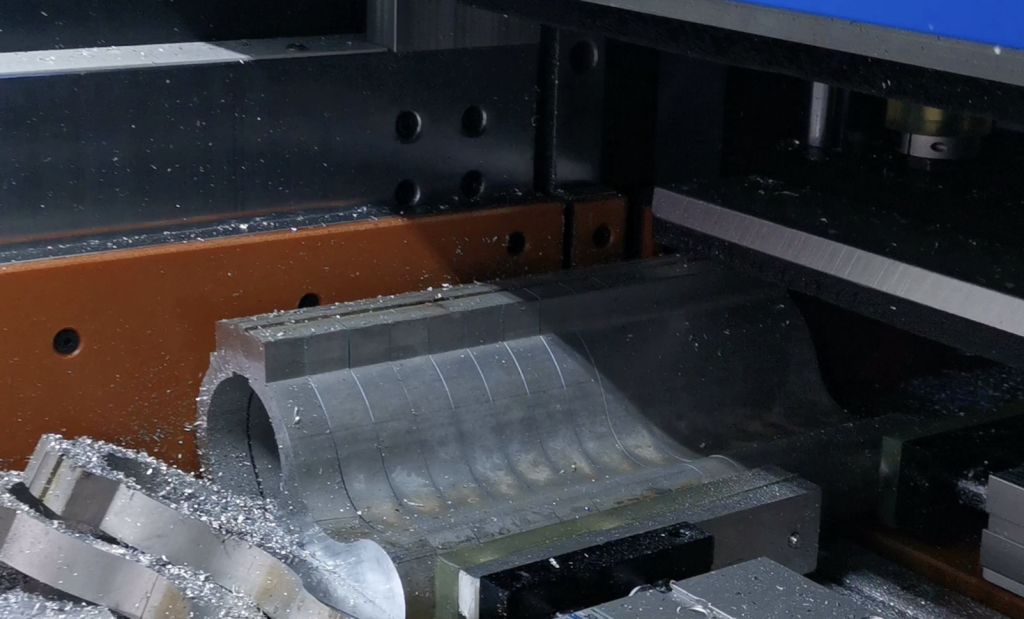

- CNC cutting saws

The best saw for cutting aluminum depends on the type of aluminum you are cutting and its thickness. People usually use miter saws and circular saws more often. This is because these two saws are less expensive and do not require a long time to learn. You just need to follow the saw blade and then cut according to the length.

The steps of cut aluminum extrusion

1. setting up the saw:

Install the saw blade to the machine according to the instructions and check that the blade is trimmed. If we need to cut large aluminum extrusions or profiles, we have to place the saw on the floor. Keep open and dry areas where the saw can work better. During this step, we cannot plug in the power supply.

In addition, if you are using a CNC cutting or motorized cutting machine. Then, we need to set the angle and length of the cut in advance on the computer or console. Check the integrity of the saw blade after setting the parameters of aluminum profile cutting.

2. Marking cut points or lines:

Measure from the end of the aluminum piece to where you want to cut and make a mark. Using a tape measure or caliper, draw the cut point on the extrusion at the mark. Measure the length of your cut again. You can mark your cut line using your favorite marking tool, such as water-based markers, paint pens and pencils.

3. Clamping the workpiece:

The teeth on the blade are offset and you need to find the longest tooth on the blade that faces the part you don’t want to cut. Then align that tooth with the side of the cut line where you want to remove material. Clamp the workpiece in place. If your saw has a removable clamp, that would be perfect. You just need to use the jig to hold the aluminum extrusion in place and then move the end to test for firmness. Once this is done we can start cutting.

4. cutting

The cutting process is simple. Plug in the saw and now place your hand on the trigger to make the cut. The cut should be made slowly, allowing the blade to finish the job. Do not force the blade down, just press gently.

Unplug the saw after completing the cut. Release the workpiece and measure. If you are making another cut, use an air gun to clean the table of aluminum debris. This is because the debris will affect the accuracy of the cut and may hurt your eyes during the cutting process.

5.Cleaning up messes and trash

When you have finished cutting, you can use a vacuum cleaner or broom to clean up the aluminum powder left behind by the cutting. Remove the saw blade to clean the surface and remove any dust from the saw machine. If you cut leftover aluminum workpiece, take it away because sharp aluminum profiles can cut people.

Precautions:

1. In the operation process, strictly observe the safety operation regulations. Staff wear protective equipment to ensure their own safety.

2. Pay attention to controlling parameters such as cutting speed, pressure and angle. The operation needs to ensure that the cutting quality meets the requirements.

3. Staff should regularly maintain and repair the cutting tools. Keep it in good condition and prolong its service life.

Here are the cut aluminum extrusions!

Cutting aluminum extrusion products need to choose the appropriate cutting methods and tools. However, when you are faced with a large number or size of aluminum extrusions cutting them by yourself is impossible.Hugh Aluminum can help you to get all kinds of cut aluminum extrusions, we are an aluminum extrusion factory with 14 years of production experience.

Our professional team provides you various styles of aluminum extrusion products!

Hugh Aluminum is an aluminium extrusion plant. We offer a design to production service.

We have 14 years of production experience and have served over 600 customers from forty countries.

If you want to purchase aluminium extrusion products in bulk or looking for a good supplier.

Please contact us!