Critical Control Factors for Aluminum Extrusion Processing

How to extrude high quality aluminum profiles has always been a problem for extruded aluminum manufacturers. Let’s look for the factors that control quality in aluminum extrusion today.

1. Mold design:

The design of the die directly affects the shape, size and mechanical properties of aluminum alloy profiles. Therefore, reasonable mold design is one of the key factors in extrusion processing.

2. Extrusion speed and pressure:

The control of extrusion speed and pressure is crucial to the quality and performance of aluminum alloy profiles. Too fast or too slow extrusion speed and too little or too much pressure will lead to the decline in the quality of the profile.

Belows video From Hugh Aluminum shows how to extruding aluminum

3、Cooling and straightening:

The choice of cooling speed and straightening method will affect the microstructure and mechanical properties of aluminum alloy profiles. Fast cooling and correct straightening method can get better material properties.

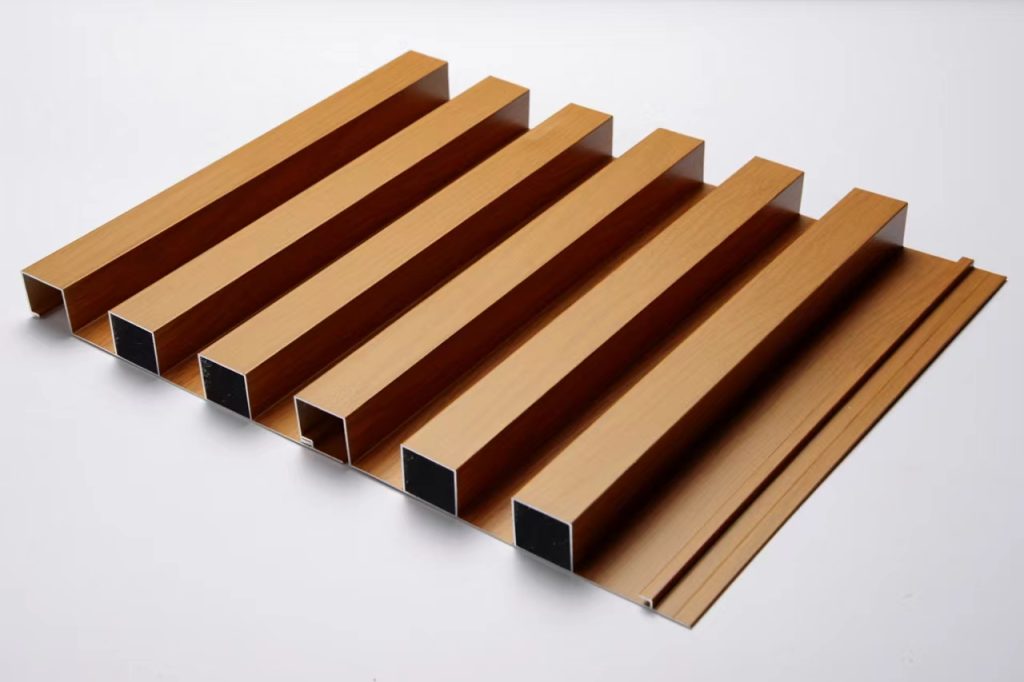

4、Surface treatment and cutting:

Choose the appropriate surface treatment method according to the product requirements, and at the same time ensure the cutting precision and stability to meet the length, size and shape requirements of the product.

5、Quality testing and packaging:

Strict quality testing procedures can ensure that the quality of the product meets the requirements, and suitable packaging methods can protect the product from damage during transportation and storage.

6. Preheating and temperature control:

Aluminum rods are heated to soften them before they are subjected to extrusion. The purpose of this is to make it easier to deform when extruded. However, care should be taken to control the preheating temperature and whether the temperature of the aluminum bar during extrusion meets the requirements. If the temperature is lower than the standard, there will be problems of fracture and surface pitting after extrusion.

In summary

Aluminum extrusion is an important method of metal forming process with the advantages of high efficiency, low cost and high quality. We can control: die, extrusion speed and pressure, surface treatment, cooling and other factors. Only understanding and mastering the whole process of aluminum extrusion processing and its key control factors can help to improve the productivity and product quality.

Hugh Aluminum is an aluminum extrusion manufacturer based in China. We manufacture extruded aluminum products including aluminum roofings,aluminum heat sink aluminum T-slot profile, aluminum deck, aluminum fence, aluminum doors and windows, solar aluminum frame. We offer large quantity of aluminum building materials and factory price