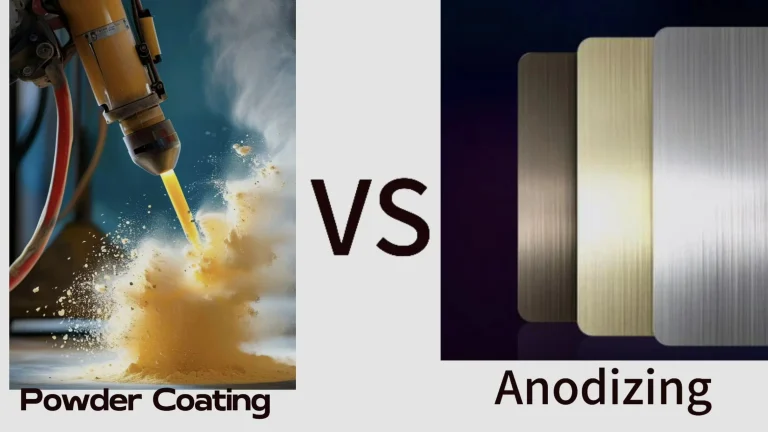

Anodized vs Powder Coat: Which is the Best Finish for Aluminum Project?

Choosing the right finish for your aluminum project is crucial. Anodizing and powder coating are two popular options that provide protection and visual appeal. Anodizing creates a durable, corrosion-resistant surface by bonding with the aluminum. This finish is ideal for projects that need long-lasting wear resistance. Powder coating offers a thicker, uniform layer that hides…