Aluminum vs. Steel Square Tube: What Are The Differences?

Choosing between aluminum and steel square tubes can significantly impact your project. Both materials are widely used in industries like construction, automotive, and aerospace due to their unique strengths.

Aluminum square tubes are lightweight and resist corrosion, making them ideal for applications where reducing weight is essential. Steel square tubes, on the other hand, offer greater strength and durability, making them suitable for heavy-duty projects.

This article will break down the key differences between aluminum and steel square tubes, helping you select the best option for your specific needs.

More products: Aluminum Extrusions Tubes

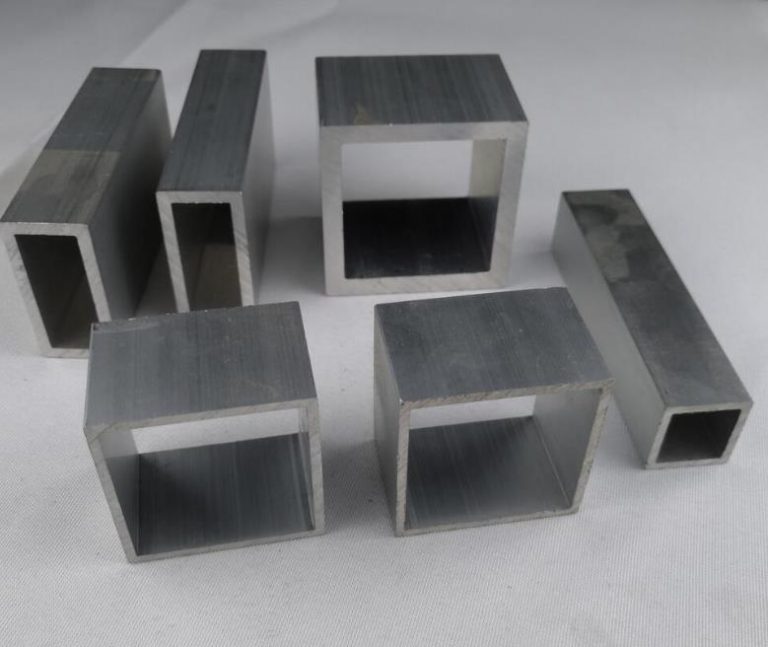

Aluminum Square Tube

An aluminum square tube is a hollow extrusion with equal sides. It is lightweight, strong, and resistant to corrosion, making it a versatile structural material.

Properties

High Strength and Light Weight

Aluminum square tubes combine strength with low density. This makes them lighter and easier to handle than steel, which is why they are widely used in construction and machinery.

Corrosion Resistance

Aluminum square tubes resist rust and perform well in harsh environments. They maintain their appearance and functionality over time.

Plasticity and Weldability

Aluminum square tubes are easy to bend, weld, and shape. These properties make them suitable for custom designs and varied applications.

Advantages

- Lightweight: Reduces the overall weight of structures and simplifies handling.

- Corrosion Resistant: Suitable for outdoor use or environments with moisture or chemicals.

- Aesthetic Appeal: This can be anodized for a polished finish and added protection.

- Recyclable: Aluminum is easy to recycle, reducing environmental impact.

- Simple Fabrication: Easy to cut, machine, and weld for various uses.

Disadvantages

- Lower Strength: Less strong than steel, limiting its use in high-stress applications.

- Cost: Can be more expensive than some steel grades depending on market conditions.

Applications

- Construction: Used for window frames, door frames, roofing, and lightweight structures.

- Automotive: Common in vehicle frames and body panels, especially for electric or lightweight vehicles.

- Aerospace: Utilized in aircraft frames and components.

- Marine: Found in boat structures, docks, and piers due to corrosion resistance.

- Consumer Products: Popular in furniture, outdoor equipment, and DIY projects.

Steel Square Tube

A steel square tube is a hollow pipe with equal sides, made from strip steel through various processes. It is a widely used building material due to its strength and impact resistance.

Types of Steel Square Tubes

Steel square tubes are classified based on production methods and materials:

- By Production Process: Includes hot-rolled seamless, cold-drawn seamless, extruded seamless, and welded square tubes.

- By Material: Includes plain carbon steel (e.g., Q195, Q215, Q235) and low-alloy steel (e.g., Q345, 16Mn).

Properties

- High Strength: Steel offers higher tensile and yield strength than aluminum, making it ideal for heavy-duty applications.

- Durability: Steel withstands significant impacts and heavy loads.

- Cost-Effective: Steel is often cheaper than aluminum, especially for construction projects.

- Weldability: Steel can be welded easily but requires more energy and equipment than aluminum.

- Thermal Conductivity: Steel has lower thermal conductivity compared to aluminum.

- Dimensional Accuracy: Stainless steel square tubes feature smooth surfaces and precise dimensions, often accurate to ±0.1mm.

Advantages

- Strength: Suitable for high-stress applications requiring load-bearing capacity.

- Durability: Performs well in harsh environments and under heavy use.

- Affordability: Cost-effective for large-scale or general construction projects.

- Availability: Comes in a variety of grades and sizes for different needs.

Disadvantages

- Weight: Heavier than aluminum, which may limit its use in weight-sensitive designs.

- Corrosion Risk: Susceptible to rust if not treated or coated properly, especially in outdoor or marine environments.

- Fabrication Difficulty: Harder to machine or cut compared to aluminum, requiring stronger tools.

Applications

- Construction: Used in building frames, columns, and structural supports.

- Automotive: Found in chassis, roll cages, and high-strength parts.

- Industrial: Used for machinery frames and equipment supports.

- Infrastructure: Commonly used in bridges, railings, and other large projects.

- Manufacturing Tools: Employed in jigs, fixtures, and other manufacturing aids.

Steel square tubes are strong, durable, and versatile materials suited for demanding applications across industries like construction, automotive, and infrastructure development.

Aluminum vs Steel Square Tube: Comparison Chart

| Feature | Aluminum Square Tube | Steel Square Tube |

|---|---|---|

| Weight | Lightweight | Heavy |

| Strength | Good strength-to-weight ratio | Higher tensile and yield strength |

| Corrosion Resistance | Excellent | Requires coating or treatment |

| Cost | Generally more expensive | Generally more cost-effective |

| Ease of Fabrication | Easier to cut, machine, and weld | More challenging to fabricate |

| Thermal Conductivity | Higher, beneficial for heat dissipation | Lower |

| Applications | Aerospace, automotive, marine, consumer goods | Construction, automotive, industrial, infrastructure |

How to Choose the Right Material?

Weight

Choose aluminum if weight is a critical factor. It is ideal for aerospace, automotive, and portable structures where lighter materials improve performance or usability.

Strength

Use steel for applications requiring high strength and durability. It is perfect for construction, heavy machinery, and infrastructure projects that handle significant loads or stress.

Corrosion Resistance

Select aluminum for environments exposed to moisture or chemicals, such as marine or outdoor settings. Its natural resistance to rust ensures long-lasting performance in harsh conditions.

Budget

Pick steel for cost-sensitive projects. Steel is generally more affordable than aluminum, making it a practical choice for large-scale construction or manufacturing.

Application-Specific Needs

Evaluate the specific requirements of your project to decide between aluminum and steel square tubing. Consider factors like load capacity, environmental exposure, and cost to select the material that best fits your needs.

Learn more: Aluminum tubes comparison complete guide