Classification of Aluminum Alloy

Basic Concept of Aluminum Alloy

Aluminum is a lightweight, less corrosive metallic material with a wide range of applications in many fields. Since aluminum as a pure metal has low strength and hardness, it is necessary to improve its properties and range of application by alloying it with other metallic materials.

Classification of Aluminum Alloys

1. Pure Aluminum (A series): Requirements for aluminum content above 99%, excellent plasticity and workability, but relatively lacking in hardness and strength.

2. aluminum-copper alloys (C series): containing copper 0.2-4.0%, relatively high strength and hardness.

3. aluminum-manganese alloy (M series): containing manganese 0.8-1.2%, with good corrosion resistance and workability.

4. aluminum-silicon alloy (4 series): containing silicon 4.5-13.5%, with good rheological properties and processability.

5. aluminum-magnesium alloy (5 series): containing magnesium 2.5-6.0%, with good strength and corrosion resistance.

6. aluminum-zinc alloy (7 series): containing zinc 4.0-7.5%, with good strength and workability.

7. aluminum-tin alloy (8 series): containing 8.0-12.0% tin, with good fastness and heat resistance.

Aluminum alloys have the following characteristics:

1. light weight:

Relative density is around 2.7, 1/3 lighter than steel.

2. Strong corrosion resistance:

Aluminum itself has good corrosion resistance, and can be oxidized and other surface treatment to improve its corrosion resistance.

3. Good workability:

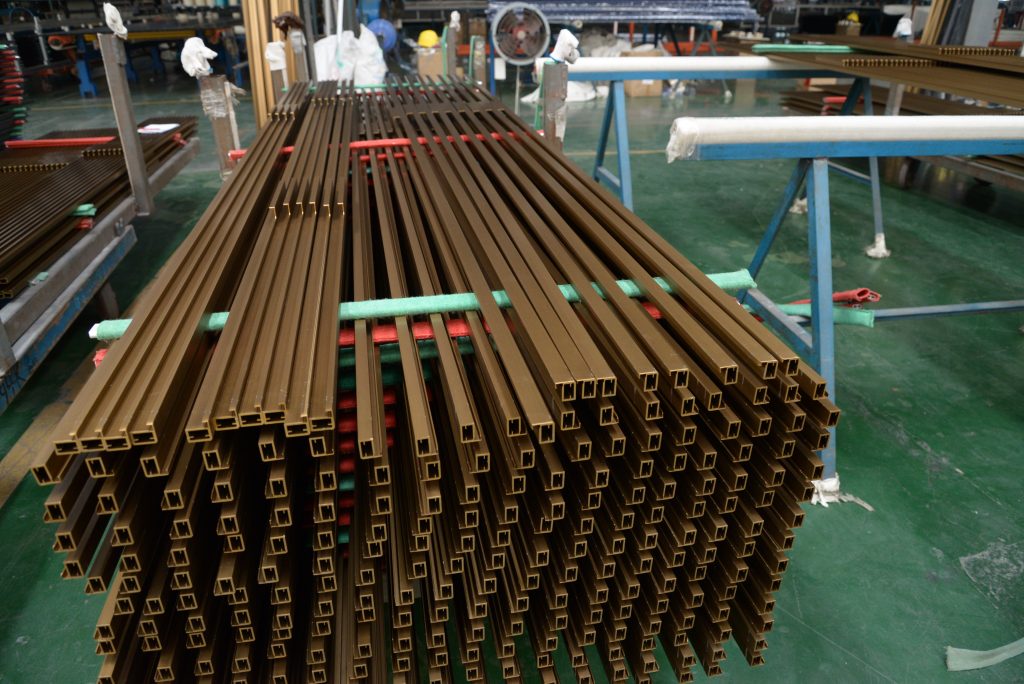

Aluminum has excellent plasticity and workability, can be forged, casting, extrusion and other ways to shape.

4. Good thermal conductivity:

Aluminum has good thermal conductivity, is the ideal material for many electrical and electronic components.

5. Special features:

Aluminum alloys can be added with other elements and enhanced with different treatments for special functions such as oxidation resistance, heat resistance, wear resistance and so on.

Application of aluminum alloy

1. Vehicle manufacturing field:

Aluminum alloy can be used in the manufacture of various vehicles such as automobiles, locomotives, airplanes and so on, in order to improve their quality, strength, reduce fuel consumption and so on.

2. construction field:

Aluminum alloy can be used in the manufacture of doors, windows, curtain walls, ceilings and other building decoration materials to improve the decorative effect and corrosion resistance.

3. Packaging field:

Aluminum alloy can be used in the manufacture of food packaging materials such as beverage cans and pharmaceutical packaging to improve packaging quality and freshness.

4. electronics field:

Aluminum alloy can be used in the manufacture of electronic components such as electronic products, cell phone shells, electrolytic capacitors, etc. to improve heat dissipation and conductive properties.

In conclusion

As a widely used material, aluminum alloy has a very important position in different fields. It is believed that with the continuous progress of science and technology and the continuous R&D and innovation of aluminum alloy materials, the application prospect of aluminum alloy in the future will also be broader.

Hugh Aluminum is an aluminum extrusion manufacturer based in China. We manufacture aluminum alloy profile including aluminum roofings,aluminum heat sink aluminum T-slot profile, aluminum deck, aluminum fence, aluminum doors and windows, solar aluminum frame. We offer large quantity of aluminum building materials and factory price.