Four ways to bend aluminum angle

Why we need bending aluminum angle?

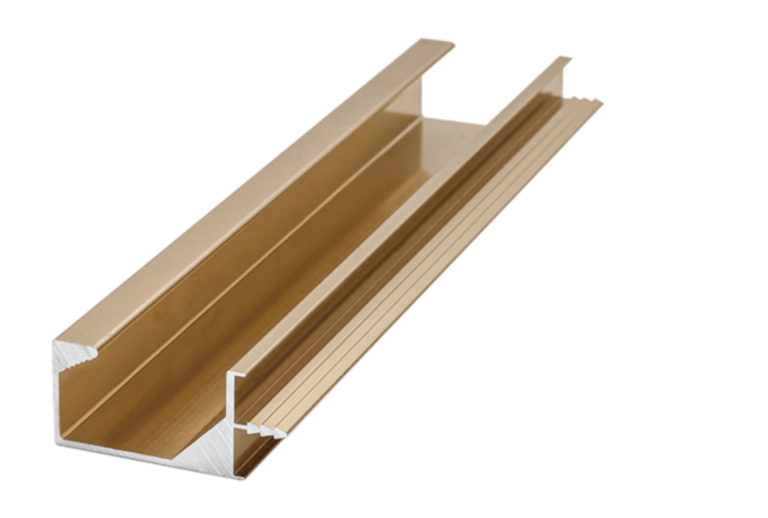

Aluminum angle is a versatile metal material. It is able to function as a decorative material in construction projects. In addition, it can be used as a material to protect equipment. If you need to make some aluminum corners at different angles. It is likely that you are going to need aluminum angle that is bent into a specific curved shape.

However, since aluminum corners contain alloying elements. It is not as simple as simply forcing the metal to bend. If you force bend aluminum angle, it will break or splinter.

With this in mind, the method on how to bend aluminum corners is complex. To avoid damaging aluminum corners, Hugh Aluminum has compiled a list of four ways to bend aluminum corners:

1. Bending by hand or with a wrench

The first method is suitable for small and simple aluminum corners. In case of larger sized aluminum corners or large bending angles. It is difficult to break the bend manually. Below are the steps to break and bend aluminum corners manually/ or with a wrench.

Tools we need to use: wrenches, angle rulers, gauges and equipment for fixing aluminum corners.

- Use an angle ruler and gauge to accurately measure the length of the aluminum corner and the angle at which it needs to be bent.

- Place the aluminum angle on a tabletop. Make sure it is securely fastened to prevent it from sliding during the bending process.

- Apply appropriate pressure or force to bend the aluminum angle along the predetermined angle. I can use a wrench to increase the pressure.

- After bending, use an angle ruler to check that the aluminum corner is bent at the desired angle and make any necessary adjustments.

2. Bending aluminum angle using heat

Since aluminum metal is like any other metal. It will soften at a certain high temperature, so we can soften the aluminum angle by increasing the temperature. Bending after softening.

It is important to note that raising the temperature to melt aluminum metal is dangerous. An ordinary person cannot do this job at home. It needs to be done with the help of specialized equipment and safety gear.

The aluminum angle to be bent is placed in the heating equipment and heated to the appropriate temperature. The choice of temperature depends on the type and thickness of the aluminum alloy, and you need to avoid overheating that could result in melting or loss of performance. Therefore we also need a thermometer.

The bending operation is carried out using a hot bender or specialized tools. Since the aluminum has softened, more precise control of the bending force and angle is required.

After bending, wait for the aluminum to cool down to room temperature, then check the bending results and make any necessary adjustments.

To avoid danger. This method requires finding an aluminum manufacturer or fabricator to do the breaking.Hugh Aluminum can help! We have 1200 tons of bending and processing equipment with bending aluminum extrusions and all types of aluminum angles.

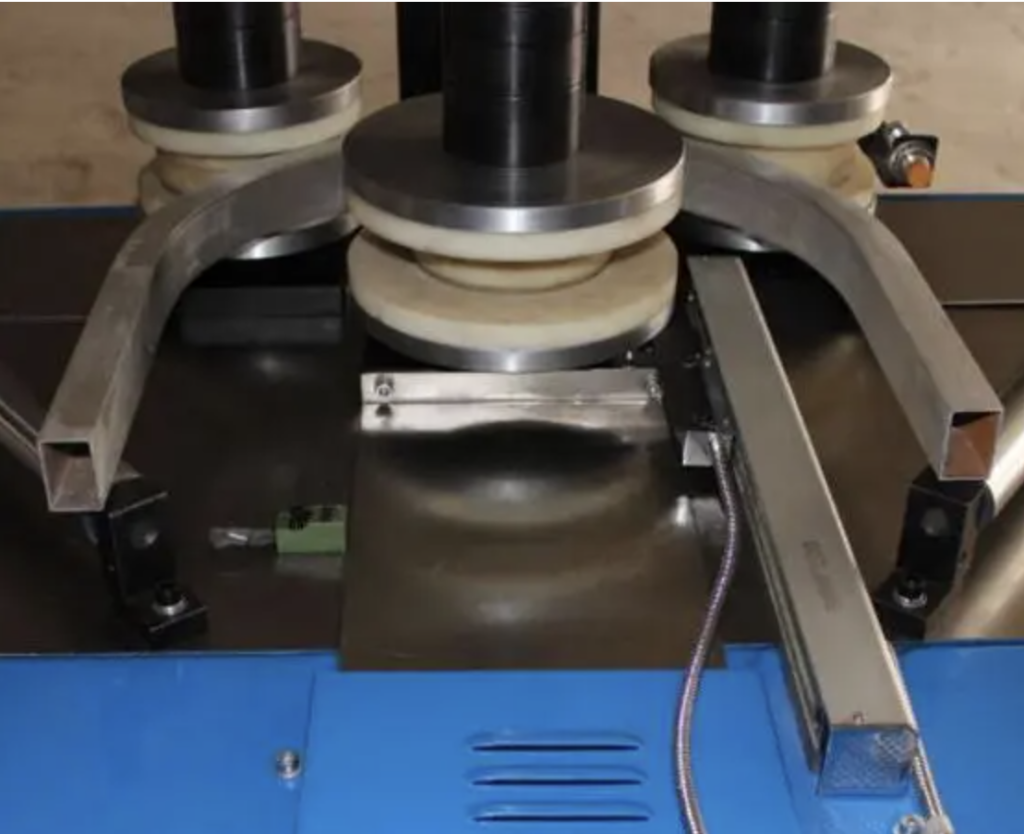

3. Bending aluminum angles with tensioners

What is a pull bending machine?

A draw bending machine is a specialized metal working machine that is used to bend metal materials into desired shapes and sizes. It realizes the bending processing of metal materials through the synergistic action of the main body, slider, guide rail, fixture and other components.

It bends aluminum angle in the following process:

Fixture fixation: the metal material is firmly fixed by the fixture to ensure that it will not move or deform during the bending process.

Slider movement: the slider slides on the guide rail of the main body and drives the fixture and the fixed metal material to move together.

Bending and molding: Through the sliding of the slider, the metal material is bent at a predetermined position and angle to achieve the desired shape and size.

Points to note

Although this is the best way to break and bend aluminum corners. But it will leave jaws on both sides of the aluminum metal. When breaking and bending some aluminum alloys, such as Aluminum Alloy 7075 or 2024 will break. This is because of the risk of stress fractures in harder aluminum alloys.

4. Obtaining curved aluminum angles by welding

This method is not usually used directly for bending aluminum corners. Instead, the effect of breaking the bend is obtained by welding two cut aluminum angle.

It can look like this:

Before welding we need to prepare

Cut two aluminum corners or multiple aluminum corners at different angles. It can be cut at a 45 degree angle along the cross section. This can make it easier to weld.

On the cut aluminum angle, carry out pre-treatment. Such as cleaning the welding area, removing the oxidized layer, and so on. These steps can make the connection of aluminum angle welding better.

Points to note when welding aluminum angle:

Use welding methods and equipment suitable for aluminum (e.g. TIG welding, MIG welding, etc.). Parameters such as welding temperature, welding speed and welding current need to be controlled during the welding process to ensure welding quality.

What is the best way to bend aluminum angle?

There is much debate about the best way to bend aluminum. This is because it depends entirely on the thickness of the aluminum you are using, the tools available, and the angle at which you need to bend it.

If you’re confident with your tools, it’s entirely possible to do it yourself DIY using a wrench. But the truth is that breaking and bending using a bending machine would be the best option.

This is because it is capable of accomplishing the bending at a precise angle. It will be the excellent solution when you don’t know how to bend aluminum metal.

Hugh Aluminum is manufacturer of aluminum angles. We can design and processing all type of aluminium angle. If you wanna bulk buy aluminum angle or looking for best aluminum supplier?