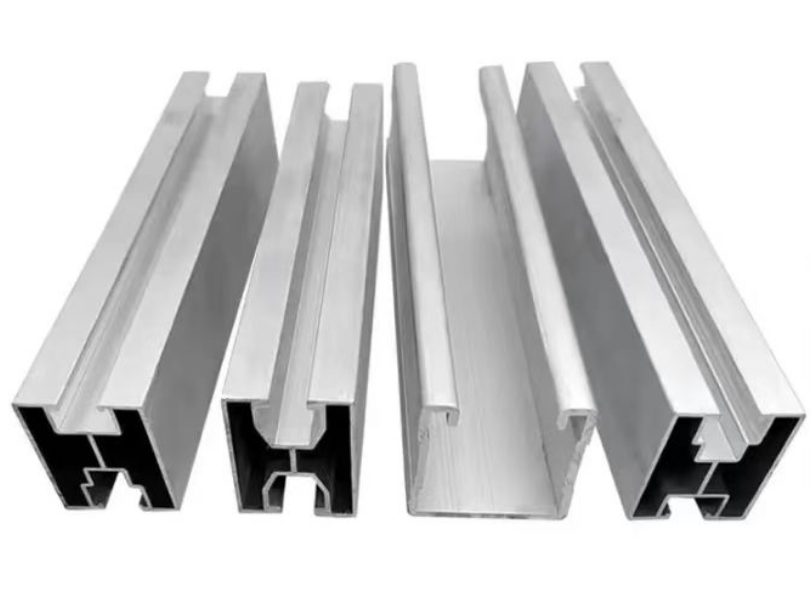

Aluminium Extrusion profiles: Innovative Aluminium solutions

The widely used aluminium is the new star in the construction tasks. We get rid of the disadvantages of aluminium and to improve its advantages to fit for the various requirements of construction target, such as building, decorating, painting or shaping. The aluminium extrusion profiles are being hot in architecture jobs. What is the aluminium extrusion? Normally, we have several methods to make the aluminium being the right external forms. The aluminium extrusion is one of the methods.

The procedure of making aluminium extrusion profiles

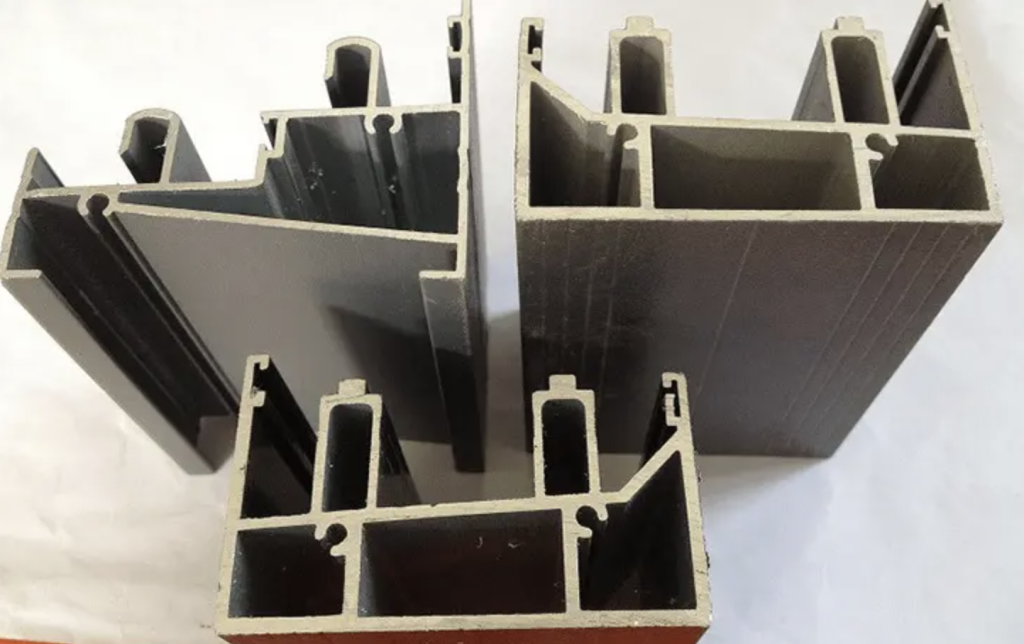

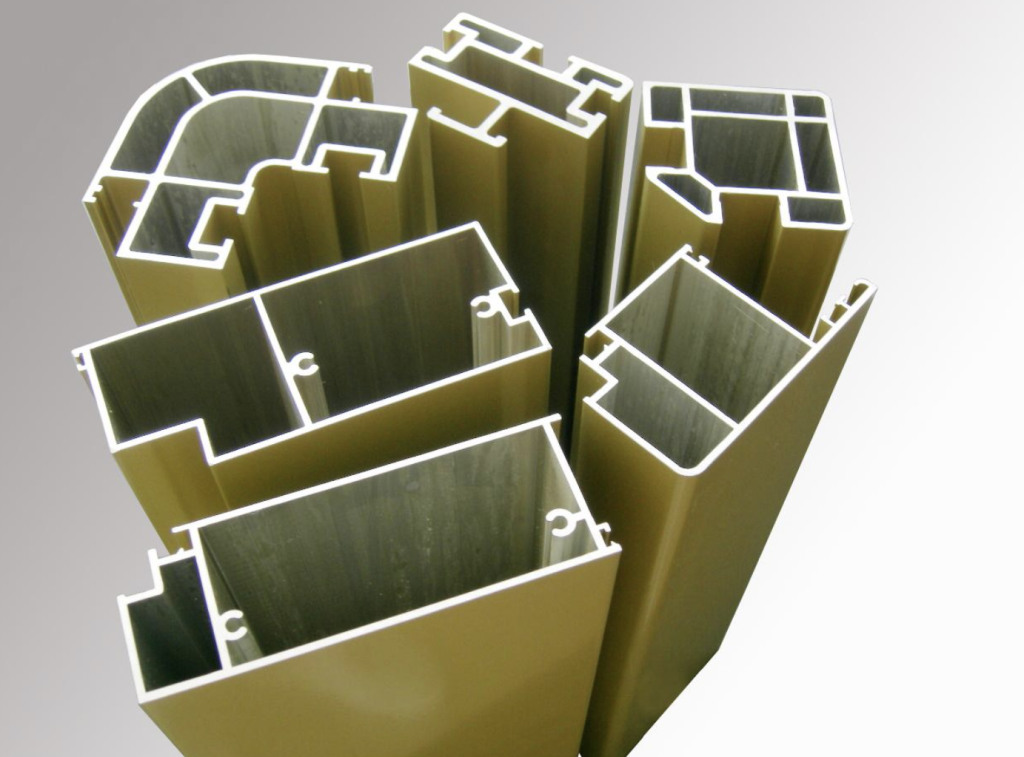

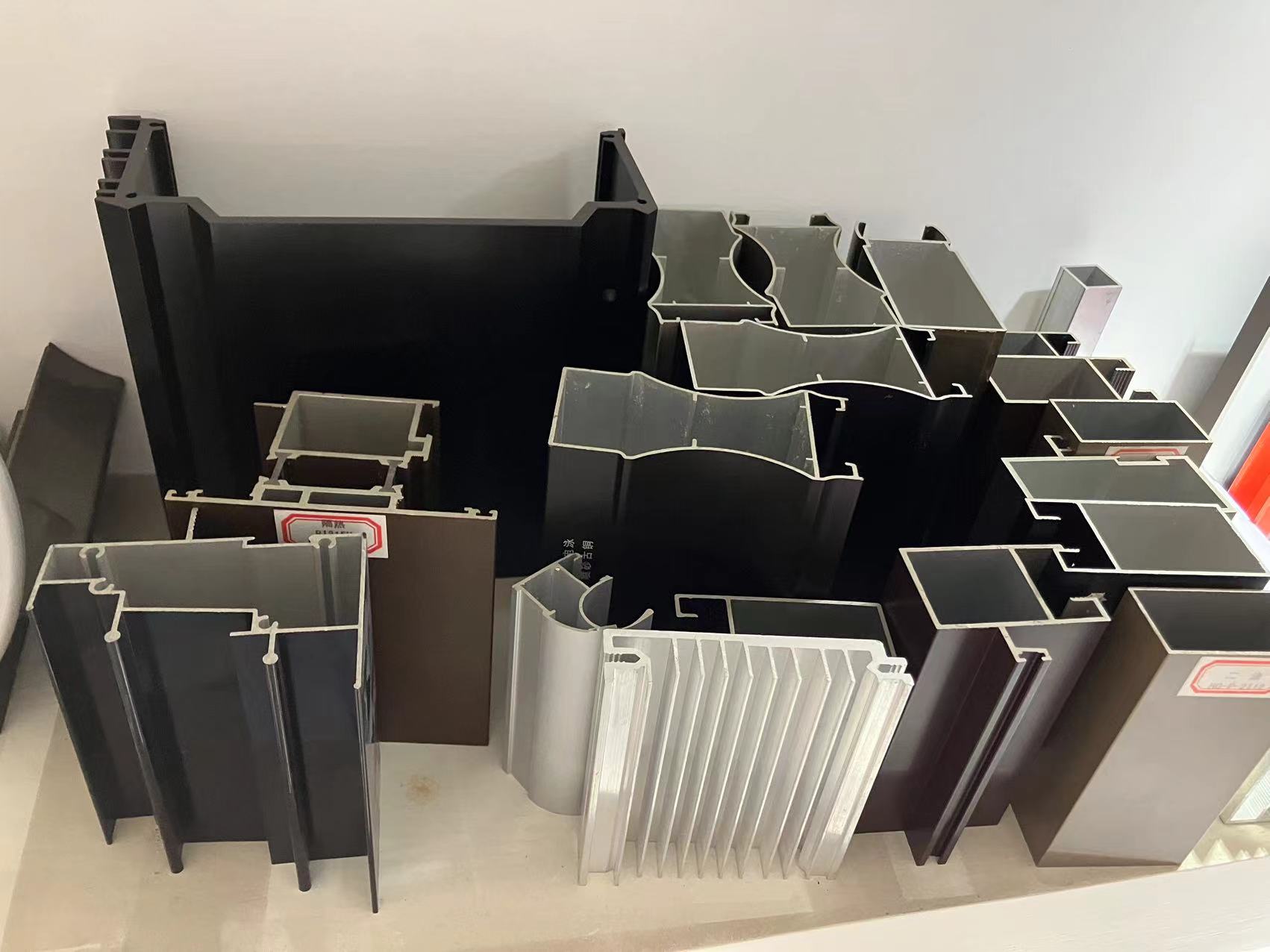

To make aluminium extrusion profiles should have a extrusion machine first, and then, you need have different models. The first step is to melt the aluminium. As we know, the aluminium is a soft elements in metals. The density of aluminum is very small, only 2.7g/cm³.Thus, we can use machine to melt it easily. While its shape is being liquid, we can make it go through the models. Also, we can use the pressure of the machine to make the shape firmly. Then cooling the profiles down, we can have the aluminium extrusion profiles. There are two kinds of aluminium profiles, normal types and required types. They depends on the needs that the customer asked.

The uses of aluminium extrusion profiles

The uses of aluminium extrusion profiles focus on its traits, especially for lightweight and corrosion resistance.

Because of its light weigh, the aluminium extrusion profiles are widely used in manufacturing industries such as aircraft, automobiles, trains, and ships. You can find them in space rockets, spacecraft, and artificial satellites. For example, in shipbuilding, there are several thousand tons of aluminum within a large passenger ship.

The aluminum is flexible because of its good ductility, so you can make it thinner than 0.01mm at temperatures between 100 ℃ and 150 ℃. These aluminum foils can be packaging cigarettes, candies, etc.

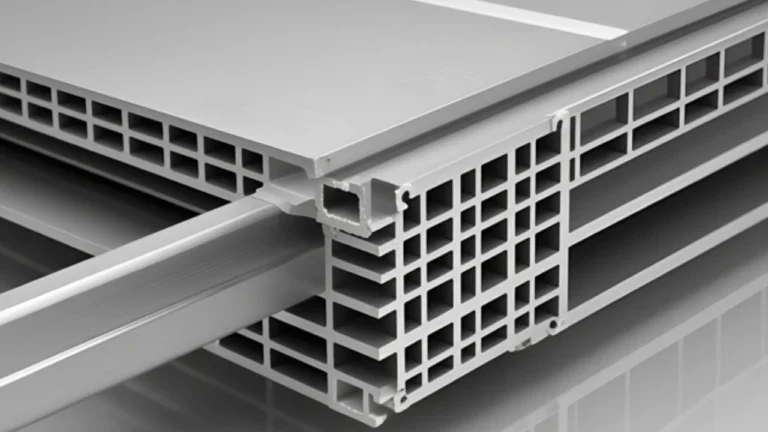

In addition, the aluminium extrusion profiles also can be built or places in the higher situation. They can be the frame of ceiling or being roof. They can be ornaments in any places besides the top wall of the high buildings.

Corrosion resistance is not the only traits. The aluminium extrusion has certain degree of insulation, so aluminum has a wide spread in the electrical manufacturing industry, wire and cable industry, and wireless industry. The chemical reactors, medical devices, refrigeration equipment, petroleum refining equipment, oil and gas pipelines are required to use the aluminium material for sure.

Aluminum plate also has good light reflection performance, reflecting ultraviolet rays stronger than silver. The purer the aluminum, the better its reflection ability.Also, it has sound-absorbing properties and good sound effects, so ceilings or partitions in individual rooms are also made of aluminum. Do not forget, it has resistance to low temperatures too. These resistance traits push it to develop and spread quickly and widely.

Of course, we still can use alloys to make it into various aluminum alloys such as hard aluminum, ultra hard aluminum, rust proof aluminum, cast aluminum, etc. At that time, you may not easily recognize they are aluminium extrusion profiles.

The differences between aluminium extrusion profiles and regular aluminium profiles

The differences between aluminium extrusion profiles and regular ones are the producing methods and different standards.

The regular aluminium profiles have some defects that we can not overcome, especially for the surface of these products, such as warping, deformation, black lines, protrusions, and white lines. Even though the high level designers or some experienced workers can use the expertise and very accurate model to make the products being better, and looks like okay, these regular aluminium profiles can not be totally decrease these inconspicuous flaws. In the standard, we can say the visual range of 40-50CM to distinguish defects are reasonable. The products is allowed to carry out the inspection of defects.

Although regular aluminum profiles have many advantages, they also have some drawbacks: The aluminum without oxidation treatment is prone to rusting, leading to a decrease in performance. Also, it cannot compare with iron products in strength. The resistance of the surface oxide layer can not catch up with that of the electroplated layer, and it is easy to get scratches. The cost is still high, that is about 3-4 times cost higher than that of iron products.

Aluminium extrusion profiles are more complex

However, aluminium extrusion profiles change the visible problems. Compared with the regular ones, the machines and the processing methods are more specific. First of all, we will put the raw materials together, that are aluminum and alloy materials after melting these materials in a big equipment. The procedure can decrease the aluminium defects, and make new elements with higher quality. Then, you will have a model to put the metal liquid in, and be shaped in various directions, such as toys, tools or some convenient equip-mental connections. After the above processing, you can get high hardness and strength materials with many different shapes. It is called as aluminium extrusion profiles. Of course, to be a great issue meeting the criteria needs more steps. Not only molding with special shapes, but also rough polishing to remove mold residue and excellence polishing.

Moreover, the quality of aluminium extrusion profiles come from the molding. It does mean we need a high-qualified mold equipment, a expertise designer, a great manufacturer. They should cooperate before the aluminium pouring into the mold. If you find out the aluminium extrusion profiles are not up to the standards, you can not reproduce them again. That is cost wasted, whatever to customers or manufactures and designers.

Pick up a great aluminium extrusion profiles manufacturers

As I mentioned before, a great aluminium extrusion profiles manufacturer is important during the procedure of aluminium extrusion. How to pick up a great one should be followed as below.

Compare with the feedback from the different customers or designers. Feedback is more important than the advertisements. The manufacturers usually talked a lot in advertisement, but less customer or designers supported their points. The manufacturers will not be in your purchasing list. Their workers and molds, even machines may not be in high quality. Give up them, ignore beautiful advertisement, focus on the feedback from internet or your dealers.

To investigate in local factory fields is another way to delete the unqualified manufacturers. For example, Hugh Aluminum is located in Nanjing Industrial Park, Dasha Town, Zhao Qing City, Guangdong Province, China. They currently have 600-1800 tons extrusion Line, 5000m²anodized production line and 2000m² powder coating production line. The number of employees are more than 200. The location area is around 25000 m². You may not have the clear feeling about these information, but you can go directly to see if they are correct. A factory with annual output around 20000 tons can easily be distinguished in the field. Hugh Aluminum is open for any designers, and potential customers.

Aluminium extrusion profiles: customised solutions

The manufacturer that owns the customized service is less, but Hugh aluminum did it. Customize means you have to pay more attention on the unique requirements. Since many factories of aluminium extrusion profiles prefer to regular aluminium profiles, unique requirements means high cost in mold and different standards. A small factory can not hold the high cost and does not want to take responsibilities. It has no perfect after sale service. But, Hugh Aluminum can do anything that customers applied for. They can communicate with customers intimately and they have a individual design group to suggest the customers a suitable way to finish task. They can give customers a good price, a good delivery and a high quality profile.

Conclusion

Aluminium extrusion profiles offer a unique combination of properties that make them ideal for various applications going through different industries. Design, production and using material specifications all show the in-depth overview and value of aluminium extrusion profiles. In recent years, the aluminium extrusion profiles are wide-spread in construction area, and likely to remain a vital component in many sectors. It is a recyclable materials continues to grow and make the entire environment improve positively.

Q&A

- aluminium extrusion profiles are more exquisite than the other aluminium profiles?

Not really. They have different advantages. It relies on the requirements of the projects. Also, it depends on the use range of the stuff. Of course, if we want to get more remarkable products, we will try the extrusion way to finish them. But we still should put the cost on the top. To find the most suitable way to deal with the problems about material is reasonable.

- How about the after- sale service of Hugh Aluminum?

If you find the aluminium extrusion profiles are not fit for your requirements, you can directly phone Hugh Aluminum. They have technical and design groups to co-work with customers to fix the problems. However, their products and design layout usually asked for customers’ agreement before producing. It is rarely to meet the after sale problems.

- How to find the contact information of Hugh Aluminum?

You can search Hugh aluminum. And find the last station called “contact us”, click in and find out all contact information inside. Or you just want to get know about it, you can type down your information in website, and left your phone number or email address. Hugh Aluminum will contact with you as soon as possible.