Aluminum Profile Electrophoretic Coating

Electrophoretic Coating (E-Coating) is an advanced painting technology used for surface treatment of aluminum profiles. This process uses electric current to deposit paint uniformly onto the surface of aluminum, with excellent performance. Below is the principle and step-by-step of electrophoretic coating.

Why Choose Hugh Aluminum’s E-Coating?

Hugh Aluminum’s e-coating service is the technology and eco-friendly, high-quality, durable, and beautiful aluminum profiles for all applications.

Super Corrosion Resistance

Our e-coating creates a dense film on the surface of aluminum profiles, significantly enhancing corrosion resistance. This benefit proves invaluable for industries like construction and transportation, where materials face harsh environments.

Uniform and Smooth Coating

Our e-coating technology ensures no buildup or dripping. No matter how complex the shape of the aluminum profile, the coating adheres uniformly, resulting in a smooth surface that looks premium.

Eco-Friendly Technology

Our current e-coating process uses water-soluble paints with low VOCs, minimal environmental impact, and meets modern ecological standards. Wastewater and emissions are also reduced, and sustainable production.

Beautiful Color Effects

E-coating not only increases the protection of aluminum profiles but also offers various color options to suit different design requirements. Aluminum products look good and functional.

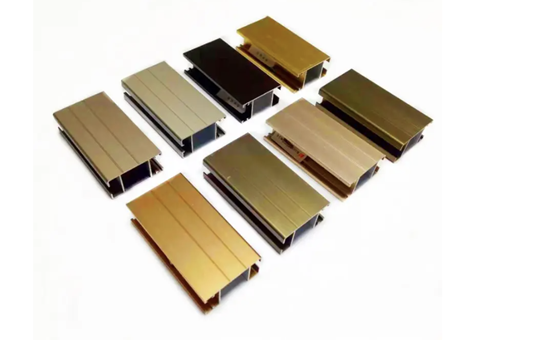

Hugh’s E-Coating Colors Chart

| Color (support customize) | Color Code (support customize) | Description |

| Black | HG 9005 | Deep, rich black finish |

| White | HG 9016 | Bright, clean white appearance |

| Silver | HG 9703 | Metallic silver finish |

| Grey | HG 7035 | Light grey for subtle finishes |

| Bronze | HG 6028 | Dark bronze with a metallic sheen |

| Blue | HG 5002 | Vivid blue, suitable for modern designs |

| Green | HG 7071 | Medium green for a natural look |

| Red | HG 3043 | Bright red for vibrant applications |

| customizable | N/A | N/A |

Principle of Electrophoretic Coating

The principle of electrophoretic coating is the movement of charged particles in an electric field to the opposite electrode and deposit on the surface of an object. Here’s how it works:

- Electric Field Action: When we disperse the coating material (usually water-soluble) in water, the particles acquire either a positive or negative charge. Under the electric field, these charged particles move toward the oppositely charged electrode.

- Deposition to Form a Coating: Once the particles reach the aluminum profile, they neutralize and deposit, forming a uniform coating. The electric field ensures the coating covers every corner of the aluminum profile, for uniformity and density.

- Curing: We then cure the coating deposited on the aluminum profile, usually through heat, to create a durable finish. This step promotes strong adhesion and enhances the coating’s longevity.

The Main Steps of E-Coating Process

The electrophoretic coating process involves the following stages:

- Pre-Treatment:

- Cleaning: We use a chemical cleaner to remove oil, dust, and oxidation from the surface of the aluminum profile, promoting better adhesion.

- Acid Etching: We apply an acid solution to eliminate surface contaminants and roughen the surface, which enhances adhesion.

- Phosphate Treatment: We apply a phosphate layer to the surface of the aluminum profile to boost adhesion and improve corrosion resistance.

- Electrophoretic Coating:

- Immersion: The cleaned aluminum profile is immersed in the coating tank where an electric field is applied. The aluminum is the anode, so it attracts negative paint particles that move toward it and deposit.

- Current Control: The current intensity and duration are controlled to ensure uniformity and the desired thickness of the coating.

- Washing and Curing:

- Rinsing: After electrophoretic coating, we rinse the aluminum profile to remove any un-deposited paint particles, ensuring a smooth surface.

- Curing: We place the coated aluminum profile in an oven for heat curing. This process typically occurs at temperatures between 160°C and 200°C for a specific duration, allowing the coating to fully cure and form a durable film.

- Quality Inspection:

- Testing: After curing, we conduct a quality check on the aluminum profiles, measuring coating thickness, adhesion strength, appearance, and corrosion resistance to confirm that each product meets quality standards.

In short, electrophoretic coating is a smart finish for aluminum profiles. It’s precise and protective. Industrial and eco-friendly.

Aluminum Profile Electrophoresis vs Other Surface Treatment Methods

The aluminum profile electrophoresis is better for corrosion and abrasion resistance than other surface treatment methods.

Better Corrosion Protection

- Electrophoresis: The coating is dense and uniform, no moisture and oxygen can penetrate. This makes aluminum profiles more corrosion-resistant, perfect for harsh environments.

- Others: Anodizing also has some corrosion protection, but not as good as electrophoresis. The anodized film can be damaged by physical impact.

Better Abrasion Resistance

- Electrophoresis: The cured coating is more wear resistant, to frequent contact or abrasion.

- Others: Anodized films are okay for wear resistance, but in high abrasion, electrophoresis has the upper hand.