Best Aluminum For Welding | The Art And Science

Welding aluminum presents unique challenges due to its properties and heat sensitivity. Choosing the right aluminum alloy, however, can greatly simplify your projects and improve your outcomes. Best aluminum for welding – that’s the secret every welder needs to master to achieve strong, durable, and impeccably clean results.

The key to successful aluminum welding lies in understanding the nuances of alloy composition, temper, and welding process. For instance, alloys with a higher magnesium content, such as 5083, are generally more resistant to cracking and easier to weld. Meanwhile, alloys in the T6 temper, while offering superior strength, may be more prone to cracking during the welding process. Additionally, the chosen welding method, whether TIG, MIG, or spot welding, significantly impacts the suitability of different aluminum alloys.

At Hugh Aluminum, we specialize in providing the highest quality aluminum alloys tailored for superior welding performance. This article will delve into the specific characteristics that make certain aluminum types stand out in welding applications. Whether you’re working in a professional workshop or tackling projects in the field, the choice of aluminum can dramatically influence both the effectiveness and efficiency of your efforts.

Why Aluminum Is The Best For Welding

When it comes to welding, aluminum stands out for its impressive strength-to-weight ratio, making it a top choice for industries ranging from aerospace to transportation. If you’re considering materials for your next project, aluminum’s versatility allows for high-quality welding that is both lightweight and durable. This makes it ideal for applications where performance and weight are critical factors.

As you explore aluminum welding, it’s important to recognize how its thermal conductivity and corrosion resistance can benefit your projects. Unlike heavier metals, aluminum can maintain strength without adding significant weight, enhancing the overall efficiency of any build.

The Science Behind Effective Aluminum Welds

Understanding the Metallurgy of Aluminum

Aluminum’s metallurgical characteristics greatly influence its weldability. This lightweight metal is highly malleable and has a lower melting point compared to steel, making it ideal for a variety of welding applications. Understanding the grain structure and how it can be affected by heat is crucial. Aluminum alloys are categorized by series, each with different elemental compositions that affect their behavior when welded. The presence of elements like magnesium, silicon, and copper in these alloys can impact everything from fluidity during welding to the final mechanical properties of the weld.

Aluminum’s crystal structure changes dynamically during the welding process, which can lead to unique challenges such as hot cracking. Familiarity with these metallurgical principles can help you anticipate and mitigate potential problems before they compromise the weld’s integrity.

How Heat Affects Aluminum During Welding

Heat management is critical when welding aluminum due to its high thermal conductivity and specific heat capacity. Aluminum absorbs heat quickly and distributes it widely, which can lead to uneven heating and cooling. This rapid thermal transition can cause significant distortion and residual stresses within the weld and the parent material.

To control these effects, it’s essential to use controlled heat input methods and to understand the thermal profiles that occur during welding. Techniques such as pulse welding can be particularly effective in managing heat input, minimizing the zone affected by heat, and reducing the risk of defects like porosity and cracking.

Aluminum stands out as a preferred material for a variety of engineering and design projects due to its excellent strength-to-weight ratio. However, welding aluminum requires a deeper comprehension of its specific properties compared to other metals like steel.

How Weldable is Aluminum?

The capacity for welding aluminum varies significantly across its alloy spectrum. While some aluminum alloys are straightforward to weld and deliver reliable results, others are notoriously challenging and may be considered nearly “unweldable” with standard arc welding methods.

Critical Factors for Welding Aluminum

Achieving a successful weld with aluminum hinges on addressing two primary challenges:

Oxide Layer Challenges:

Aluminum naturally forms a protective oxide layer that is corrosion-resistant but problematic for welding. This layer is considerably harder than the aluminum underneath and has a much higher melting point. Improper removal of this oxide layer before welding can introduce contaminants into the weld, potentially leading to weak joints that are susceptible to porosity and cracks.

Managing Thermal Conductivity:

Aluminum’s high thermal conductivity means it heats up and cools down rapidly, posing challenges in heat management during welding. This property requires precise control of heat application to ensure effective weld penetration without overheating and burning through the material, especially in thinner sections.

Optimal Techniques for Effective Aluminum Welding

Proper preparation and technique are key to overcoming the challenges of welding aluminum:

Thorough Surface Preparation: Effective removal of the oxide layer is critical. This involves meticulous cleaning to ensure the surface is free from contaminants that could impair the quality of the weld.

Strategic Heat Management: Adjusting the amount of heat and potentially preheating the aluminum can help manage its propensity to quickly distribute heat. This approach facilitates a strong, consistent weld by ensuring the weld penetrates deeply enough without damaging the material.

Key Properties of Weldable Aluminum Alloys

Aluminum alloys are renowned for their weldability, but not all alloys are created equal. The key properties that make an alloy weldable include its melting point, thermal conductivity, and chemical composition. For example, some aluminum alloys are treated to enhance their strength after welding, while others are designed for better ductility.

When you’re selecting an alloy, consider factors such as crack sensitivity and the alloy’s reaction to heat. These properties will greatly affect your welding process and the quality of your final weld. Understanding these aspects will equip you to choose the best aluminum alloy for your specific needs.

Choosing The Best Aluminum For Welding

When choosing the best aluminum for welding, it’s crucial to understand the unique properties and strengths of different aluminum alloy series. Each series is suited to particular applications based on its elemental makeup and resulting mechanical properties.

Understanding Aluminum Alloy Series:

- 1000 Series: These alloys are the purest forms of aluminum with high electrical conductivity and excellent formability, making them perfect for electrical applications and general welding where high strength is not the primary requirement.

- 2000 and 7000 Series: These alloys are infused with elements like copper and zinc, enhancing their hardness and tensile strength. This makes them suitable for applications requiring high strength, such as aerospace components, where 7075 aluminum is favored for its high strength and fatigue resistance.

- 5000 Series: Known for its good weldability and excellent corrosion resistance, this series strikes a balance, making it ideal for projects exposed to corrosive environments. It’s commonly used in marine and automotive applications where durability and resistance to corrosion are necessary.

The Weldability of Different Alloy Series

| Alloy Series | Primary Elements | Weldability Characteristics |

|---|---|---|

| 1000 Series Aluminum | Nearly pure aluminum | Excellent weldability due to low melting point and high corrosion resistance. |

| 2000 Series Aluminum | Aluminum with copper | Challenging to weld; prone to cracking and reduced ductility. Special welding techniques needed. |

| 6000 Series Aluminum | Aluminum with magnesium and silicon | Good weldability; popular in various applications due to a balance of strength and workability. |

| 7000 Series Aluminum | Aluminum with zinc | Generally difficult to weld; tends to crack and weaken unless specific precautions are taken. |

| Low-Carbon Steels (e.g., ASTM A36) | Low carbon content | Easy to weld; minimal issues with cracking or hardening, making it suitable for structural applications. |

| High-Carbon Steels | High carbon content | Difficult to weld; prone to hardening and cracking, requiring careful heat management and post-weld treatment. |

| Austenitic Stainless Steels | Nickel and chromium | Generally good weldability; less prone to cracking compared to other stainless steels. |

| Ferritic/Martensitic Stainless Steel | Chromium, lower nickel | More challenging to weld; more likely to suffer from heat-affected zone corrosion and brittleness. |

The weldability of different alloy series varies significantly based on their composition and microstructure. For instance, aluminum alloys are categorized into series such as 1000, 2000, 7000 and 6000, each exhibiting unique welding characteristics. The 1000 series, being nearly pure aluminum, demonstrates excellent weldability due to its low melting point and high corrosion resistance. In contrast, the 2000 series, which contains copper, may present challenges during welding due to its susceptibility to cracking and reduced ductility. This necessitates careful selection of welding techniques and filler materials to ensure a sound joint.

Similarly, steel alloys also exhibit varying weldability based on their carbon content and alloying elements. Low-carbon steels, such as those in the

ASTM A36 range, are generally easy to weld, while high-carbon steels can be more challenging due to their tendency to harden and crack during the welding process. The nickel and chromium content in stainless steels can further influence weldability, with austenitic grades typically offering better results compared to ferritic or martensitic grad

Recommended Alloys for Different Welding Projects

Structural Applications: For projects requiring robust structural integrity, 6061 aluminum is often recommended due to its superior strength and good weldability, making it a staple in constructions and industrial fabrications.

Corrosion-Resistant Needs: In environments where corrosion resistance is crucial, such as in automotive bodies and marine hardware, 5052 aluminum is typically chosen for its excellent resistance to corrosion and overall strength.

Best Aluminium Alloys For Welding and Their Applications

3003 Aluminum: A Versatile Choice

3003 aluminum is one of the most widely used aluminum alloys in the industry due to its exceptional formability, weldability, and moderate strength. It’s commonly employed in the manufacture of heat exchangers, cooking utensils, chemical equipment, and sheet metal work. This alloy’s adaptability makes it suitable for fuel tanks, roofing sheets, and other general fabrication projects that require a soft alloy with good workability

5052 Aluminum: For Strength and Corrosion Resistance

5052 aluminum is renowned for its excellent corrosion resistance, high fatigue strength, and good weldability. This alloy is commonly used in marine environments, automotive fuel tanks, and pressure vessels. Its moderate strength and formability make it ideal for applications requiring complex shapes and deep drawing, such as parts for the aerospace and automotive industries. The adaptability of 5052 aluminum also extends to general fabrication projects, where a balance of strength and workability is essential.

6061 Aluminum: A High-Strength Option

6061 aluminum is one of the most versatile aluminum alloys, known for its good mechanical properties, excellent corrosion resistance, and weldability. This alloy is frequently utilized in structural applications, including construction, automotive parts, and aerospace components. Its strength-to-weight ratio makes it suitable for manufacturing extrusions, plates, and sheets. 6061 aluminum’s ability to be heat-treated enhances its strength, making it a preferred choice for various fabrication projects that require reliable performance.

7075 Aluminum: For Extreme Applications

7075 aluminum is recognized for its high strength and resistance to stress corrosion cracking, making it a popular choice in aerospace applications. This alloy exhibits exceptional mechanical properties and is often used for aircraft structures, military vehicles, and high-performance sporting goods. While it has lower workability compared to other alloys, 7075 aluminum can be machined and formed into complex shapes, making it suitable for specialized fabrication projects where strength is paramount. Its lightweight nature combined with durability makes it ideal for applications demanding high performance under extreme conditions.

Additional Notable Alloys like 1100 and 2219 Aluminum

1100 aluminum is a commercially pure alloy known for its excellent corrosion resistance, high conductivity, and good workability, making it suitable for cooking utensils, heat exchangers, and decorative items. In contrast, 2219 aluminum is a heat-treatable alloy recognized for its high strength and toughness, particularly at elevated temperatures, commonly used in aerospace applications. While 2219 has lower workability, its good weldability and resistance to stress corrosion cracking make it ideal for critical structural applications where high performance is essential.

Preparing Aluminum for Welding

Cleaning and Surface Preparation

Proper preparation of aluminum before welding is crucial to achieving a high-quality weld. As you get ready to weld, cleaning the aluminum surfaces thoroughly is the first step. This process involves removing any contaminants such as oil, dirt, or oxide film. Use a stainless steel brush dedicated for use on aluminum to avoid cross-contamination which could introduce impurities into the weld.

Once brushed, wiping the surface with a clean, solvent-soaked rag can help remove any residual particles or oils. It’s important that the aluminum is completely dry before you begin welding to ensure the best possible results. This preparation not only helps in creating stronger welds but also reduces the likelihood of weld defects.

Using a Filler Metal

Choosing the right filler metal is essential when welding aluminum because it must closely match the properties of the base metal. The most commonly used filler metals for aluminum are 4043 and 5356 alloys. You should select a filler metal that offers good weldability and matches the strength and corrosion resistance of the aluminum alloy you are welding.

When selecting a filler, consider the alloy’s composition and the conditions it will be subjected to in its final application. For example, 4043 is generally good for welding 6000 series alloys for service temperatures below 150°F, while 5356 is preferred for higher strength welds and marine environments.

Equipment and Tools for Welding Aluminum

Must-Have Tools for Professional Aluminum Welders

Successful aluminum welding requires specific tools that cater to its unique properties. Apart from a reliable welding machine suitable for aluminum (such as MIG or TIG), you will need:

- A spool gun or a push-pull feeder for MIG welding to handle aluminum wire without causing tangles or jams.

- Tungsten electrodes for TIG welding, preferably with a composition that stabilizes the arc and minimizes contamination.

- Cleaning brushes made from stainless steel, dedicated exclusively to aluminum to avoid cross-contamination.

- Heat sinks to manage the heat distribution and prevent warping of the material.

These tools are essential for maintaining the quality and integrity of aluminum welds, from preparation through to the final weld.

Innovations in Welding Equipment for Aluminum

The welding industry continually innovates, particularly with aluminum welding equipment. Newer technologies include advanced AC TIG machines that offer adjustable waveforms to better control the heat input and optimize the arc characteristics for different thicknesses and compositions of aluminum. Moreover, robotic welding systems and advanced software controls are becoming increasingly common, providing precision and repeatability that are especially beneficial in high-volume or critical-application scenarios.

Welding Techniques and Tips

Gas Tungsten Arc Welding (GTAW) GTAW

Gas Tungsten Arc Welding (GTAW) GTAW, or TIG welding, is a popular method for welding aluminum due to its ability to produce high-quality, clean welds. When welding aluminum, using AC current is essential as it helps clean the oxide layer during the welding process. A pure tungsten electrode or one alloyed with zirconium or thorium will give you a stable arc and better control.

Keep the torch steady, and use a filler rod that matches the base metal. The key to successful GTAW is maintaining a short arc length, which provides better heat control and reduces the risk of burning through the aluminum.

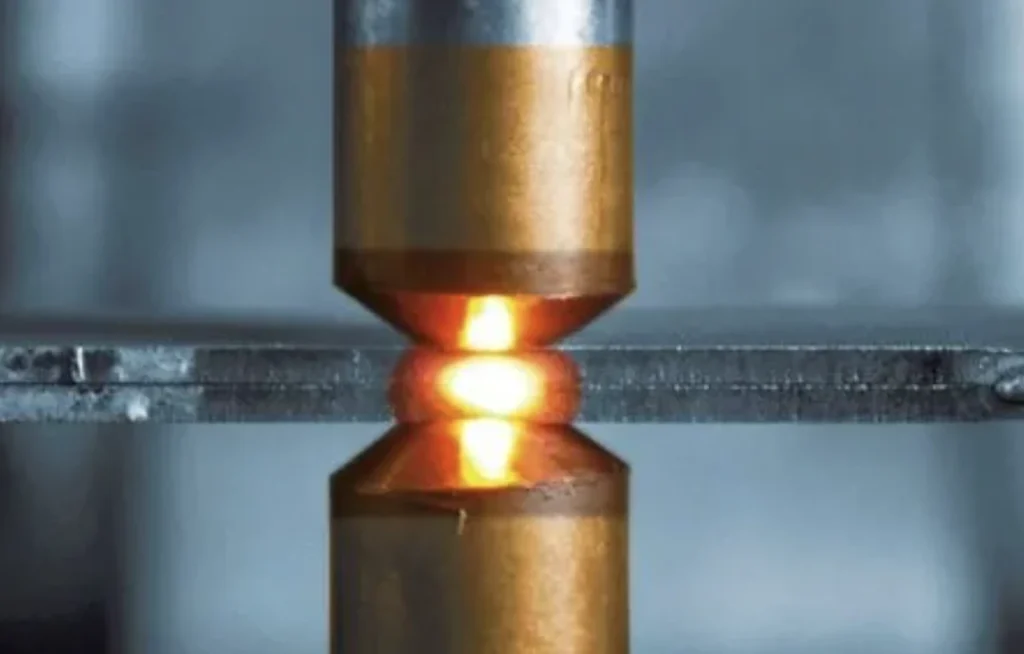

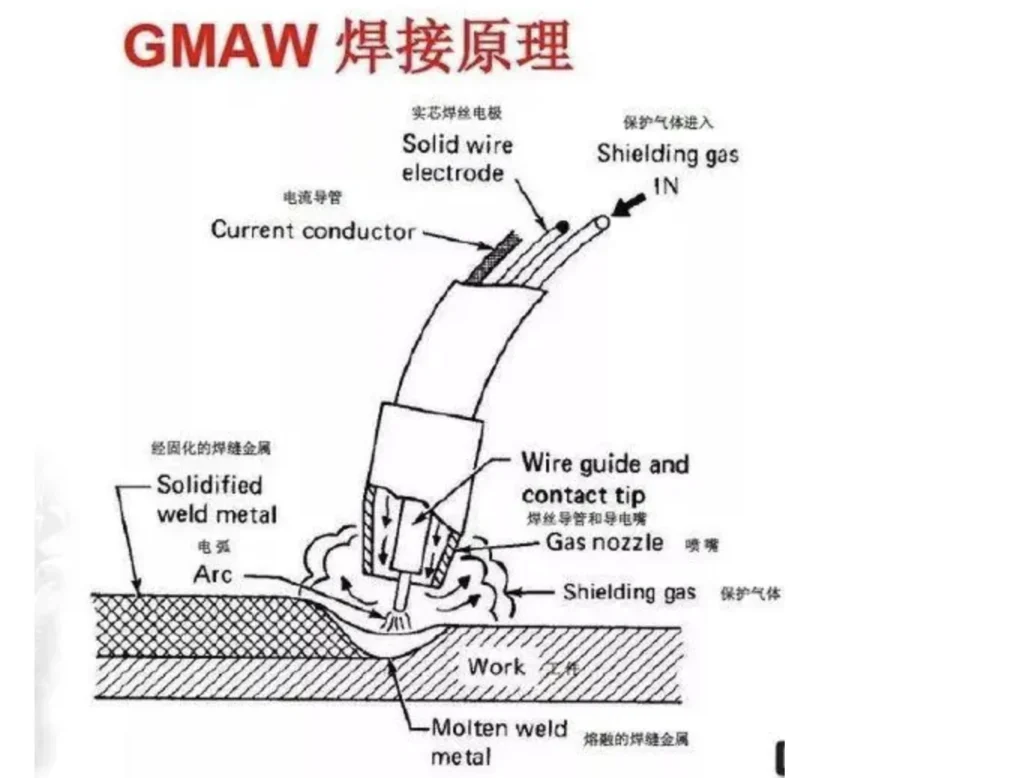

Gas Metal Arc Welding (GMAW) GMAW

Gas Metal Arc Welding (GMAW) GMAW, or MIG welding, is another effective method for welding aluminum. It’s faster than TIG welding and suitable for thicker sections. When using GMAW, it’s important to use a push technique with the gun to ensure better gas coverage and reduce porosity.

Using a spool gun or a push-pull gun can help avoid issues with feeding the soft aluminum wire. Additionally, selecting the right type of wire and shielding gas, typically argon or an argon-helium mixture, can significantly affect the quality of your weld.

Tungsten Inert Gas (TIG) Welding

TIG welding is essentially the same technique as GTAW, often referred to interchangeably. This process allows for greater precision and control, which makes it ideal for thin or highly aesthetic applications. It is particularly beneficial when you require a visually appealing weld or when working on projects that demand precision.

Shielded Metal Arc Welding (SMAW)

Shielded Metal Arc Welding (SMAW) SMAW, or stick welding, is less common for aluminum due to the difficulty of feeding aluminum electrodes and the lower quality of weld it produces compared to GTAW or GMAW. However, it can be useful in outdoor conditions or for quick repairs where equipment simplicity is an advantage.

Tips for Successful Aluminum Welding

When welding aluminum, always ensure your equipment is set up correctly and that you’re using the right parameters for the job. Preheat thicker pieces to avoid cracking, but be careful not to overheat, as aluminum conducts heat quickly. Always allow the piece to cool slowly after welding to avoid stress and distortion.

Remember, practice is key to mastering aluminum welding. Each type of welding has its nuances, so taking the time to learn and apply these techniques will ensure that you can tackle any welding project with confidence.

Common Challenges in Aluminum Welding and How to Overcome Them

Dealing with Aluminum’s High Thermal Conductivity

The high thermal conductivity of aluminum poses a significant challenge, as it leads to faster heat dissipation. This can be managed by preheating the aluminum in thicker sections to reduce the temperature gradient during welding and using techniques that allow for faster travel speeds and higher heat inputs without compromising the weld quality.

Strategies for Minimizing Warping and Cracking

Warping and cracking can be mitigated by employing a proper joint design and fit-up, ensuring the base material and filler metals are compatible, and controlling the welding speed and direction. Techniques such as using intermittent welding (stitch welding), back stepping, and employing post-weld heat treatments can also be highly effective.

Quality Control and Inspection

Visual Inspection

Visual inspection remains a fundamental and first step in quality control for welding. It involves checking for cracks, undercuts, misalignment, incomplete fusion, and other surface defects. This step often requires minimal equipment but a keen eye for detail to spot issues that could lead to weld failure.

Non-Destructive Testing (NDT)

For deeper analysis, non-destructive testing methods such as ultrasonic testing, radiography, and eddy current inspections are used. These techniques allow for the detection of subsurface and internal defects without damaging the component. NDT is essential for critical applications where the integrity of the weld could significantly affect safety and functionality.

Future Trends in Aluminum Welding

Advances in Aluminum Alloy Formulations

The aluminum industry is constantly evolving with new alloy formulations designed to meet the changing demands of technology and engineering. Researchers are developing alloys with improved strength, higher thermal conductivity, and better weldability. These advancements not only enhance the performance of aluminum in traditional sectors like aerospace and automotive but also open new applications in sectors such as renewable energy and lightweight structures. As these new alloys become more mainstream, they promise to revolutionize aluminum welding techniques, making welding faster, safer, and more robust.

The Growing Importance of Eco-Friendly Welding Practices

Sustainability is becoming increasingly crucial in all aspects of manufacturing, including welding. The aluminum welding industry is focusing on reducing its environmental impact through several strategies:

- Using advanced welding technologies that reduce power consumption and material waste.

- Developing greener filler materials that emit fewer fumes and are less harmful to welders and the environment.

- Recycling aluminum scraps from welding and fabrication to minimize waste and decrease the demand for primary aluminum, which is more energy-intensive to produce.

These eco-friendly practices not only help companies adhere to stricter environmental regulations but also appeal to a consumer base that values sustainability.

Hugh Aluminum: Your Trusted Best Aluminum For Welding

Why Choose Hugh Aluminum

Choosing Hugh Aluminum means partnering with a leader in the aluminum industry known for reliability and excellence. With over 15 years of experience, we provide high-quality aluminum products tailored to meet your specific welding needs. Our expertise in aluminum metallurgy allows us to offer insights and support that go beyond just supplying materials—we empower your projects to achieve higher standards of strength and precision.

Our Commitment to Quality and Innovation

At Hugh Aluminum welding factory, our commitment to quality is matched by our drive for innovation. We continuously invest in research and development to refine our alloys and enhance their performance in diverse welding applications. Our rigorous quality control processes ensure that every batch of aluminum we deliver meets stringent industry standards, providing you with a consistent, reliable product every time.

Final Thought

As you consider your options for the best aluminum for welding, it’s important to choose a supplier that not only provides quality materials but also supports your projects with expertise and innovation. At Hugh Aluminum, we pride ourselves on delivering top-tier aluminum solutions tailored to meet the demands of diverse welding applications. Our commitment to sustainability and technological advancement ensures that you are equipped with the best resources to complete your projects efficiently and effectively.

Are you ready to elevate the quality of your welds with superior aluminum? How can we help you achieve your next project goals? We invite you to join our community of satisfied customers and experience the difference that Hugh Aluminum can make in your welding success.

Reach out today, and let’s discuss how we can support your welding needs with the best aluminum for welding. Together, we can achieve outstanding results that stand the test of time.