Extruded Aluminum seamless bending process details

Basic Principles of Extruded Aluminum Bending

Aluminum profile bending refers to the flat aluminum profile bent into the desired corner. The principle of aluminum profile bending is that while the internal strain state is changed, the surface stress is also changed. This results in the bending of the aluminum profile to achieve the desired shape.

The bending angle and bending radius of aluminum profile depends on the material and cross-section shape of the aluminum profile, as well as the performance of the bending equipment and process parameters.

Extruded aluminum bending method

1. Cold bending method

Cold bending method refers to the bending of aluminum profiles at room temperature. The use of cold bending method of bending aluminum profiles do not need to be heated, the operation is simple, suitable for small angle bending.

2. Hot bending

Hot bending method refers to the bending of aluminum profiles will be heated to a higher temperature before bending, through the mechanical force to make its bending.

3. Pneumatic bending method

Pneumatic bending refers to the use of air pressure to bend extruded aluminum into the desired shape. Applicable to aluminum profiles with a small bending angle.

Extruded aluminum bending process

Aluminum bending process includes: profile inspection, measurement, shearing, bending, processing and finishing.

Does seamless bending of aluminum profiles require welding?

Aluminum seamless bending does not require welding. Because the aluminum profile is the internal pressure to produce bending, no plastic deformation in the case of aluminum itself fracture, will not damage the original aluminum profile.

At the same time, the thermal expansion and contraction coefficients of aluminum profiles and welding materials are different, which can easily affect the processing accuracy and strength, and it is often difficult to meet the process requirements for welding aluminum profiles.

Summarize

Aluminum seamless bending process does not require welding, is a kind of high efficiency, energy saving, environmental protection, high precision bending method for extruded aluminum bending of various shapes, has a wide range of application prospects.

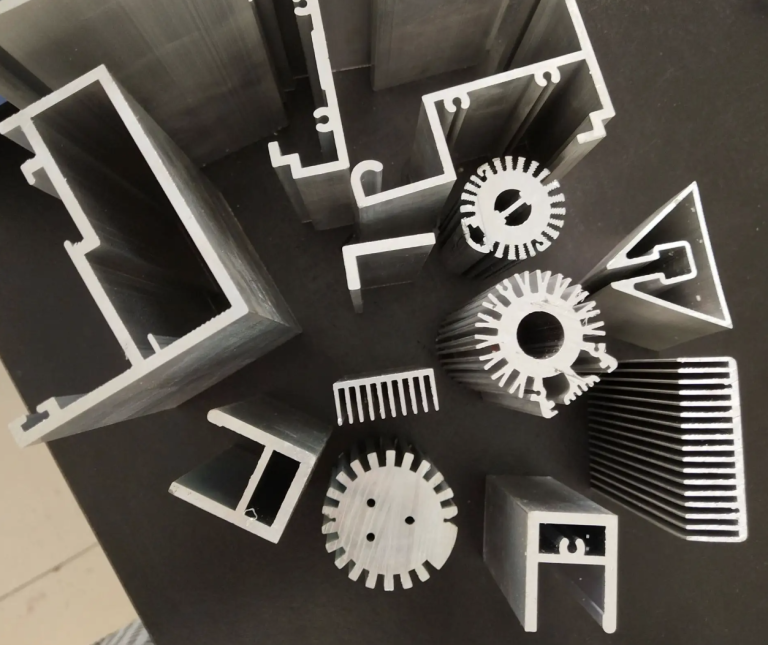

Hugh Aluminum is an aluminum extrusion manufacturer based in China. We have bending, extrusion, powder coating, anodizing, CNC and polishing processing capabilities. We are 15 years experienced aluminum extrusion supplier and can offer you factory price and high quality products.