What is Aluminum Hat Channel? Features, Uses and More

Aluminum hat channels are a versatile building material used in construction and interior design. Their shape and strength are perfect for framing and decorative applications. Knowing the features and benefits of aluminum hat channels will help you make an informed decision for your projects.

In this article, we will cover everything you need to know about aluminum hat channels. We will talk about their design, common uses, and advantages over other materials. Whether you are a contractor, designer, or DIYer, this guide will give you the knowledge to use aluminum hat channels in your work.

Read more: Aluminum Channel Types and Their Uses

What is the Aluminum Hat Channel?

Aluminum hat channel is a useful material for wall finishes and ceiling projects (aluminum ceiling panel). It is commonly used in basement renovations but has many other applications. The name “hat channel” comes from its shape, which resembles a hat.

Key Features of Aluminum Hat Channel

Construction workers favor aluminum hat channels for several reasons. They provide a cost-effective way to level walls. Additionally, they protect the interior framing of walls from moisture, corrosion, and pests.

Hat channels are made from grooved aluminum, which offers excellent corrosion resistance. This quality makes them suitable for various architectural and decorative uses. For instance, they can serve as a protective layer for LED light strips.

How Aluminum Hat Channels Are Made?

Aluminum hat channels are made through a process called aluminum extrusion. This method shapes aluminum by forcing it through a die. Think of it like squeezing toothpaste from a tube; as you apply pressure, the toothpaste takes the shape of the opening. In this case, high pressure pushes the aluminum through the die to create the desired profile.

The process begins with heating an aluminum billet. This makes the metal easier to shape. The heated billet is placed in an extrusion press. A powerful ram then pushes the aluminum through the die, using up to 15,000 tons of force. As the aluminum flows, it fills the shape of the die and emerges as a finished channel.

Aluminum hat channels have a unique hat-like shape. They feature two horizontal flanges that extend outward and two vertical legs. Manufacturers can customize these channels in various sizes and thicknesses, typically from 0.005” to 0.150”, to fit specific needs. After extrusion, channels may be treated further, such as through quenching or anodizing, to improve their strength and durability.

Making aluminum hat channels is a blend of engineering and creativity. This process transforms raw aluminum into useful components for construction and other applications. Whether you’re building a structure or crafting a project, these channels play an important role in providing support and stability.

Aluminum Hat Channel Structure

Aluminum hat channels have four main parts:

- Bottom: The bottom is the base of the channel. It provides a flat or slightly curved surface for mounting on walls, frames, or other structures. This part is strong enough to support the intended load.

- Sidewalls: The sidewalls are vertical or slightly sloped. They rise from the bottom and form the sides of the channel. Their height and angle can change based on specific needs.

- Cap Top: The cap top resembles a cap or gentle curve. It adds extra support and protection to the channel.

- Openings: The opening is located between the bottom and sidewalls, creating a long space in the center of the channel. Its size and shape can vary based on application needs. This opening helps contain, secure, or guide materials like wires, LED strips (LED Aluminum profile), and insulation.

Each part of the aluminum hat channel serves a specific purpose. This structure allows for flexibility in various applications, making it a favored choice in construction and design projects. Whether you’re building or organizing, these channels provide reliable support and functionality.

Aluminum Hat Channel Applications

Aluminum hat channels have many practical uses, especially in architecture and interior design. Here are some common applications:

Pipe and Wire Installation

Hat channels are excellent for installing and securing pipes and wires. They serve as part of cable trays or pipe supports, providing stable support and protection. The openings in the channel fit various sizes of pipes and wires, making connections to other structures simple.

Decorating and Partitioning

These channels are often used to create decorations and partitions. Their cap top adds a distinctive look that enhances any space. You can mix hat channels with different materials for both style and function. They also work well as space dividers, helping to organize larger areas.

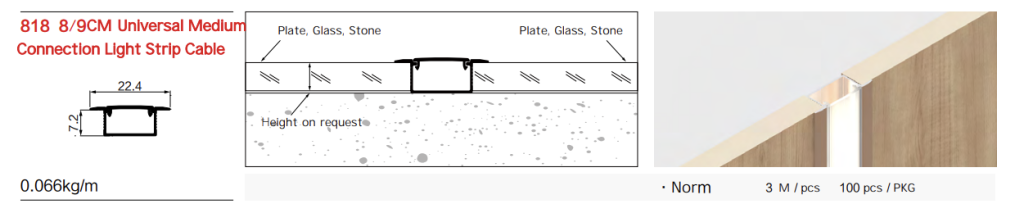

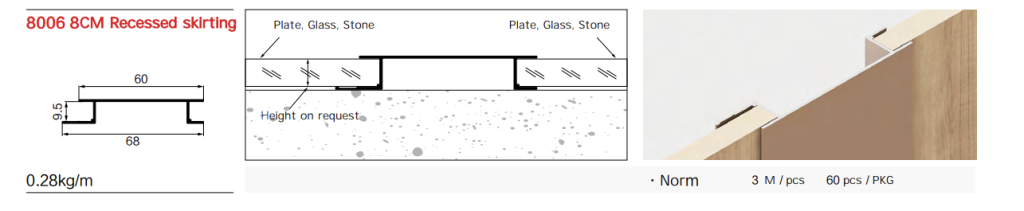

Connecting Boards, Facades, and Glass

Contractors frequently use hat channels to connect boards and glass in construction projects. The L-shaped contact surfaces on both sides allow for easy attachment with nails or adhesive. In garages or basements, you can install hat channels above the ceiling to hold LED lights, brightening the area while keeping it tidy.

Aluminum hat channels are versatile tools in construction and design. Their strength and flexibility make them popular for various applications, from structural support to decorative elements. Whether building or decorating, these channels help you achieve your goals effectively.

Related products: Extruded aluminum channels

Final Thoughts

Aluminum hat channels are important building materials with a functional design. They meet the needs of interior design and can improve the look of any space.

Hugh Aluminum manufactures aluminum hat channels in various types to fit different applications. Whether you need them for support or decoration, these channels offer reliable solutions for your projects. Choose aluminum hat channels to enhance your next construction or design endeavor.

Read more: The Ultimate Comparison of Aluminum Channels