Anodized vs Powder Coat: Which is the Best Finish for Aluminum Project?

Choosing the right finish for your aluminum project is crucial. Anodizing and powder coating are two popular options that provide protection and visual appeal.

Anodizing creates a durable, corrosion-resistant surface by bonding with the aluminum. This finish is ideal for projects that need long-lasting wear resistance.

Powder coating offers a thicker, uniform layer that hides surface imperfections. It also provides a wide range of color choices, making it suitable for outdoor applications or parts that require extra durability.

Keep reading to learn how anodizing and powder coating compare and find out which option is best for your next project.

Anodized vs. Powder Coating: A Detailed Comparison

When choosing between anodizing and powder coating, it’s important to understand how each finish performs in key areas. The Aluminum Association highlights the need to select the right finish to enhance aluminum’s natural corrosion resistance, especially in outdoor or industrial settings. Both anodizing and powder coating have distinct advantages, but their suitability depends on your project’s specific requirements.

| Factor | Anodizing | Powder Coating |

| Durability | 10-15+ years in harsh conditions | 5-10 years in outdoor environments |

| Corrosion Resistance | High resistance (especially marine environments) | High, but depends on coating thickness |

| Color Options | Limited (10-20 colors, mostly metallic) | Wide variety (over 100+ colors and textures) |

| Environmental Impact | Low VOCs, energy-efficient | Low VOCs, energy-intensive curing |

| Cost | $5 – $15 per square foot | $2 – $8 per square foot |

Durability Comparison

Anodizing creates a highly durable finish, especially with hard coat anodizing (Type III). It can last 10 to 15 years or more in extreme conditions like aerospace or marine environments. The anodized layer integrates with the aluminum surface, making it resistant to scratches and wear. This makes anodizing ideal for high-traffic or industrial applications, such as aerospace components and automotive parts.

Powder coating also offers durability, protecting for 5 to 10 years in outdoor conditions, such as on automotive parts or outdoor furniture. It resists impacts, chipping, and scratches, but since the coating sits on top of the surface, it may be more prone to damage in heavy-duty applications. However, for outdoor furniture or automotive trim, powder coating provides sufficient durability for long-term use.

Corrosion Resistance

In terms of corrosion resistance, both finishes perform well but in different ways. Anodizing enhances aluminum’s natural corrosion resistance by forming a protective oxide layer. This layer effectively prevents rust and deterioration in outdoor applications. Anodized aluminum withstands harsh environmental conditions, including saltwater exposure, making it an excellent choice for marine and industrial settings.

Powder coating also protects against corrosion by forming a thick layer over the metal. It is ideal for parts exposed to moisture or chemicals, such as automotive components or metal fencing. The thickness of the powder coating – usually between 2 to 8 mils – affects its effectiveness. However, if the powder coating chips or cracks, the underlying metal may become vulnerable to corrosion.

Color Options

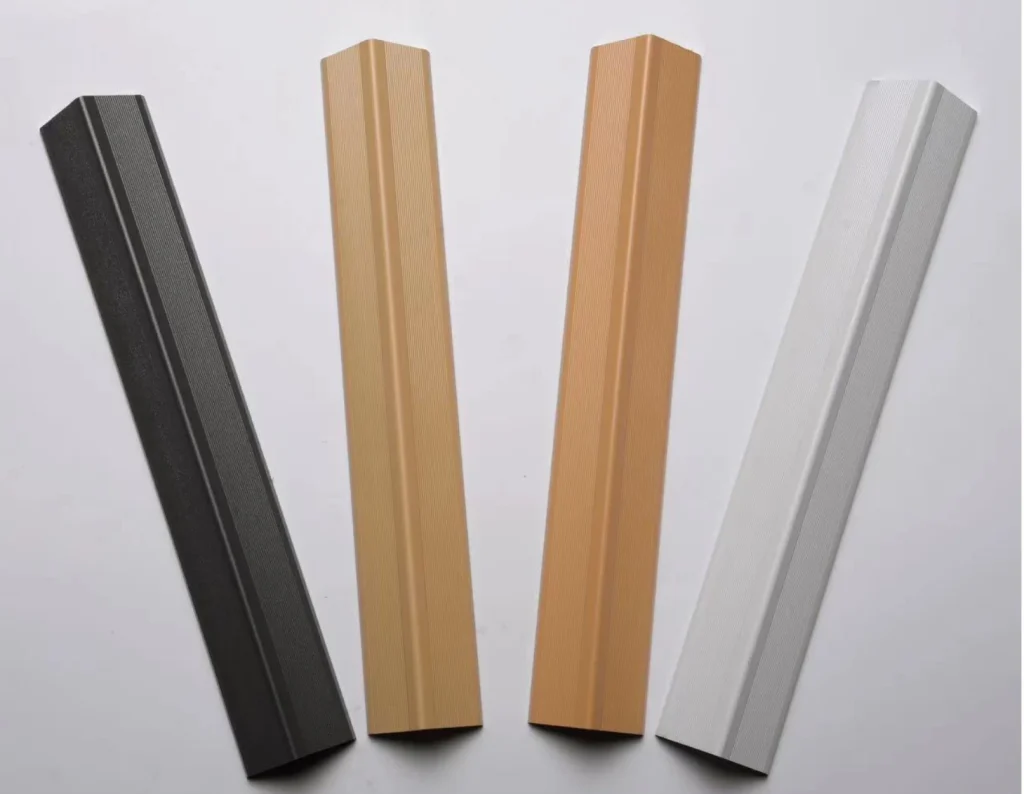

Powder coating has a clear advantage in color options. It offers over 100 colors and finishes, including matte, gloss, and textured choices. This versatility makes powder coating the preferred option for decorative applications where visual appeal is important.

In contrast, anodizing provides a more limited palette of around 10 to 20 colors, primarily metallic shades like bronze, silver, gold, and black. The anodizing process restricts the range of colors that can be applied, resulting in a more subdued finish compared to the vibrant colors available with powder coating. However, anodizing’s natural metallic look may be more desirable for applications requiring a sleek appearance.

Environmental Impact

Both anodizing and powder coating are environmentally friendly processes; however, anodizing has a slight edge regarding sustainability. The process does not emit harmful volatile organic compounds (VOCs) and uses relatively few chemicals that are mostly non-toxic and reusable. The byproducts of anodizing are easily neutralized and have minimal environmental impact.

Powder coating is also low-waste since overspray can be collected and reused. Additionally, it does not release harmful VOCs. However, the curing process for powder coating requires high temperatures and is energy-intensive, resulting in a larger carbon footprint compared to anodizing

Anodized vs Powder Coat: Cost

In terms of cost, powder coating is generally more affordable than anodizing—especially for large-scale projects. The average cost of powder-coating aluminum ranges from $2 to $8 per square foot based on complexity and thickness. It is less labor-intensive and requires fewer specialized tools. Powder-coating

Anodizing tends to be more expensive due to the precision required in its complex electrochemical process. Costs typically range from $5 to $15 per square foot depending on the type (Type I, Type II, or hard coat) and finish quality required. However, the long-term benefits of anodizing – such as superior durability and corrosion resistance – may justify the higher price for certain applications

Anodizing Aluminum: Basics, Types and Procedures

What is Anodizing?

Anodizing is an electrochemical process that thickens the natural oxide layer on aluminum. This process improves durability, enhances corrosion resistance, and provides a decorative finish. Unlike traditional coatings, anodizing bonds with the metal surface, making it a long-lasting solution for projects that need both strength and aesthetics.

Industries such as aerospace, architecture, and consumer electronics commonly use anodizing for its ability to add visual appeal and functional protection. Anodized aluminum retains its color over time, resists chipping and fading, and offers an environmentally friendly finish with no volatile organic compounds (VOCs).

How Does Anodizing Work?

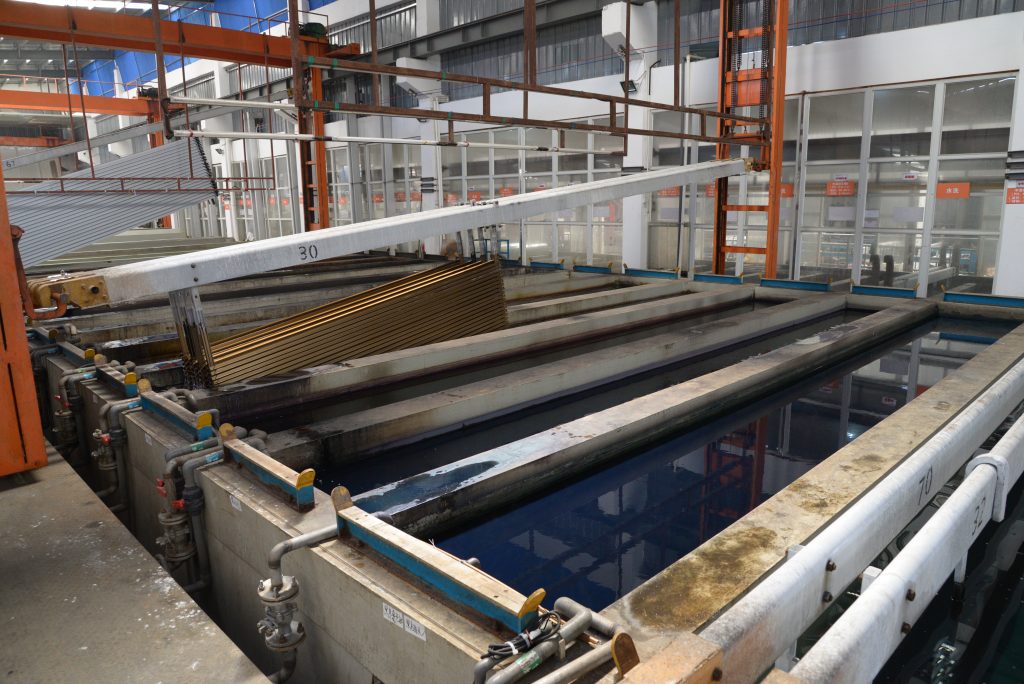

The anodizing process involves submerging aluminum in an electrolyte bath, typically sulfuric acid. The aluminum serves as an anode while a cathode is placed in the bath. When electrical current flows through the solution, the aluminum reacts with oxygen to form aluminum oxide. This oxide layer grows thicker and stronger, providing significant protection against corrosion and wear.

One advantage of anodizing is that the oxide layer is porous. This allows it to absorb dyes for color finishing. The final step involves sealing the anodized surface to lock in the protective layer and color. The result is a smooth, durable finish suitable for both indoor and outdoor applications.

Types of Anodizing

Different types of anodizing are suited for specific applications:

- Type I (Chromic Acid Anodizing): This method creates a thin, flexible layer that offers good corrosion resistance. It is often used in aerospace applications where weight is a concern but protection is still necessary.

- Type II (Sulfuric Acid Anodizing): The most common type of anodizing, Type II provides a thicker protective layer. It is frequently used for architectural and consumer products due to its ability to absorb dyes and create vibrant colors.

- Type III (Hardcoat Anodizing): Known for its extreme durability, hardcoat anodizing produces a thick, wear-resistant layer ideal for heavy-duty applications.

What Are the Best Applications for Anodizing?

Architectural Applications

Anodizing is great for architectural projects because it’s durable and corrosion-resistant. Anodized aluminum lasts 15 to 20 years outdoors so it’s perfect for buildings and structures that are exposed to the elements. Common uses are curtain walls, window frames, and roofing systems. The anodized surface resists UV and weathering and doesn’t fade or peel. Plus 10 to 20 metallic colors to add a modern look to your design.

Industrial Applications

In industrial applications, anodized aluminum is used because it can withstand harsh conditions. Hardcoat anodizing provides 25 to 50 microns of thickness and is abrasion and chemical-resistant. It’s great for heavy-duty equipment and machinery components like housings and aerospace parts where durability is key. Anodized aluminum can last over 20 years, especially in marine or aerospace industries where exposure to saltwater or chemicals is common.

Consumer Products

Anodized aluminum is used in consumer products because of its look and practicality. It’s common in electronics like smartphones, laptops, and tablets for scratch resistance and a sleek look. Anodized aluminum can last 5 to 10 years of regular use while maintaining its finish, perfect for high-end kitchen appliances and cookware. The smooth durable finish helps these products retain their quality and looks over time.

Aluminum Powder Coating: Basics, Process and Types

What is Powder Coating?

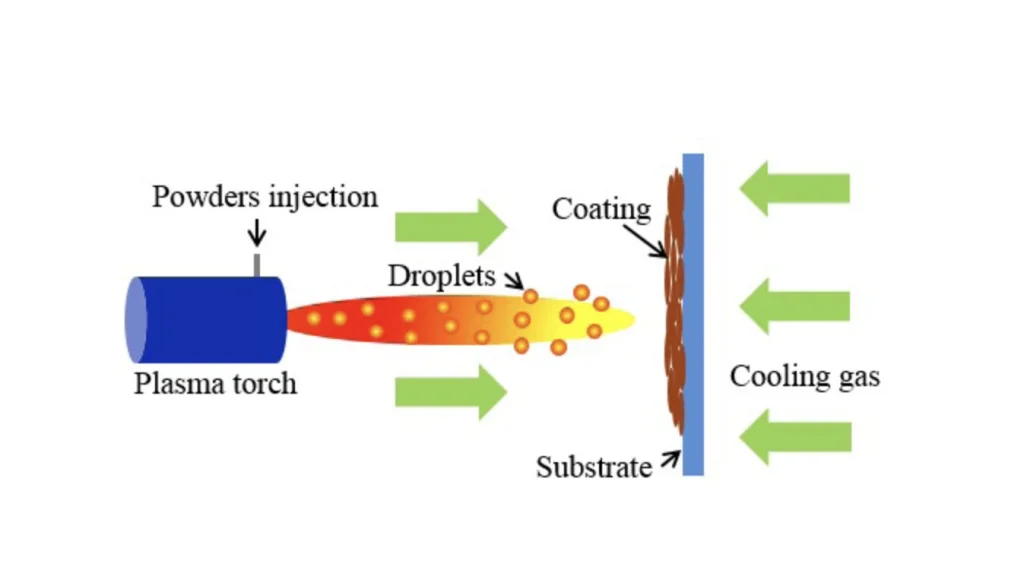

Powder coating is a finishing process that applies dry powder made of resin, pigment, and other ingredients to metal surfaces. The powder is electrostatically charged and sprayed onto the metal. After application, the part is cured in an oven, where the powder melts and forms a smooth, durable layer. This coating protects against corrosion, UV rays, and general wear, making it a popular choice for both indoor and outdoor metal products.

Unlike traditional liquid paint, powder coating does not require solvents, making it more environmentally friendly. It offers various textures and colors to match different design preferences. Whether for automotive parts, outdoor furniture, or architectural fixtures, powder coating provides reliable high-performance finishes.

How Does Powder Coating Work?

The powder coating process starts with preparing the metal surface. Clean the substrate to remove oil, dirt, and rust to promote proper adhesion. After preparation, grind the metal part and spray the powder onto it using a powder spray gun. The electrostatic charge helps create an even coat across the entire surface.

Once the powder is applied, place the metal part in a curing oven at around 400°F. The heat melts the powder, allowing it to flow and bond with the metal surface. This curing process solidifies the coating, making it resistant to chipping, fading, and corrosion.

Types of Powder Coatings

Several types of powder coatings are available:

- Epoxy Powder Coatings: These coatings offer strong adhesion and durability for indoor use. However, they can degrade with UV exposure, making them unsuitable for outdoor applications.

- Polyester Powder Coatings: These coatings resist UV exposure well and are ideal for outdoor applications like fences and automotive parts. They provide excellent weather resistance and maintain their color over time.

- Hybrid Powder Coatings: A blend of epoxy and polyester, hybrid coatings combine the strength of epoxy with the UV resistance of polyester. They are suitable for both indoor and outdoor applications where durability and cost-effectiveness matter.

Understanding these aspects of powder coating helps you choose the best finish for your aluminum projects.

What are the Best Uses for Powder Coating?

Automotive

Powder coating is used in the automotive industry for its durability and impact/chemical resistance. Powder-coated wheels, frames, and exterior parts can last 5-10 years in harsh environments, road debris, salt, and UV. Typical powder coating thickness is 2-8 mils, providing strong chipping and corrosion protection. Manufacturers and custom shops can create vibrant lasting finishes for both decorative and functional automotive parts.

Furniture and Home Decor

In furniture and home decor, powder-coated aluminum and steel are popular for their color and wear resistance. Powder coating lasts over 10-15 years indoors, and provides essential scratch and chip resistance for high-use items like chairs, tables, and shelves. With over 100 color and texture options available homeowners and designers can create custom pieces to fit any interior style.

Outdoor Equipment

Outdoor equipment like playground structures, fences, and garden furniture benefits greatly from powder coating. The thick layer can withstand 10-20 years of UV, rain, and moisture without fading or deteriorating. Applied at 4-8 mils powder coating provides excellent impact resistance and long-term durability in extreme weather. It’s perfect for outdoor environments that require low maintenance high-performance finishes.

Anodized vs Powder Coat: How to Choose the Right Finish?

Appearance

When choosing between anodizing and powder coat, think about the look you want for your finished product. Anodizing has a natural metallic finish and comes in about 10 to 20 metallic colors, good for a sleek industrial look. The powder coat has over 100 colors and finishes, including matte, high gloss, and textured. If you need bright colors or unique textures, a powder coat is the way to go.

Functionality

Think about the functionality of your project. Anodizing, especially hard coat anodizing, provides excellent corrosion resistance and can last over 20 years in marine or industrial environments. It’s good for applications that require high durability against scratching and extreme weather. Powder coat lasts 5 to 10 years in harsh outdoor conditions and has good impact resistance. It’s good for automotive parts, outdoor furniture, and other high-wear items.

Budget

Budget is another consideration. Powder coat is generally more affordable, $2 to $8 per square foot depending on complexity and finish. For large projects or cost-sensitive applications, a powder coat is a great value for protection.

Anodizing is $5 to $15 per square foot and is more expensive due to the precision and equipment required for the process. While anodizing provides superior corrosion resistance and long-term durability, it may not be as cost-effective for tighter budgets.

For those interested in technical specifications and detailed research on anodizing and powder coating, ASM International is a valuable resource for understanding surface treatments.

Final Thought

Anodizing or powder coating? It’s all about your project. Both are great for durability, protection, and looks. Anodizing is good for projects that need a sleek metal look with superior corrosion resistance. Powder coating is good for outdoor and high-impact applications.

At Hugh Aluminum, we do both anodizing and powder coating. We guarantee great finishes on your aluminum products. Whether you are working on an architectural, industrial, or consumer project we can help.

Which finish is right for your next aluminum project? Contact us today to discuss how we can help you achieve the perfect finish!