How are aluminium decks made?

The manufacturing process of aluminium decking consists of the following key steps, which are explained and summarised in detail below:

1. Material preparation:

The main material for aluminium decks is an alloy material made of aluminium mixed with other metal elements such as magnesium, manganese and titanium.

These alloy materials have good wear resistance, corrosion resistance and high strength. Common aluminium deck materials are 6063 aluminium alloy or 6005 aluminium alloy.

2. aluminium deck production process:

1. Melting and casting:

Aluminium ingots are melted and cast directly into aluminium rods through a specific casting process. This step is the basis of aluminium deck manufacturing and provides the raw material for subsequent processing. 2.

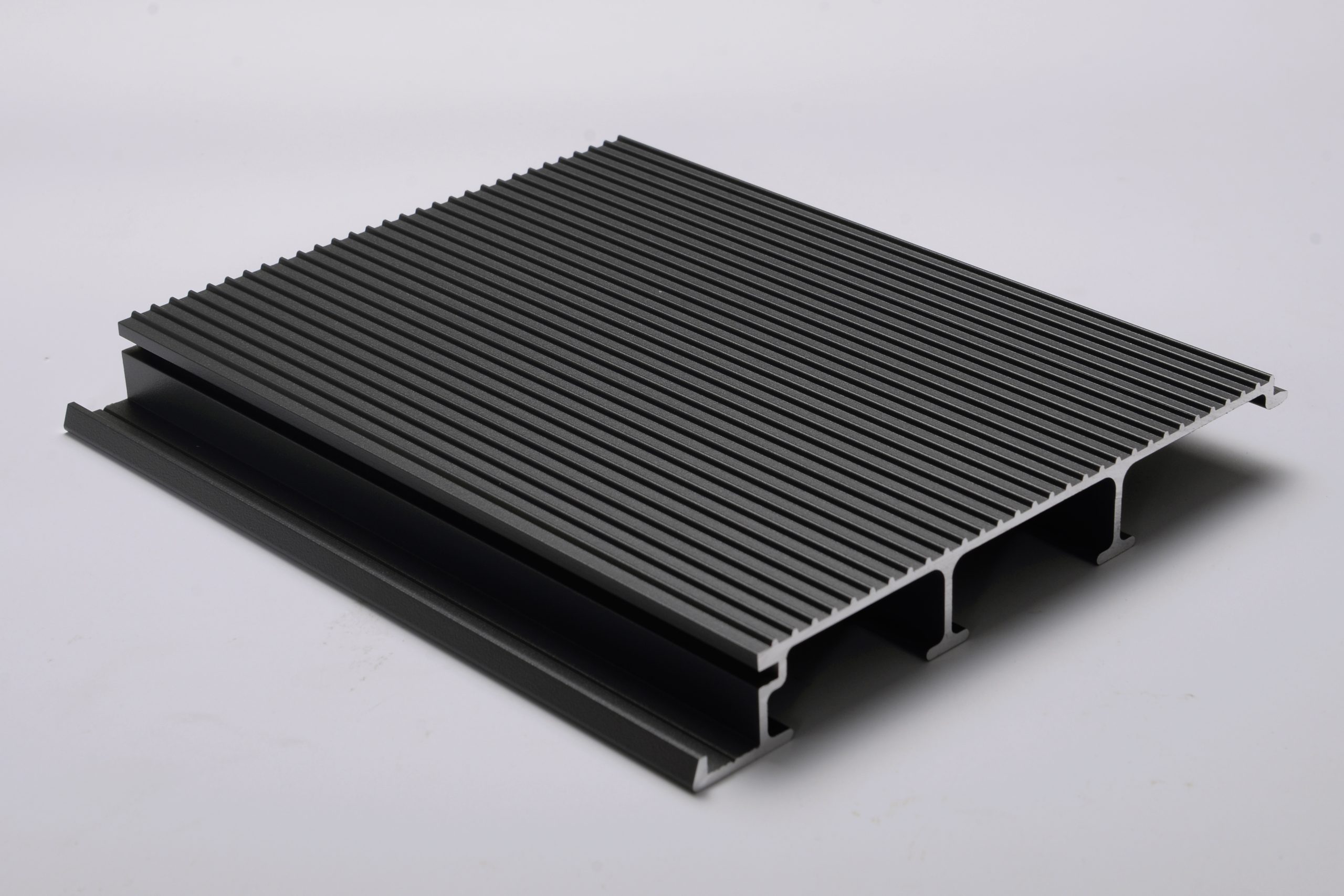

2. aluminium extrusion:

A mould is manufactured according to the design of the shape of the deck.

The heated cast rods are extruded through an extruder to form the desired shape. This step is a critical part of aluminium floor forming and determines the final appearance and size of the floor.

Below is the aluminum decking processing video:

3. Cutting and punching:

Aluminium decking is generally cut by methods such as mechanical cutting or laser cutting. It will choose the appropriate cutting method according to the actual need.

The cut aluminium decking may also need to be stamped through a stamping die to form more complex shapes or structures.

4. Other processing:

According to the specific needs, aluminium flooring may also need other processing treatment. Such as punching, tapping, bending and so on.

This needs to be followed up with processing according to the building project, if it is used as a dock deck it needs to be aged to ensure its strength.

Subsequent surface treatment and quality inspection

After the above processing steps, aluminium flooring also requires surface treatment such as powder coating and anodising. These surface treatments give the surface of the decking a coating, which acts as a protective and anti-corrosive layer.

Finally, the finished aluminium decking is quality checked to ensure that it meets the relevant standards and requirements.

Through the above steps, the manufacturing process of aluminium decking is completed.

It should be noted that the manufacturing process of aluminium decking requires strict control of the parameters and quality of each link. When we buy aluminium decking, we need to pay attention to whether its manufacturer strictly requires the above steps for manufacturing.

Hugh Aluminium is the manufacturer of Aluminium Decking.We design and manufacture all types of aluminium deck.

If you need to purchase aluminum deck in bulk or looking for aluminium suppliers?

Please contact us! We have 14 years of manufacturing experience and served more than 600+ customers from 40+ countries. Our team is friendly and professional.

Please contact us!