Square vs Round Tubing: Applications, Advantages and More Comparison

Tubing is always a big deal in construction and manufacturing. With the demand growing, different shapes of tubing have come out. But square and round tubing are the most popular. Let’s get into the details of these two types of tubing, their shapes, applications, and advantages.

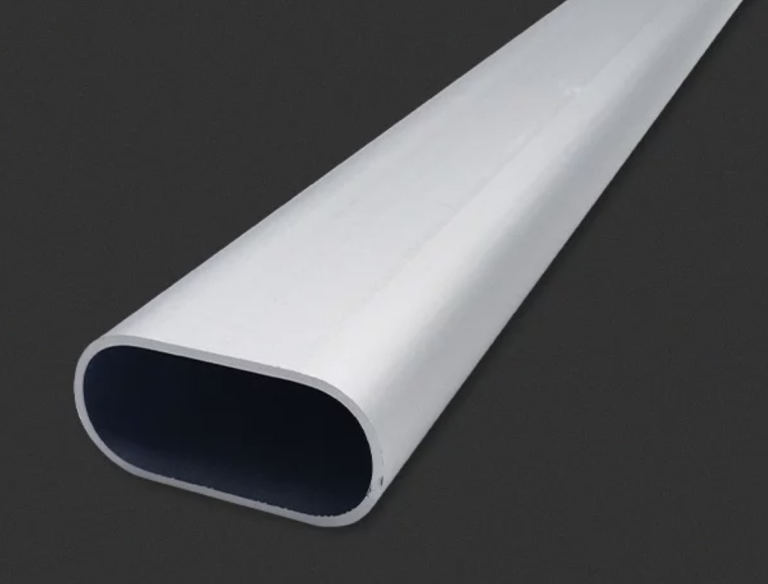

Square tubing has flat surfaces and sharp corners, perfect for structural applications where strength and stability are key. Round tubing has a smooth continuous surface, which is great for applications requiring flexibility and bending resistance.

Compare Square Tubing and Round Tubing

Aluminum extrusion allows for various tubing shapes, including square and round. Both types come from the same process, where a flat piece of aluminum is bent and welded. A tool called a “mandrel” creates a hollow center in round tubing.

Advantages of Round Tubing

Round tubing is easier to extrude and uses less material. This makes it a popular choice for many projects. However, square tubing has specific benefits that can make it the better option in certain situations.

Advantages of Square Tubing

- Cutting: You can cut square tubing easily with standard tools. This saves time on the job site.

- Affixing Hardware: The flat surfaces of square tubing hold various hardware shapes securely. This feature creates stable connections.

- Fitting into Tight Spaces: Square tubing fits into corners and tight areas more effectively than round tubing. Its shape allows it to be positioned snugly against walls or other structures.

- Welding: With accurate measurements, you can weld square tubing closely together. This results in stronger joints and better overall strength.

- Decoration: Square tubing can be customized in different shapes and painted easily. Many customers prefer its clean look for decorative uses.

Making the Right Choice

Before selecting your tubing, think about your specific needs. Measure the diameter of the walls or spaces where you plan to install the tubing. This will help you find the best fit for your project.

Both square and round tubing have their strengths. Understanding these differences will help you choose the right type for your application, leading to successful results every time!

Square Vs Round: What’s the Difference in Strength and Durability?

Round tubing is stronger and more durable than square tubing. Its round shape distributes pressure evenly across its surface so it’s more resilient. When comparing equal weights, round tubing is usually about 20% lighter than square tubing of the same length and thickness. This even pressure distribution makes round tubing more stable and less prone to breaking. Many round tubes can last decades without showing much wear.

Square tubing is strong too but its shape creates different pressure points. The edges are stronger, the flat surfaces are weaker. If the pressure is uneven, square tubing can fail more easily. For example, during twisting operations, square tubing has no flexibility. Imagine trying to twist a round tube in a corner; it moves easily because of its smaller contact area. A square tube gets stuck because of its flat surfaces. You’d have to pull it out completely and reposition it which can reduce its durability over time.

Both have their advantages, but round tubing wins in strength and longevity because of its shape and pressure distribution. If durability is your top priority for your project, go round!

Cutting and Shaping

Square tubing is easier to cut, and round tubing is more flexible and can be bent or shaped. But the shapeability of either depends on size and thickness. Larger OD with thinner walls can be shaped under pressure. Since both are hollow they must withstand ripping or buckling. Square tubing will break under the same stress as round tubing.

Square Tube Malleability

The flat surfaces of square tubing make it easy to cut with powered cutters or handheld hacksaws. You can position square tubing anywhere to cut. For example, you can lay it on the floor or press it against a wall while cutting and keep it stable.

However, the uneven pressure on its four surfaces will cause quick shape changes. So you can make irregular shapes more easily with square tubing.

Round Tube Malleability

Round tubing has even pressure across its surface. No corners and angles to bend and shape smoothly. This minimizes distortion and maintains strength after reshaping. But cutting round tubing requires more effort. You need a stabilizer to hold it in place while cutting and additional tools.

In short, both square and round tubing have their strengths in cutting and shaping. Square tubing is easy to cut, and round tubing is flexible and can be shaped smoothly. Choose wisely! Also, only focus on the round tube surface, it is impossible to be made into other irregular shapes.

What is the Difference in Welding?

Square tubing provides clear benefits for welding. Its flat surfaces allow you to work along four edges easily. You can measure the outer diameter (OD) or thickness accurately for each side, which simplifies the welding process.

In contrast, welding round tubing requires more focus. You must pay attention to the curved surface and ensure sizes match closely. A small error in measuring the OD or thickness can lead to issues during welding, especially with complex joints.

When using round tubing, precision is essential. The curved shape can make it harder to achieve a perfect fit, which may weaken the weld.

Square tubing is often the better choice for straightforward welding tasks. Its shape allows for easier handling and accurate measurements, resulting in strong welds. While round tubing offers flexibility, it demands more care and precision during welding. Choose based on your project needs.

Applications and Use Cases Comparison

Square tubing and round tubing have different facts of application.

Use Cases of Round Tubing

Round tubing is commonly used for transporting liquids and gases. Its shape allows it to contain these substances without leaving any residue inside. This makes round tubing a great choice for applications where pressure may change over time or where different materials are involved.

- Fluid Transport: Round tubes are ideal for delivering liquids and gases in plumbing and industrial settings.

- Strength and Durability: Round tubing can handle significant pressure, making it suitable for installation under floors or roads without risk of deformation.

- Lightweight Design: The lighter weight of round tubing can lower costs, making it an economical option for many projects.

- User-Friendly Handling: Round tubes are easy to grip, reducing the risk of injury when handling finished products.

Use Cases of Square Tubing

Square tubing excels in applications that require stability and ease of assembly. Its flat surfaces make it easier to work with in various construction and manufacturing tasks.

- Welding Applications: Square tubing is perfect for projects that involve multiple welds. Its shape allows for strong connections at corners and joints.

- Drilling and Attaching Hardware: The flat surfaces of square tubing make it easy to drill holes for attaching hardware or other components.

- Tight Spaces: Square tubing fits well in confined areas, such as corners where right-angle bends are needed.

- Aesthetic Designs: Square tubing can be customized to fit specific design needs, allowing for creative solutions in architecture and decor.

Round and square tubing each have distinct advantages based on their shapes. Round tubing is ideal for fluid transport and applications requiring strength, while square tubing excels in welding and structural projects. Choose the right type based on your specific needs!

Final Thoughts

Square tubing is good for many things, structural and decorative. Round tubing is strong and flexible for specific tasks.

To choose the right tubing, think about what you need and the exact dimensions. It’s also important to find a reliable supplier. Talking to a supplier can be very helpful. A good company will have good products, custom designs, and good after-sales support.