The Ultimate Guide to Aluminum Extrusions: Properties, Types, and More

Aluminum extrusions might sound like a fancy industrial term, but they are more ubiquitous than you might think. From the frames of your windows to the sleek designs of your smartphones, aluminum extrusions are everywhere.

This article will guide you through everything you need to know about aluminum extrusions in a simple, conversational tone.

What Is Aluminum Extrusion?

So, what are aluminum extrusions? Imagine squeezing toothpaste out of a tube. The toothpaste takes the shape of the tube’s nozzle, right? Aluminum extrusions work similarly.

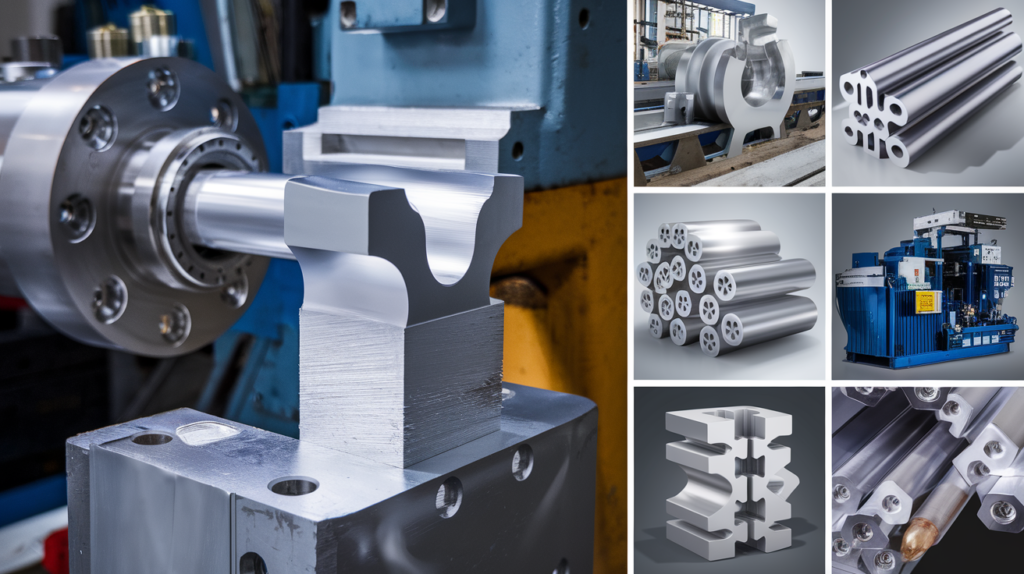

In this process, a die shapes the aluminum alloy, producing a continuous piece of aluminum with a specific cross-sectional profile. This technique allows for the creation of a wide variety of shapes and designs.

The extrusion process allows us to create complex profiles ideal for various applications, from building frameworks to intricate machine components.

End products can be solid, semi-hollow, or hollow, and they offer an excellent strength-to-weight ratio, making them widely used.

Related: What are the aluminum profiles and What is extruded aluminum

Why Aluminum? The Incredible Properties of Aluminum

Before diving into the nitty-gritty, let’s understand why aluminum is the preferred choice. Aluminum boasts of unique properties that make it stand out.

Lightweight Yet Sturdy

Aluminum is incredibly light yet surprisingly strong. A perfect analogy would be comparing it to feathers that can support bricks. Its strength-to-weight ratio is remarkable, making it a top choice for many engineering applications.

Corrosion Resistance

Imagine your car falling apart because of rust. Not cool, right? Lucky for us, aluminum naturally forms a protective oxide layer, making it resistant to corrosion and perfect for use in environments that would eat away at other metals.

With these attributes, it’s no wonder aluminum finds extensive applications in numerous industries.

The Types of Aluminum Extrusions

Aluminum extrusions come in a myriad of shapes and forms. For simplicity, let’s categorize them into standard profiles and complex profiles.

Standard Profiles

Aluminum Angles

These L-shaped profiles come with legs forming a right angle, and serve as ideal framing, braces, and structural support because of their strength and lightweight properties.

Aluminum Beams

Similar to traditional beams, constructors use aluminum beams for horizontal support in construction. They are much lighter than steel beams, making them easier to install and ideal for architectural applications.

Aluminum Channels

These U-shaped profiles provide structural support, framing, and guidance in machinery and vehicle construction. They offer excellent strength and corrosion resistance.

Aluminum Tubes

Aluminum tubes, and cylindrical profiles, serve many applications from scaffolding to automotive parts. They come in various diameters and wall thicknesses.

Complex Profiles

Custom Profiles

Custom profiles are tailored to meet specific needs and applications. They often include intricate shapes, such as screw tracks, handrails, and transition strips.

Heatsinks

Heatsinks are specialized extrusions designed to dissipate heat in electronic devices. Their complex fin structures maximize surface area, enhancing heat transfer.

Related: Aluminum Heatsink Extrusions and Round Aluminum Heatsink

Architectural Profiles

These profiles are used in building facades, window frames, and decorative elements. They combine functionality with aesthetic appeal, adding value to architectural designs.

Specialized Aluminum Extrusions

Aluminum Profiles for Transportation

Transportation applications demand lightweight yet durable materials. Aluminum extrusions are used in railcars, automobiles, and aerospace components.

Marine Grade Aluminum Extrusions

Marine environments require corrosion-resistant materials. Marine-grade aluminum extrusions are perfect for shipbuilding, offering longevity and robustness.

Aluminum Extrusion Dimensions

Engineering demands precision. Even a millimeter off can spell disaster. That’s why precision in aluminum extrusion isn’t just important – it’s essential.

Selecting the correct dimension isn’t just about fitting pieces together. It’s about ensuring structural integrity and function.

Standard Dimensions

A standard dimension for T-slot aluminum extrusion might look something like this: 20x20mm, 30x30mm, and so forth. Increasing these dimensions opens up a world of possibilities.

Custom Sizes

Need something unique? No worries. Customized sizes can be made to fit exact specifications, ensuring no project is left incomplete.

How Strong is Aluminum Extrusion?

Aluminum extrusion is strong enough to support towering skyscrapers, intricate machinery, and complex structural systems – all while being incredibly lightweight and versatile. Its unique properties and the advancements in extrusion technology make it a go-to material for both engineers and designers.

Tensile Strength

Tensile strength refers to the maximum stress a material can withstand while being stretched or pulled before breaking. This value varies considerably for aluminum depending on the alloy used, ranging from 10,000 to 70,000 psi.

Yield Strength

Yield strength is the point at which a material begins to deform permanently. Aluminum alloys typically have a yield strength between 20,000 and 35,000 psi.

More reading: How Strong is Aluminum Extrusion

Common Aluminum Grades and Their Strengths

Grade 6063-T6

This alloy is like the Swiss Army knife of aluminum. It’s super versatile, offering a tensile strength of 35,000 psi and a yield strength of 31,000 psi. Excellent for intricate shapes!

Grade 6061-T6

Known as aircraft-grade aluminum, 6061-T6 provides a tensile strength of 45,000 psi and yield strength of 40,000 psi. It’s the go-to for applications requiring robust strength and durability.

Grade 7075-T6

Picture Hercules in aluminum form. This alloy can handle up to 83,000 psi tensile and 73,000 psi yield strength. High-stress areas and high-performance sectors like aerospace often use it.

Grade 6005-T5

Similar to 6063 but a tad sturdier, this alloy provides a tensile strength of 37,700 psi and a yield strength of 34,800 psi. Ideal for robust structural projects.

Related: How strong is 2020 aluminum extrusion

Common Aluminum Extruded Shapes

At Superior Metal Shapes, the possibilities are endless. Here are some of the most common extruded shapes we produce:

- I-beams

- H-shapes

- Hollow shapes

- L-shapes

- Multi-void hollow shapes

- T-bars

- Tubes (round, serrated, rectangular)

- Zee bars

Each of these shapes serves unique purposes across various applications. Whether you’re designing a lightweight frame or a robust structural component, aluminum extrusions offer unparalleled flexibility.

How are Aluminum Extrusions Made? The Extrusion Process

The extrusion process is a beautiful blend of science and art. It starts with a cylindrical billet of aluminum, heated until it’s pliable but not yet melted.

A hydraulic press drives the billet through a die, and the aluminum emerges shaped like the die’s profile. This process produces long, continuous sections that can be cut to length later.

Designing the Die: The Blueprint of Extrusions

The journey of an aluminum extrusion starts with designing the die. This die is like a mold that the aluminum will be shaped through. Engineers work meticulously to create the tooling and die, considering the final shape, size, and material specifications.

Heating the Billet: Getting Ready for Action

Next up is the aluminum billet—a log of raw aluminum. It’s heated to make it soft and malleable. Think of it as warming up your Play-Doh before sculpting your masterpiece.

Pushing Through: The Extrusion Begins

Once the billet is soft enough, it’s time for the big squeeze! The extrusion press applies immense pressure to the heated billet, pushing the aluminum through the die. On the other side, it emerges as a long, continuous shape—an aluminum extrusion!

Turning Heat to Strength: Cooling and Hardening

After extrusion, you need to cool and harden the aluminum. This involves stretching it to remove any twists and then cutting it to the desired lengths. The final step involves treating the aluminum with heat in age ovens, a process that speeds up aging and enhances the metal’s strength.

Related: How are Aluminum Decks Made?

How to Cut Aluminum Extrusion?

You can cut aluminum extrusion using various tools and methods, depending on the precision and finish required. Here are some common methods.

Cutting Aluminum Extrusion at Home (DIY Guide)

- Measure and Mark: Use a square and pencil to mark the cut line.

- Secure the Material: Clamp the aluminum securely to avoid movement.

- Initial Cut: Utilize a hacksaw or a jigsaw with a metal-cutting blade. Maintain a steady pace.

- Guide the Blade: For a straight cut, use a miter box or a square.

- Finishing Touches: Use a file or sandpaper to remove rough edges.

Common Mistakes to Avoid

- Wrong Blade: Leads to breakage and potential injury.

- Insecure Clamping: This can result in inaccurate cuts.

- Cutting Too Quickly: Causes overheating and blade damage.

If you have access to professional tools, you can achieve more accurate results.

Professional Aluminum Extrusion Cutting

- Set Up Saw: Use a miter or circular saw with a blade suited for non-ferrous metals.

- Secure the Aluminum: Utilize clamps or a vise.

- Wear Protective Gear: Safety goggles, face shield, gloves.

- Apply Cutting Oil: Prevents overheating and extends blade life.

- Make the Cut: Align the saw blade with the marked line and maintain a steady pace.

Advantages of Professional Method

- Higher Precision: Ideal for intricate designs.

- Efficiency: Faster cutting process.

- Versatility: Suitable for various extrusions.

Safety Precautions and Best Practices

- Always Wear Safety Gear: No exceptions.

- Use Appropriate Blade: Non-ferrous cutting blades.

- Clamp Material: Avoid movement during cutting.

- Apply Lubrication: Prevents blade wear and overheating.

More Reading: How to cut aluminum extrusions

Conclusion

Aluminum extrusion is a remarkable process that offers endless possibilities. From simple rods to complex shapes, this method is a cornerstone in modern manufacturing.

Understanding the extrusion process not only broadens your knowledge but also helps you appreciate the engineering marvels around you.

FAQs

What is the primary benefit of using aluminum extrusion?

Aluminum extrusion allows for the creation of complex, custom shapes with excellent strength-to-weight ratios, making it highly versatile and efficient.

Can aluminum extrusions be recycled?

Absolutely. Aluminum is 100% recyclable, and recycling it saves up to 95% of the energy required to produce primary aluminum.

What industries benefit the most from aluminum extrusions?

While many industries benefit, key sectors include automotive, aerospace, construction, consumer electronics, and renewable energy.

How do advancements in technology impact aluminum extrusion?

Technological advancements, particularly in automation and alloy development, enhance the precision, efficiency, and scope of applications possible through aluminum extrusion.