Aluminum extrusion Die structure, types and advantages

Brief introduction

It can extrude aluminum into various complex shapes and sizes. Aluminum profile extrusion die is a special die for extruding aluminum alloy profiles. Aluminum profile extrusion die cooperates with extruder, haul-off device, cutting device and die heating and cooling system according to the shape, size, performance and precision requirements of the products.

This kind of die is made of high-strength and high wear-resistant material, which can withstand high temperature and high pressure. During the production process, the aluminum profile extrusion die can ensure the precision and surface finish of the products, making your products more beautiful and durable.

Below video shows Aluminum extrusion production

Structure of aluminum profile extrusion die:

1.Die pad:

It consists of three parts, which are die core, welding chamber and die hole. The die core determines the size and shape of the inner cavity, the welding chamber is where the metal is gathered and welded, and the die hole is the passage for the aluminum bar to enter the profile hole.

2. Mold sleeve:

The die set consists of four parts, namely, shunt hole, shunt bridge, die core and welding chamber. The shunt hole is the channel for aluminum to pass through the profile hole, the width of the shunt bridge and the strength of the die are related to the metal flow, the die core determines the size and shape of the inner cavity, and the welding chamber is the place where the metal is gathered and welded.

Types of aluminum extrusion dies:

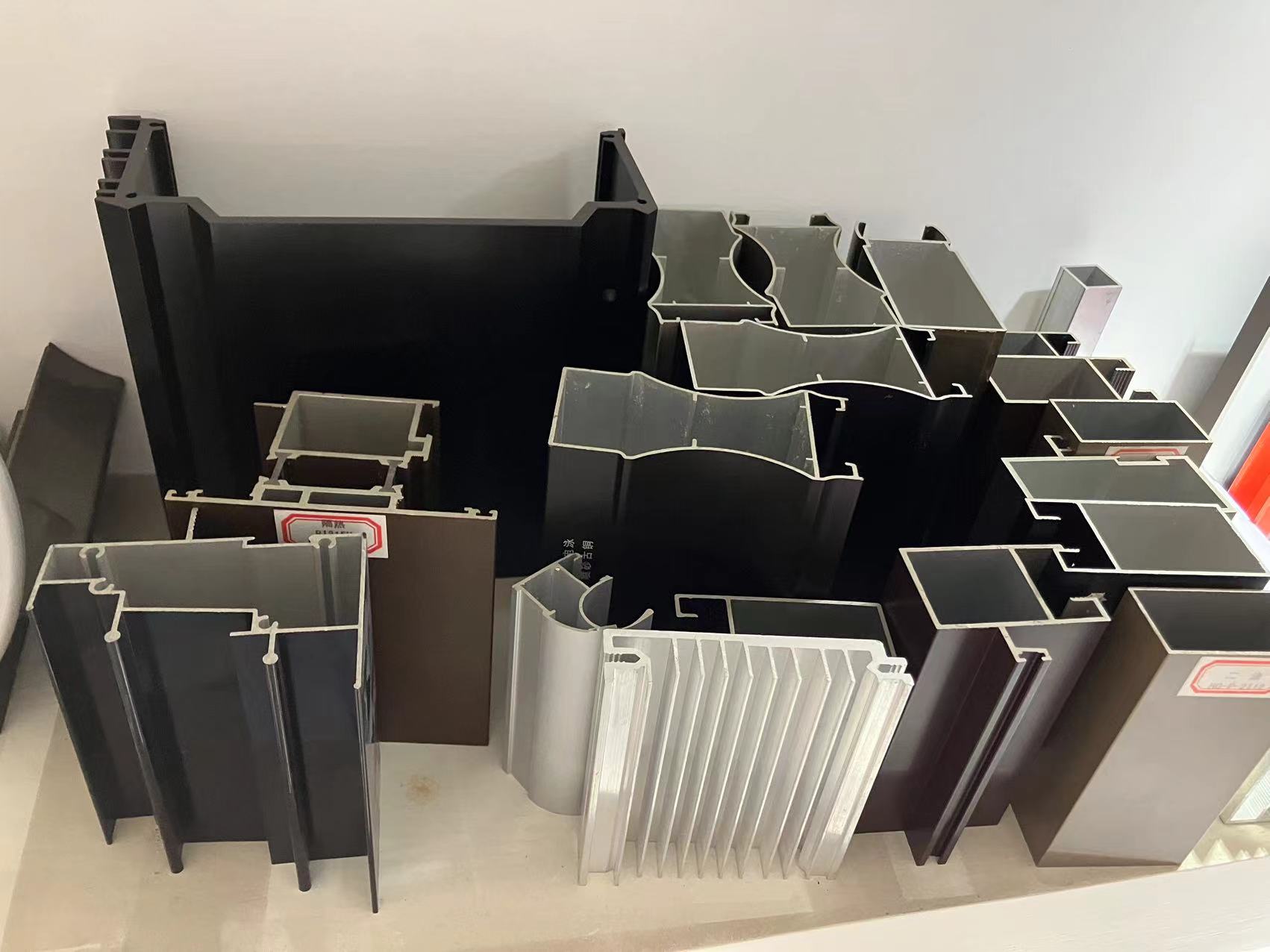

Aluminum radiator extrusion die, industrial profile extrusion die, large cross-section radiator extrusion molding die, die for shaped aluminum profile oxidation coloring aluminum products, extrusion aluminum alloy door and window die.

Aluminum profile extrusion die also has many advantages:

1. High precision:

Aluminum extrusion mold adopts advanced CNC processing technology, which ensures the dimensional accuracy and surface finish of the aluminum profiles produced.

2. High production efficiency:

The use of aluminum profile extrusion die can produce high-quality aluminum profiles quickly and in large quantities, which improves the production efficiency.

3. Energy saving and environmental protection:

Aluminum extrusion die adopts low temperature melting technology, which reduces energy consumption and environmental pollution.

4. Wide applicability:

Aluminum extrusion die can produce various specifications and shapes of aluminum profiles, which meets the needs of different industries.

Lastly

In aluminum extrusion processing, the die is indispensable. Its structure is divided into three parts which are positive die, die pad and die sleeve. By changing the shape of the die among them, the extruded aluminum can be used for various purposes. Using it also has the advantages of high precision, high efficiency and environmental protection. When you choose aluminum extrusion to process your products you should choose a suitable extrusion die.

Hugh Aluminum is an aluminum extrusion manufacturer based in China. We manufacture aluminum profile products including aluminum roofings,aluminum heat sink aluminum T-slot profile, aluminum deck, aluminum fence, aluminum doors and windows, solar aluminum frame. We offer large quantity of aluminum building materials and factory price.