How to improve aluminium extrusions hardness

To improve the hardness of aluminium extrusions, you can start from the following aspects:

1. Optimising the extrusion process:

Cold working, hot working and post-processing in the extrusion process will have an impact on the hardness of aluminium.

By optimising the extrusion process, the deformation stress in the extrusion process can be reduced. Reduce the difficulty of extrusion deformation. This can avoid cracks and damage on the surface of aluminium profiles, thus improving the hardness of aluminium.

Control the aluminium extrusion process parameters. Such as billet temperature, die preheating treatment temperature, extrusion speed and extrusion ratio.

For example, for 7075 aluminium alloy material, a billet temperature of 400°C and appropriate die preheating treatment temperature can be selected. As well as the appropriate extrusion speed and extrusion ratio, and at the same time choose the appropriate lubricant, such as molybdenum dioxide.

2. Adjustment of alloy ratios:

The amount and type of alloying elements added will affect the strength and hardness of aluminium extrusion. If the hardness of aluminium extrusion is not enough, you can adjust the alloy ratio. Increase the content of strengthening elements to improve the strength and hardness of the alloy.

3. Ageing treatment:

The aluminium alloy is first heated to solid solution temperature to dissolve the alloying elements in the aluminium matrix, and then the solid solution is rapidly cooled.

Then the solid solution is rapidly cooled, followed by aging treatment at a certain temperature to precipitate the solute elements and form diffuse strengthening phases to improve the strength of the aluminium extrusion.

4. Ageing insulation of aluminium extrusions:

Strictly follow the process requirements to carry out aging. The holding time should be appropriate to prevent under-ageing or over-ageing which may lead to insufficient hardness.

Belows video from Hugh aluminium shows whole process of aluminium extrusion:

5. Aluminium extrusion framing and temperature control:

The framing of aluminium extrusion profiles should not be too dense. There should be spacing between materials, especially for small and thick materials which are not ventilated.

Temperature setting and control is also very important, set the table temperature should be set according to the actual temperature of the furnace, and pay close attention to the temperature fluctuations.

6. Alloy categorisation:

For 6xxx series of special alloys and ordinary 6063 alloy. Before loading the furnace need to separate loading furnace aging. If aging in the same furnace is really needed, the aging treatment should be carried out by the process of special alloy.

In summary

Enhancing the hardness of aluminium extrusion requires consideration of the following factors: extrusion process, alloy ratio, solution treatment and aging treatment, aging heat preservation, framing and temperature control as well as alloy classification treatment and many other aspects.

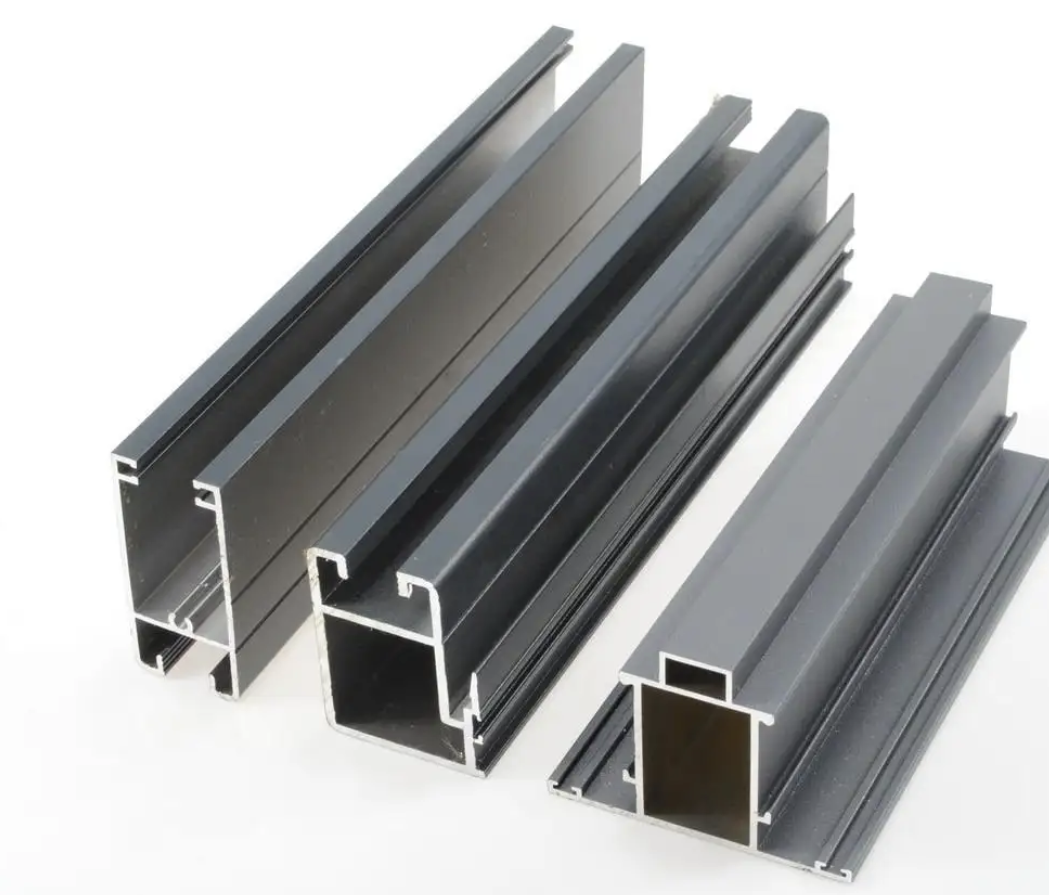

Hugh Aluminum is an aluminum extrusion manufacturer based in China. We have extrusion, powder coating, anodizing, CNC and polishing processing capabilities.