Aluminum Edge Trim VS Plastic Edge Trim

What is the difference between aluminum edge trims and plastic? This is a question that consumers may want to know.

Let’s explore the differences in more detail today:

1.Material Characteristics

Aluminum edge trim:

Its main material is 6063 aluminum alloy, which has the advantages of light weight, high strength, corrosion resistance and not easy to rust.

Aluminum alloy material makes the decorative strip has high strength and toughness, can maintain stable performance for a long time.

Plastic edge trim:

Its main material is plastic, which has the characteristics of light weight, easy processing, low cost and so on. However, plastic material is easy to deform and aging under high temperature conditions, and not as corrosion-resistant as aluminum alloy.

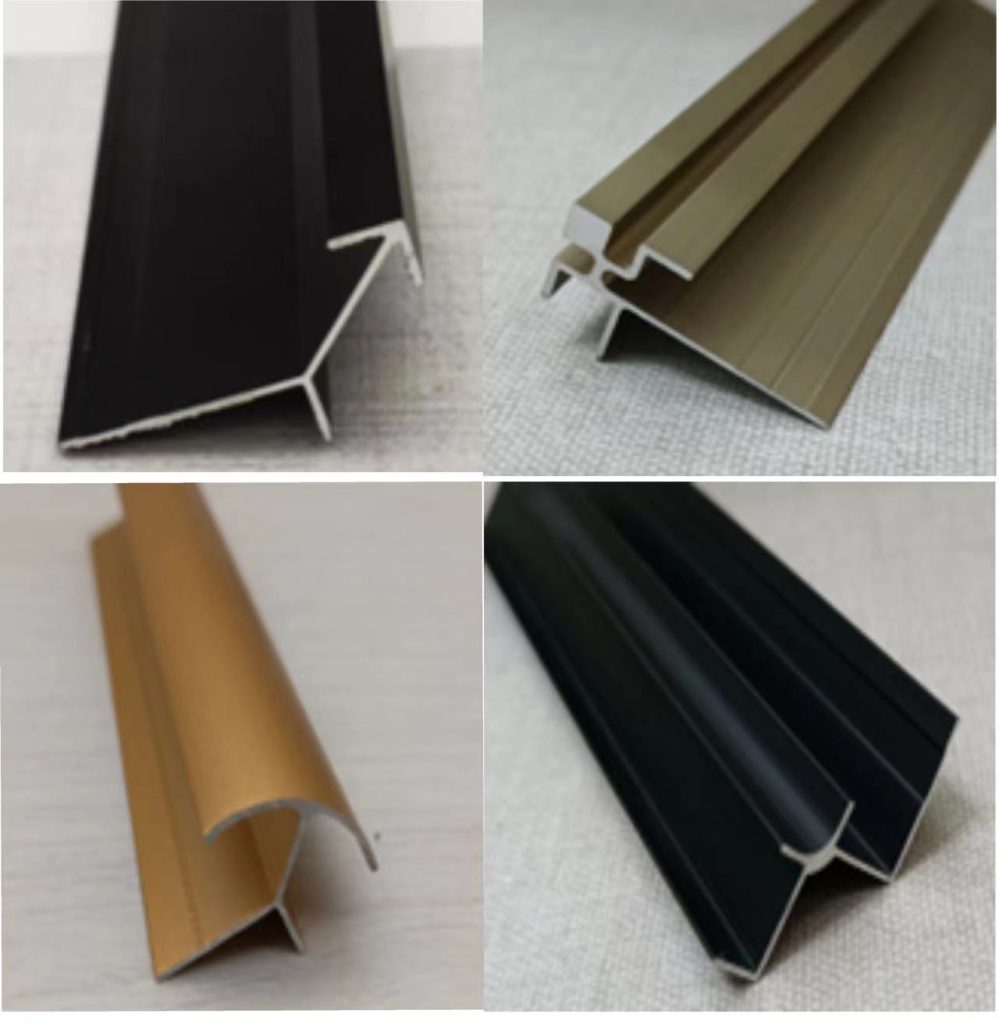

2. Appearance and color

Aluminum edge trim:

It has a smooth appearance, bright color and strong metallic texture. Various color appearance can be obtained through the process of surface treatment. It can be customized to meet the needs of different decorative styles.

Plastic edge trim:

It has a relatively simpler appearance with a single or limited color. This is because the color depth of the plastic cannot be controlled. Although the color is optional, the texture of plastic has a certain gap compared with metal.

3. Performance and Durability

Aluminum edge trims:

It has good fire, moisture and insect resistance. Because of the use of aluminum alloy 6063, it has strong weather resistance. It is able to maintain stable performance in various environments. It is the best choice as a decoration for public places. In addition, it has high strength, is not easy to be deformed or damaged, and has a long service life.

Plastic edge trims:

It has relatively poor fire resistance and is flammable.

It has weak weather resistance and is prone to aging and discoloration when exposed to sunlight for a long time.

Its strength is low, easy to be deformed or damaged, and its service life is relatively short.

4. installation and maintenance:

Aluminum edge decoration strip:

Easy to install, can be fixed in a variety of ways, such as nails, glue, etc.. It has low maintenance cost, only need to carry out routine cleaning and maintenance. The service life can reach more than 15 years.

Plastic edge decorative strip:

It is relatively easy to install, but the fixing methods are more limited. Plastic edge trim is low maintenance. Problems can be replaced directly. However, attention should be paid to avoid aging problems caused by high temperature and direct sunlight.

5. Environmentally friendly

- Aluminum: aluminum alloy material can be recycled and reused, with high environmental protection.

- Plastic: Its material is not easy to degrade, causing a certain burden on the environment. But some new plastic materials such as PVC are also trying to improve environmental performance.

Summarize the above

Aluminum edge trims are better than plastic edge decorative strips in terms of material properties, appearance and color, performance and durability, installation and maintenance, and environmental protection. However, the specific choice needs to be weighed according to actual application scenarios and needs.

Hugh Aluminum is a professional manufacturer of aluminum edge trim. We have 14 years of manufacturing experience and have served over 600 customers and 40 countries.

If you want to know more or buy aluminum edge trim strips in bulk. Please contact us!