Aluminum Extrusions’ Applications & Cases Studies

Welcome to Hugh Aluminum, the go-to name in premium aluminum extrusions. Our products are the backbone of many industries because of their versatility, strength, and lightness.

Here we go into specific examples and real-world case studies that show the performance and multipurpose of our aluminum extrusions. These case studies not only show the uses of our products but also our commitment to quality and customer satisfaction.

Case Study 1 – Aluminum Decking Installation

Our aluminum deck project is located at People’s Park on Nanmen Street, Huiyang District, Huizhou, Guangdong Province. We just finished the aluminum decking project and now the park has a new spot for leisure.

Our decking planks are 150mm wide and 22.5mm thick. The construction team from the 6th Construction Bureau chose Hugh Aluminum’s deck design because it’s strong and good-looking.

People’s Park in Huiyang is a key green space in Huiyang District and is very popular. To upgrade the park facilities and visitor experience, the decision-makers chose aluminum decking for the park. Aluminum is corrosion resistant and low maintenance so it was an easy choice.

The Construction Process

- Survey and Design: Before we started we surveyed the site and designed the project. The aluminum decking path was designed along the main walking routes and connected all the different areas of the park.

- Preparation: First we cleared the ground to level it. Then we located the joist positions according to the design and made sure they could take the load of the aluminum decking.

- Joist Installation: We used high-strength aluminum alloy beams as joists. The spacing was calculated well so the floor could bear the weight of people walking on it.

- Decking Installation: With the joists in place the decking was installed. Each plank is 150mm wide and 22.5mm thick. We used M8x100mm bolts to anchor them. The installation method was very straightforward and the decking is as solid as a rock.

- Finishing: After all the decking was laid the team checked the seams to smooth out the edges. They added anti-slip strips for safety.

Done in a week and the aluminum decking is ready for use. Visitors can now sit and socialize in this new area. The deck beautified People’s Park and made the public space more functional. Now it’s a great place for citizens to chill out.

Case Study 2 – Aluminum Window Installation

The Nanyi Apartments in Changsha, Hunan, serve as a case study for aluminum window installation. This project involves the complete engineering and installation of aluminum windows throughout the apartment complex.

We have completed the production of the whole building’s aluminum windows. Our team designed and made the windows to perform well and long-lasting, and meet the modern construction standards of safety, durability, and beauty.

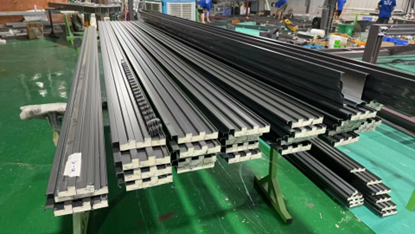

Design and Manufacturing

Our aluminum windows are designed and made to stand out:

- High-quality materials: We used high-strength aluminum alloy, anodized. Not only looks good but is also anti-corrosion, suitable for various weather conditions.

- Advanced design: Airtight and watertight, the windows use advanced sealing technology, preventing air and moisture from entering, creating a comfortable indoor environment.

- Long life: Our windows have been strictly tested, have more than 20 years of life, and can withstand long-term use and harsh external conditions.

- Safety features: Designed for safety, the windows have reinforced glass and strong locks, anti-damage, and home and property security.

Project Background and Construction Process

For the Nanyi Apartments project, we took into account the local climate. Changsha has heavy rain and high humidity, wind pressure resistance is very important. Our aluminum windows have been tested to withstand strong wind during typhoons and ensure residents’ safety and comfort. And to combat humidity, our windows meet the high standard of door and window seals, and prevent water seepage.

During construction, our team measured the installation area to ensure the window size is accurate. According to our drawings, the aluminum windows were installed with high-strength fasteners and sealing materials, to ensure the window fit the building wall tightly.

Our aluminum windows look good and perform well. Residents can get plenty of natural light and ventilation without worrying about the weather. This project not only increased the value of the apartments but also proved Hugh Aluminum’s capability in aluminum extrusion.

Enjoy this engineering story – it’s about good design, good manufacturing, and care for residents.

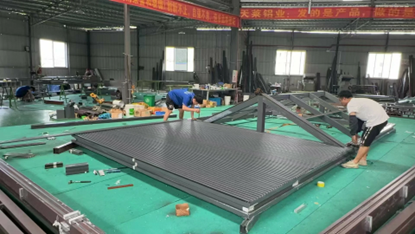

Case Study 3 – Aluminum Insulated Roofing Installation

Who would have thought finding the right roofing material would be like finding the missing puzzle piece? In the beautiful Gaoming District of Foshan, Guangdong, our aluminum extrusion insulated roof tiles were the showstopper at the Holiday Inn garden pavilion. These tiles with polyurethane core have fire and thermal insulation properties, perfect for buildings that need safety and function.

Material Wonders

- Thermal Barrier 1.1. Polyurethane is the magic ingredient. Like a knight in shining armor, it blocks external heat, keeps the indoor temperature comfortable, and saves air-conditioning costs. And it’s energy saving.

- Fire-Resistant 2.1. Our tiles can take the heat—literally. The specially treated polyurethane provides excellent fire resistance, reduces the risk of fire, and adds a layer of safety to the hotel setup.

- Lightweight & Tough 3.1. These tiles are like the incredible hulks of roofing materials. They’re light enough to lift with ease, yet tough and durable, and can withstand any weather Mother Nature throws at them.

At Holiday Inn, installation of the insulated aluminum tiles was a walk in the park, literally a Sunday morning. The construction team started with a thorough roof inspection to make sure the base was solid. Then the design team from Hugh Aluminum joined the construction team to work out the installation plan.

The magic of these tiles? They come with their own hot-melt glue. Installation was a piece of cake—just stick them according to the blueprint on the beams, save time and labor. Once in place, the team sealed the joints with precision to ensure waterproofing and insulation.

After the construction was done, the Holiday Inn’s roof was rocking the new aluminum extrusion insulated tiles. Not only did the tiles give the hotel a facelift but also increased the comfort level inside. The hotel management was so happy, especially with the thermal and safety performance.

With this case, we have shown the superiority of our insulated aluminum roof tiles. They’re not just pretty faces but they have a lot to offer in modern architecture. We look forward to using this high-performance roofing material in our future projects and providing safe and cozy solutions for more buildings. Who knew roofing could be this cool?