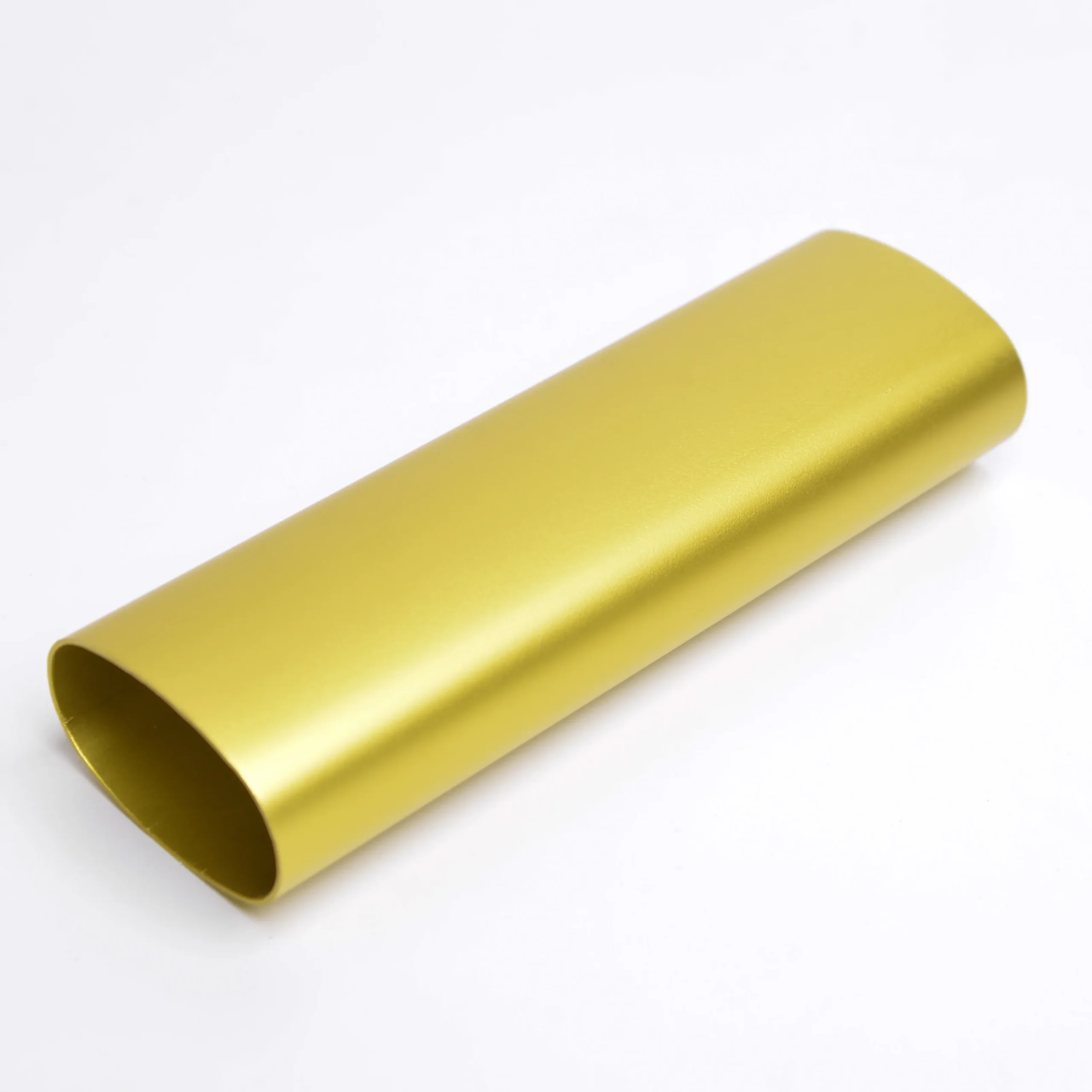

Aluminum Oval Tube

| Product | Aluminum Oval Tube |

| Material | 6063 6061 6082 3003 aluminum alloy |

| The Type and Sizes | 1-6 Meters per piece, or as your inquiry |

| Delivery & Lead time | 21 days after the drawing is confirmed & done payment |

| Length | 1-6 Meter per piece, or as your inquiry |

| Fabrication We offer | Aluminum tube design, Aluminum Extruding, Cutting, Drilling, Welding, CNC machining, Punching, Polishing |

| Aluminum Finishing | Anodizing, Mill finish, Electroplating, Polishing, Powder coating, blasting |

| OEM&ODM | Available |

| Quality Control | ISO 9001 certification, GB/T 5237-2008 |

| Mini Order Quantities | at least 500 kg. Payment methods can be discussed with our sales staff by e-mail. |

Think of a round tube transformed into an oval. That’s our aluminum oval tube—designed for purpose.

This design is revolutionizing aluminum alloy tubing. Its oval cross-section may seem simple, yet it unlocks a world of possibilities.

Why oval? Because sometimes standard shapes don’t cut it. Our oval tube offers advantages that round or square tubes can’t match.

In specific applications, this oval design solves problems efficiently. It’s versatile, tackling challenges where traditional shapes fall short.

Choose the aluminum oval tube for your next project. It offers precision engineering and optimal results.

Aluminum Oval Tube: Engineering Elegance

Nature’s design inspires our engineering. Like an egg’s optimal shape, our aluminum oval tubes represent intelligent structural innovation.

Distinctive Cross-Section

- Packs a punch-in load-bearing capacity

- Outshines traditional round tubes in aesthetics

- Boosts fluid flow efficiency – perfect for aerospace and automotive industries

Bend It Like a Pro

Our oval tubes excel under bending and twisting forces. They withstand external pressures that exceed the capabilities of round tubes.

Aesthetic Engineering

Structural support meets design excellence. Our oval tubes elevate:

- Furniture design

- Architectural facades

- Stair railings

It is precision engineering with visual impact.- sophisticated, strong, and always ready for action.

Space Optimization Mastery

Traditional tubes struggle in confined spaces. Aluminum oval tubes excel where others cannot.

Key Advantages:

- Oval cross-section maximizes spatial efficiency

- Adapts to complex design requirements

- Performs optimally in restricted environments

Fabrication Versatility

Hugh’s oval tubes offer exceptional manufacturing flexibility:

- Extrusion: Precise shaping

- Stretching: Enhanced elongation

- Stamping: Accurate forming

These processes maintain the tubes’ structural integrity while allowing complex designs.

Surface Treatment Excellence

The oval tubes combine performance with aesthetics:

- Anodizing: Enhances surface hardness

- Electrophoretic coating: Provides versatile finish options

These treatments significantly improve corrosion resistance and durability.

Hugh’s oval-shaped tubes offer versatility and strength for diverse design challenges. Consider their advantages for your next project.

Applications of Aluminum Oval Tube

Architecture and Design

Hugh’s oval-shaped tubes shine in architectural applications. They are commonly used for:

- Building facades, curtain wall systems, and window frames

- Stair railings and other exterior decorative elements

Their aesthetic appeal and fabrication flexibility make them ideal for modern architectural designs. Inside, they serve as stylish handrails, ceiling features, room dividers, and furniture frames, adding a contemporary artistic touch.

Aerospace and Transportation

In the aerospace sector, aluminum oval tubes are essential for:

- Aircraft frames, wing structures, and other load-bearing components

Their lightweight yet strong properties reduce drag and enhance aerodynamic performance. In the automotive industry, these tubes are utilized in vehicle frames and supports, particularly where high strength and reduced weight are critical.

Sports Equipment

Aluminum oval tubes are prevalent in sports gear. They are used in:

- Bicycle frames and support structures for various sporting equipment

Their lightweight nature combined with strength meets the demands of high-performance sports gear.

Machinery

In mechanical applications, aluminum oval tubes provide support in:

- Frameworks, columns, and structural components

Thanks to aluminum’s high strength and corrosion resistance, these tubes contribute to the long-term stability of equipment, especially in weight-sensitive designs.

The Standard Size Chart by Hugh Aluminum:

| Length (mm) | Wall Thickness (mm) | R Radius (mm) | Width (Short Axis × Long Axis) |

|---|---|---|---|

| 1000-7000 | 1.5–5.0 | 2.0–4.0 | 20 × 40 |

| 1000-7000 | 1.5–6.0 | 3.0–5.0 | 25 × 50 |

| 1000-7000 | 2.0–5.0 | 3.0–6.0 | 30 × 60 |

| 1000-7000 | 2.0–6.0 | 3.5–6.5 | 35 × 70 |

| 1000-7000 | 2.5–6.5 | 4.0–7.0 | 40 × 80 |

Specifications Notes:

Length: Standard lengths for aluminum oval tubes typically range from 1000mm to 3000mm. However, we offer customization to meet your specific requirements.

Wall Thickness: The wall thickness generally varies from 1.5mm to 6mm, tailored to suit the demands of your application.

R Radius: The corner radius (R radius) of the elliptical tube usually falls between 2mm and 7mm, providing flexibility in design.

Dimensions (Short Axis × Long Axis): The dimensions of the short and long axes define the width of the elliptical tube. Common sizes range from 20×40mm to 40×80mm, with options for custom sizes available upon request.

Feel free to reach out for any specific needs!

Reviews

There are no reviews yet.