Best Types of Aluminum Finishes: Complete Guide to Benefits and How to Choose

Most aluminum products need a finish. This finish protects the metal and improves its appearance. Many companies sell aluminum parts but know little about the finishing process. This can lead to confusion or mistakes.

This article explains each type of aluminum finish. You will learn what each finish does and why you might choose it. By the end, you will know which finish fits your project best.

Let’s get started and find the best finish for your aluminum parts.

Types of Aluminum Finishes

Aluminum products can have many different finishes. The most common types are anodizing, powder coating, mill finish, woodgrain, and PVDF.

Each finish changes how the aluminum looks and performs. Anodizing creates a hard, protective surface. Powder coating adds color and resists scratches. Mill finish is raw aluminum with no extra treatment. Woodgrain gives a wood-like appearance. PVDF offers strong weather resistance.

This section explains these finishes. You will see how each one works and what benefits it offers. Use this guide to choose the finish that matches your project needs.

What is Powder Coating?

Powder coating is a surface treatment for aluminum. This process covers the metal with a dry powder. The powder sticks to the surface using static electricity.

Workers spray the powder onto the aluminum. The coated parts go into an oven at 180 to 210 degrees Celsius. The heat melts the powder and forms a hard, smooth layer.

Powder coating protects aluminum from scratches and weather. It also gives the metal a bright, even color. This finish is strong and lasts for years.

In short: powder coating makes aluminum look good and stay protected.

Advantages of Powder Coating Finish

Powder coating does not use liquid solvents. This reduces air pollution and keeps harmful fumes out of the environment. Workers can collect and reuse extra powder, which cuts down on waste.

Powder coating forms a smooth and even layer on aluminum. This layer protects the metal from rust and scratches. It also makes the surface harder and more durable.

With powder coating, aluminum parts last longer and look better. This finish is a smart choice for strong protection and bright color.

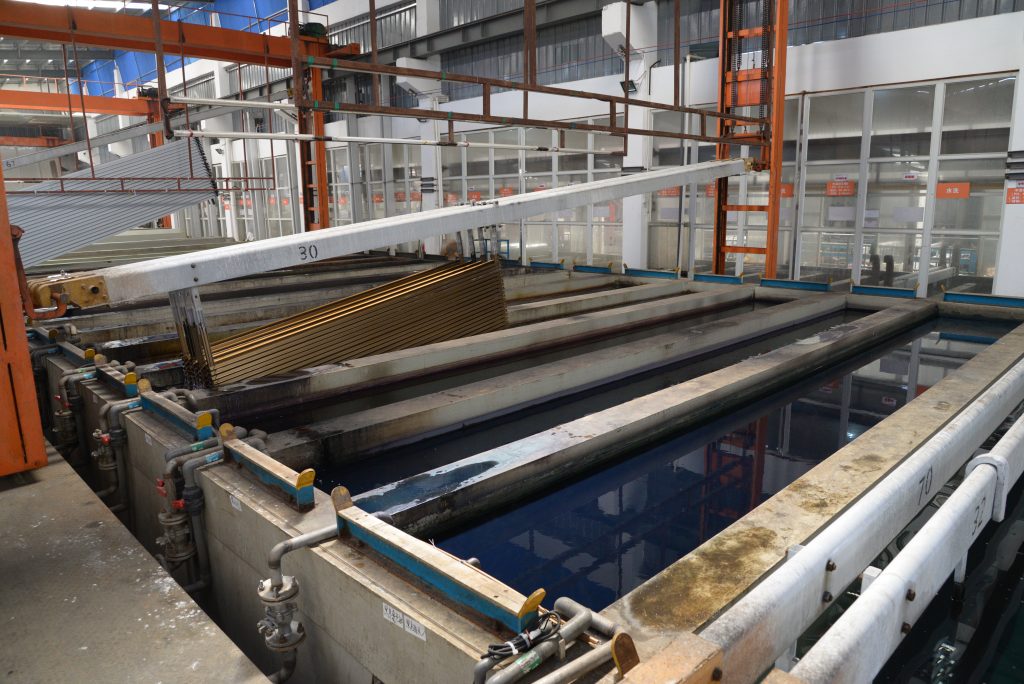

What is Anodizing Finish?

Anodizing is an electrochemical process for aluminum. Workers place the aluminum in an electrolyte bath. They use electricity to form a thin oxide layer on the surface.

This oxide layer protects the aluminum from corrosion and scratches. The process can also add color. Workers add dyes to the electrolyte, and the color bonds with the oxide layer.

Anodizing gives aluminum a strong surface and a lasting finish. The result is metal that resists wear and keeps its color.

Advantages of Anodizing Finish

Anodizing gives aluminum strong electrical insulation. The oxide layer does not let electricity pass through. This makes anodized aluminum safe for electronic enclosures and parts that must not conduct electricity.

If you need a material that blocks current, anodized aluminum is a smart choice.

What is Mill Finish Aluminum?

Mill finish aluminum is raw aluminum with no extra coating or treatment. The surface looks metallic and may appear dull. The metal comes straight from the extrusion process.

Why Choose Mill Finish Aluminum?

Mill finish aluminum keeps the natural look of the metal. It costs less because it skips extra processing. Many people use it for projects with tight budgets.

Designers also use mill finish aluminum for its industrial style. The raw surface gives a modern and bold look to buildings and interiors. If you want a simple and strong appearance, mill finish aluminum is a good choice.

What is Woodgrain Finish?

Woodgrain finish makes aluminum look like wood. The process uses heat and pressure to bond ink patterns to the metal surface. This creates lines and colors that copy real wood.

Many people choose a woodgrain finish for its style. It gives aluminum the appearance of wood but keeps the strength and low maintenance of metal.

Woodgrain finish is a good choice if you want the look of wood without the problems of rot or insects. It works well for doors, windows, and furniture.

Wood-like Appearance

Woodgrain finish gives aluminum a wood look. The process creates patterns and colors that match real wood.

This finish works well for outdoor railings. It resists corrosion and weather. Railing makers use woodgrain aluminum because it keeps the style of wood and the strength of metal.

You get the look of wood without the worry of rot or splinters.

What is PVDF Finish?

PVDF finish uses a polyvinylidene fluoride coating on aluminum. Workers spray the PVDF resin onto the metal. They then bake the coated aluminum at 180 to 250°C to cure the layer.

The PVDF coating sticks firmly to the surface. It does not peel or chip after many years. This finish keeps color and protects aluminum from weather and sunlight.

PVDF finish is a good choice for projects that need long-lasting color and strong protection.

Benefits of Using PVDF Finish

PVDF finish protects aluminum from sun, rain, and wind. The coating blocks UV rays and keeps its color in harsh weather. Builders use PVDF for railings and wall panels because it lasts.

PVDF coating sticks tightly to aluminum. It holds better than powder coating or anodizing. The finish does not peel or fade easily.

Manufacturers use PVDF on golf clubs, tents, and water bottles. This finish keeps products looking new for years.

Which is the Best Aluminum Finish Option?

For Durability

Choose anodizing or PVDF finish for strong protection. Both finishes create a layer that blocks corrosion and UV damage. These options work well for outdoor or high-use parts. They cost more than other finishes.

For Color and Style

Select powder coating for many color choices. Powder coating offers a smooth, colorful surface. You can pick from hundreds of shades and finishes. This option is good for creative designs.

For a Wood Look

Pick a woodgrain finish if you want aluminum to look like wood. This finish copies wood’s color and texture. It works well for railings, doors, or panels. Woodgrain aluminum lasts longer than real wood in outdoor settings.

For a Budget Option

Use mill finish aluminum if you want the lowest cost. Mill finish is raw metal with no extra coating. It works for indoor projects or places where corrosion is not a big risk. Do not use mill finish near the sea, as salt can damage the surface.

Choose the finish that matches your project’s needs, budget, and style.

Final Thoughts

Choose your aluminum finish based on your project needs and budget. Review each option and compare the benefits.

Anodizing, powder coating, PVDF, and woodgrain are common finishes. Other finishes may also fit your project.

Finishing aluminum is not simple. It requires skill and the right tools. Hugh Aluminum offers several finishing services. These include powder coating, anodizing, anodic electrophoresis, and woodgrain effects.