Aluminum Square Tubes Coating Protection vs. Electro-galvanizing: Which is Better?

When comparing rust prevention methods for aluminum square tubes, two main techniques are coating protection and electro-galvanizing. Here’s a clear breakdown of each method:

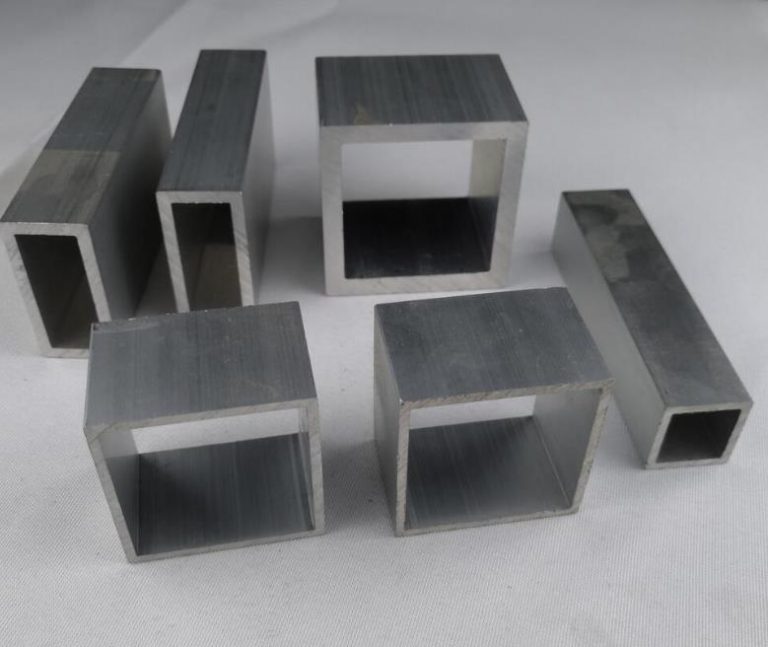

More products: Extruded aluminum tubes

Coating Protection

- Anti-Corrosion: Coating protection creates a strong barrier on the aluminum surface. Techniques like anodic oxidation or electrostatic powder spraying form a protective film that prevents corrosion by isolating the metal from moisture and air.

- Aesthetic Appeal: Coatings come in various colors and finishes. This allows for customization, making aluminum square tubes visually appealing for different applications.

- Durability: High-quality coatings last longer and require less maintenance. This means fewer repairs and replacements over time.

- Environmental Benefits: Many coatings, especially electrostatic powder sprays, are eco-friendly. They do not emit harmful solvents, making them a safer environmental choice.

Electro galvanizing

- Rust Resistance: Electro galvanizing applies a zinc layer to the aluminum surface. This layer effectively protects against rust, particularly in humid conditions.

- Cost-Effective: Compared to advanced coating technologies, electro-galvanizing is often more affordable. This makes it a practical choice for budget-conscious projects.

- Versatility: This method works well on various shapes of aluminum square tubes. The application process is straightforward and efficient.

- Maintenance Needs: While the zinc layer provides good protection, regular checks may be needed to ensure its effectiveness over time.

Final Thoughts

Coating protection is ideal for environments where aesthetics and long-term durability are essential. It offers excellent corrosion resistance and visual options.

Electro galvanizing is a strong choice for cost-effective rust prevention, especially in wet environments. It provides solid protection but may require more frequent maintenance.

Choose between coating protection and electrogalvanizing based on your specific needs, budget, and application context. For outdoor use or humid conditions, electro-galvanizing may be more suitable. Coating protection could be the better option for indoor applications prioritizing appearance and environmental safety.