Aluminum extrusion alloy: What is the best alloy for your project?

Extrudability of wrought aluminum alloy extrusion

Aluminum extrusion line at the plant:

We can easily make a wide range of shapes through aluminum extrusion and other means. By adding different alloying elements such as magnesium, zinc or copper, “pure” aluminum can be refined into a range of different wrought aluminum/aluminum profile grades.

While the introduction of these alloying elements reduces the excellent formability of aluminum, it also improves the other desirable properties of aluminum. For this reason, aluminum alloys are used in the aluminum extrusion process. It results in improved strength and toughness of aluminum extruded products.

From improved strength to increased corrosion resistance, alloys make the properties of aluminum more suitable for the final product.

The aluminum alloy properties For aluminum extrusion

Choosing the right aluminum extrusion alloy. High strength, lightweight properties and corrosion resistance make aluminum extrusions suitable for a wide range of applications.

From industrial and automotive uses to consumer electronics, aluminum extrusions offer mechanical advantages that make them a versatile choice for your extruded products.

While the general properties of aluminum reflect its versatility, it’s important to note the differences in aluminum alloy grades. Choosing the right grade of aluminum alloy for your extruded product will ensure that your extruded product is designed to meet the requirements of the application.

While the general properties of aluminum reflect its versatility, it is important to note the differences in aluminum alloy grades. Choosing the right grade of aluminum alloy for your extruded product will ensure that your extruded product is designed to meet the requirements of the application.

Aluminum Alloy Properties

Aluminum alloy grades are identified by their series number (from 1xxx series to 7xxx series). The most suitable aluminum grades for extrusion include the alloy series 1xxx 5xxx 6xxx series.

Aluminum Tempering

Extrusion tempering increases strength and makes aluminum a suitable alternative to steel. Common types of extrusion tempering include

T1 – cooling from high temperatures and natural aging

T2 – Cooling from high temperature, cold working, natural aging

T3 – Solution heat treatment, cold working, natural aging

T4 – Solution heat treating and natural aging

T51 – Cooling from High Temperature, Stretching for Stress Relief, Artificial Aging

T6 – Solution Heat Treating and Artificial Aging

T61 – Solution heat treating and artificial aging

Video from Hugh aluminum show aluminum extrusion processing:

Aluminum grades of the 1xxx series are pure aluminum materials with an aluminum content of 99% or more.

The grades are usually indicated by four Arabic numerals, e.g. 1050, 1060, 1100, etc. These aluminum materials have good workability and corrosion resistance.

Its characteristics:

1. high purity: the aluminum content is above 99%, which is the series with the highest aluminum content among aluminum alloys.

2. good machinability: due to its high purity, 1050 aluminum excels in forming and machining processes.

3. excellent corrosion resistance: pure aluminum has inherent good corrosion resistance and is suitable for a wide range of environments.

4. Softer material: The higher the purity, the lower the strength, so 1050 aluminum is relatively soft.

5xxx Series Aluminum extrusion

It represents a series of aluminum alloys with magnesium as the main alloying element. Such as 5052, 5005, 5083, 5A05 and so on.

For example, the characteristics of 5052 aluminum:

1. low density: compared with other series of aluminum alloys, 5xxx series aluminum weighs less under the same area.

2. High tensile strength: it has good tensile strength and is suitable to withstand certain tensile force.

3. High elongation: when the material is subjected to external force, it can produce large plastic deformation without breaking easily.

4. good fatigue strength: in the case of repeated force, can still maintain high strength, not easy to fatigue damage.

5. corrosion resistance: good corrosion resistance, can maintain the stability and durability of the material in a variety of environments.

6xxx series aluminum extrusion

It is an important classification in aluminum alloy. It mainly includes many grades such as 6005, 6060, 6061, 6063, 6082, 6201, 6262, 6463, 6A02 and so on.

1. 6005 aluminum characteristics:

High strength: 6005 aluminum has medium to high strength, which can meet the needs of many applications.

Good corrosion resistance: This series of aluminum has good corrosion resistance and can maintain the stability and durability of the material in many environments.

- Its tensile strength σb(MPa): ≥175

- Conditional yield strength of 6005 aluminum σ0.2(MPa): ≥80

- Elongation of 6005 aluminum δ5(%): ≥15

2. 6061 Aluminum

– Good moldability

– Good weldability, machinability.

– Medium strength and maintains good handling after annealing.

– Specific mechanical properties include ultimate tensile strength, yield strength, and elongation.

- The yield strength of 6061 Aluminum-T6 is 276 MPa.

- The tensile strength of 6061 Aluminum-T6 is 310 MPa

- The elongation of 6061 Aluminum-T6 is 12%, and the Brinell hardness is 95.

Factors to consider when selecting aluminum extrusion alloys

Factors to consider for extrusion design include wall thickness and shape complexity. Complex geometries and thin walls require the use of aluminum alloys such as Alloy 6063. This ensures that the extruded shape is uniform and has low distortion. In addition, we need to consider surface finish requirements and strength requirements.

Why is it important to choose the right grade of aluminum extrusion?

Choosing the right grade of aluminum for your extrusions will save you time and money by avoiding unnecessary design problems. Working with an experienced aluminum extruder can provide you with the necessary guidance and industry knowledge.

Choose Hugh Aluminum to help you find the perfect aluminum extrusion alloy. We are an aluminum extrusion manufacturer located in China.

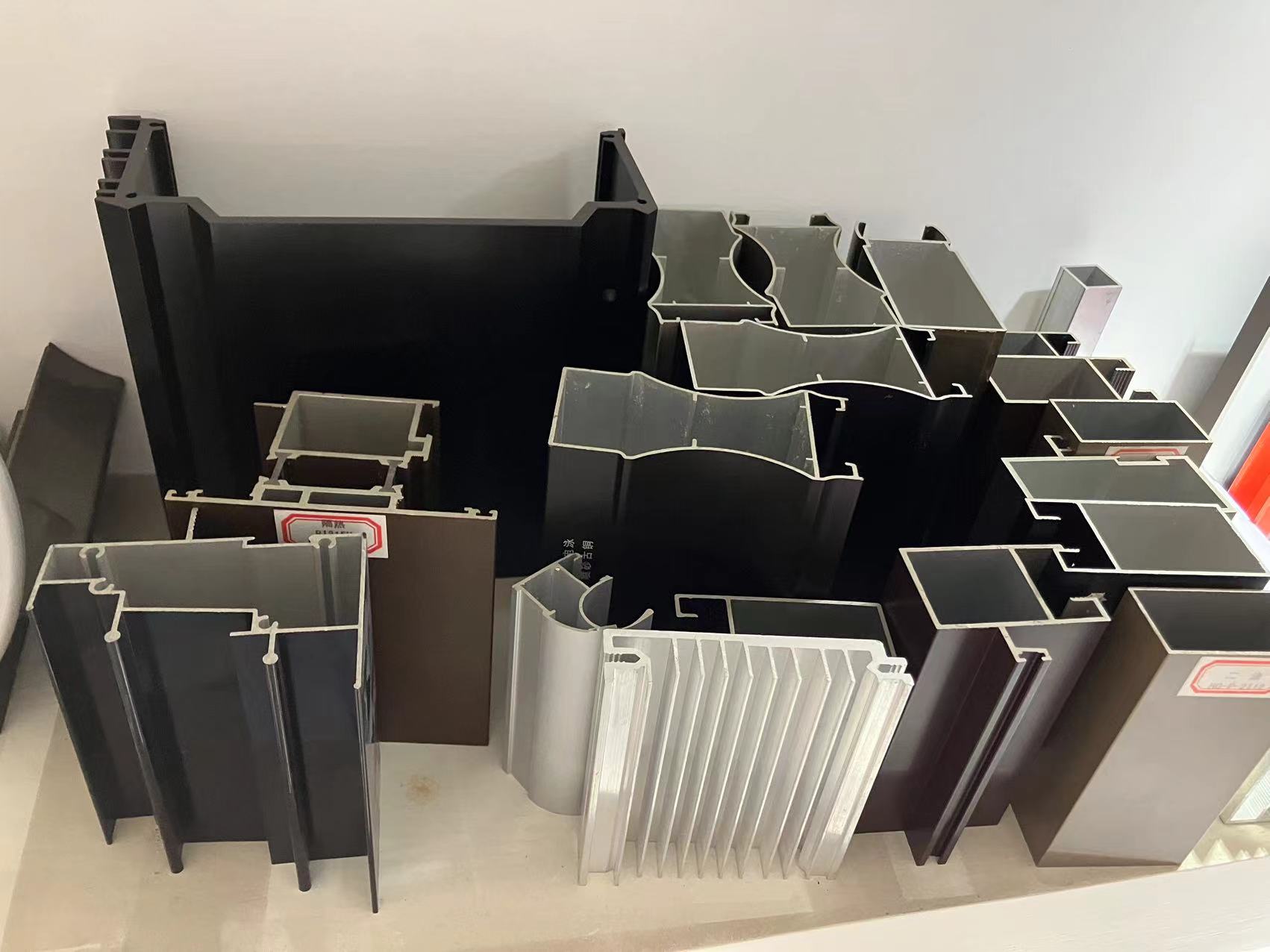

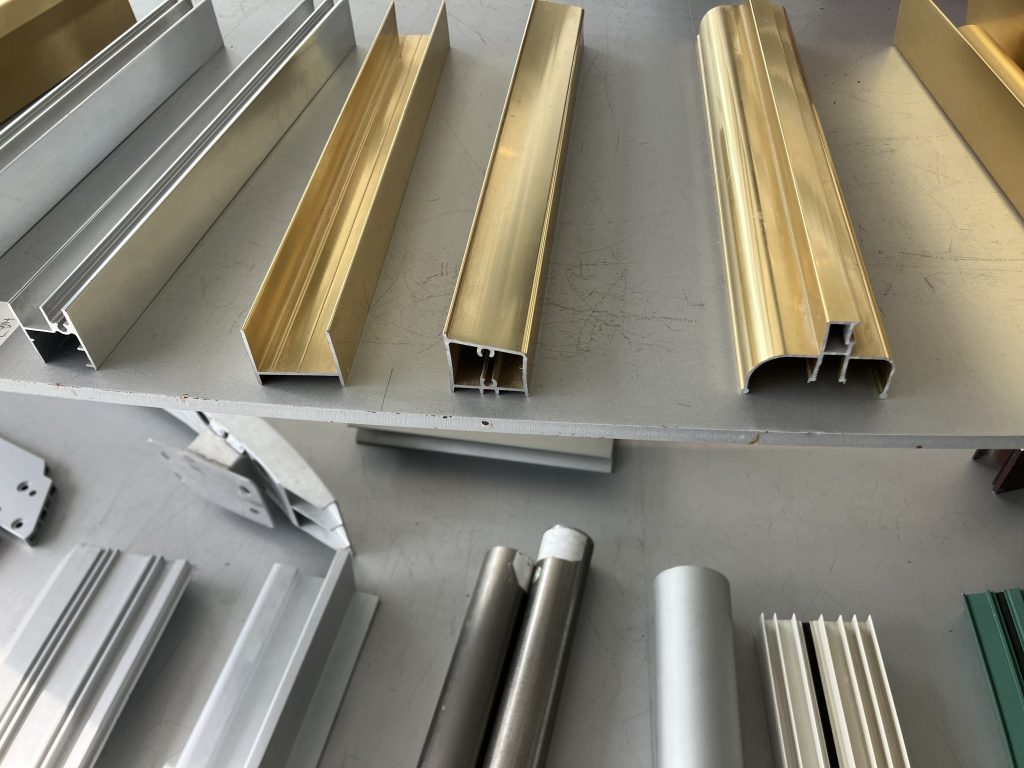

Offering you more than two hundred aluminum extrusion products and OEM services.