Differences between drawn and extruded aluminium

drawn and extruded aluminium as common aluminium products. The difference between the two of them is significant and therefore they can differ in product characteristics and use.

Let Hugh Aluminium take you on a journey to find the differences between them today:

How they are processed?

1. Extruded aluminium

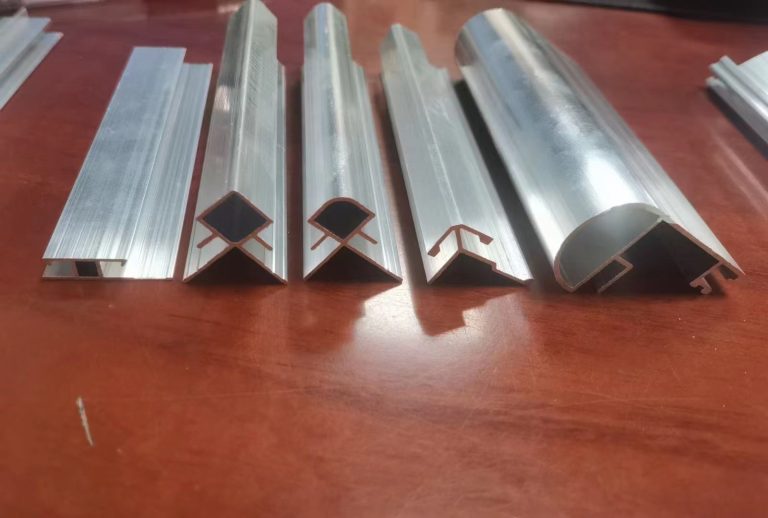

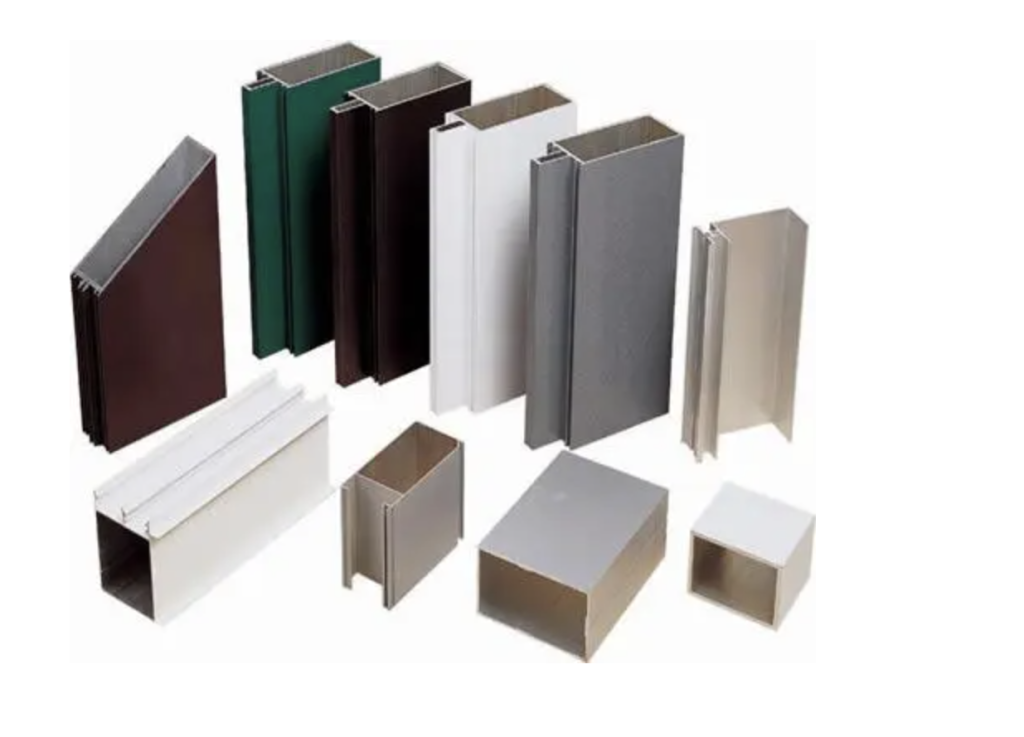

Extruded aluminium is formed by heating and extruding an aluminium billet through an extruder, and is usually used to produce a variety of profiles and parts.

Processing method: Aluminium billet is heated and forced or pushed through a die by an extruder, and the product coming out of the other end is formed into the desired end product through a die.

2. drawn aluminium

Aluminium drawing refers to the process of stretching aluminium products under certain conditions in order to change their shape and properties.

Processing: The aluminium product is drawn or pulled into the mould cavity and undergoes plastic deformation to obtain the desired shape. When stretching, attention should be paid to the flexibility and elasticity of the metal to avoid overstretching resulting in brittleness.

Material properties of extruded and drawn aluminium

1. Extruded aluminium

Performance characteristics: Extruded aluminium has high forming precision, accurate dimensions, uniform density and smooth surface. In addition, it has good workability and weldability, and a long service life.

2. Drawn aluminium

Shape and properties: Stretched aluminium changes its shape and properties through stretching process, which makes the aluminium material more uniform and delicate and improves its plasticity and toughness.

Stretching Requirements: During the stretching process, close attention needs to be paid to the flexibility and elasticity of the metal to avoid over-stretching resulting in brittle material.

About their fields of application

1. Extruded aluminium

o Construction field: it is commonly used in the production of aluminium alloy doors and windows, curtain walls, fences, stair handrails, etc.

Industrial field: Aluminium extrusion can produce various profiles and parts such as tubes, doors, window frames, brackets and railings.

2. Drawn Aluminium

Industrial field: It is mainly used to produce products such as fine wires and thin plates, which are widely used in aerospace, automobile manufacturing, electronic equipment, etc.

Cost & Efficiency:

- Extruded aluminium is usually less costly because the extrusion process is highly efficient in terms of production and material utilisation.

- Extruded aluminium can be slightly more costly because the drawing process requires finer control and more post-processing.

Final Summary

Extruded and drawn aluminium are two different processes for processing aluminium. They differ significantly in terms of material properties, processing methods, application areas, cost and efficiency.

Hugh Aluminum is a manufacturer of Aluminium extrusions. We design and manufacture all types of extruded aluminium.

If you need to purchase aluminium products in bulk or looking for aluminium suppliers?

Please contact us! We have 14 years of manufacturing experience and served more than 600+ customers from 40+ countries. Our team is friendly and professional.

Please contact us!