How to Bend Aluminum Angle? 4 Proven Methods for Every Metalworker

Bending aluminum angles is a fundamental skill for metalworkers and DIYers. This tutorial will show you four ways to bend aluminum angles, each easy to follow and suitable for your project.

You’ll learn about simple hand tools and more advanced equipment. Each method has its benefits, so you can choose what’s best for you. We’ll give you clear, step-by-step instructions to get accurate bends without the hassle.

Whether you’re a beginner or experienced metalworker this article is for you. Learn how to bend aluminum angles and level up your metalworking skills!

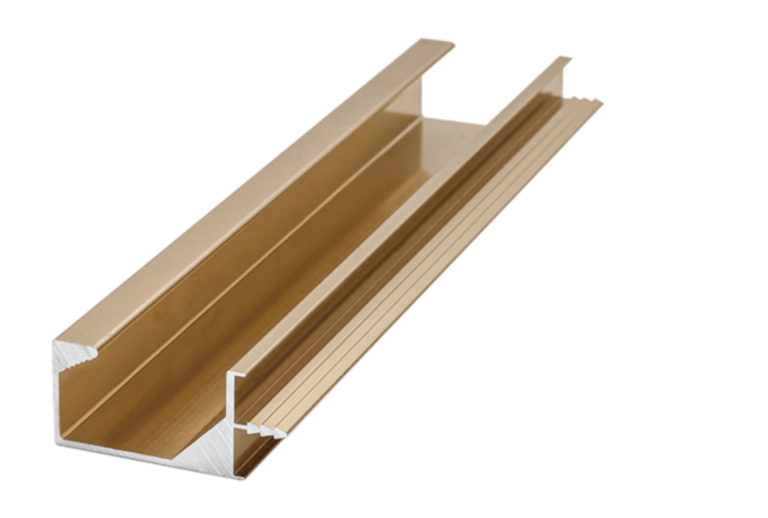

Related Product: Aluminum Angle Code

Why We Need to Bend Aluminum Angle?

Aluminum angle is a versatile material used in many projects. It works well as both a decorative element and a protective barrier in construction. If you want to create aluminum corners at different angles, bending aluminum angles into specific shapes is often necessary.

Bending aluminum is not as simple as it may seem. Aluminum alloys can be brittle. If you force the metal to bend, it may break or splinter. Nobody wants that kind of trouble!

Knowing how to bend aluminum angles correctly is important. To help you avoid damaging your materials, we’ve put together four effective methods for bending aluminum angles. These techniques will keep your projects on track and your materials safe.

Bending by Hand or with a Wrench

This method is ideal for small, simple aluminum corners. For larger pieces or bigger bends, bending by hand can be challenging. Here’s how to bend aluminum corners manually or with a wrench.

Tools You’ll Need

- Wrenches

- Angle rulers

- Gauges

- Equipment to secure the aluminum corner

Steps to Bend Aluminum Angle

- Measure the Angle: Use an angle ruler and gauge to measure the length of the aluminum angle and the angle you want to achieve.

- Secure the Aluminum: Place the aluminum angle on a sturdy tabletop. Fasten it securely to prevent it from moving while you work.

- Apply Pressure: Use your hands or a wrench to apply pressure along the marked angle. A wrench can help you exert more force if needed.

- Check Your Work: After bending, use the angle ruler to confirm that the corner is at the desired angle. Make adjustments if necessary.

Bending aluminum can feel like wrestling a stubborn mule, but with the right tools and technique, you can do it! This method is straightforward and effective for smaller projects. Now, let’s explore other techniques that might work better for your needs.

Bending Aluminum Angle by Heating

Aluminum softens when heated. This property makes it easier to bend. However, heating aluminum requires caution and proper equipment.

Safety First

Heating aluminum to its melting point is dangerous. This task is not safe for home use. You need specialized tools and safety gear.

Heating Process

- Prepare the Aluminum: Place the aluminum angle in a heating device. Heat it to the right temperature based on the alloy type and thickness.

- Monitor the Temperature: Use a thermometer to keep track of the heat. Avoid overheating, as this can melt the aluminum or damage its properties.

- Bend the Aluminum: Once the aluminum softens, use a hot bender or specialized tools to bend it. The softened metal allows for better control of the bending force and angle.

- Cool Down: After bending, let the aluminum cool to room temperature. Check your work and make any adjustments as needed.

Get Professional Help

For safety, consider working with an aluminum manufacturer or fabricator. They have the right equipment and expertise for safe bending. Hugh Aluminum offers 1200 tons of bending and processing equipment for aluminum extrusions and angles.

Bending aluminum with heat can be effective if done correctly. Prioritize safety and precision for the best results!

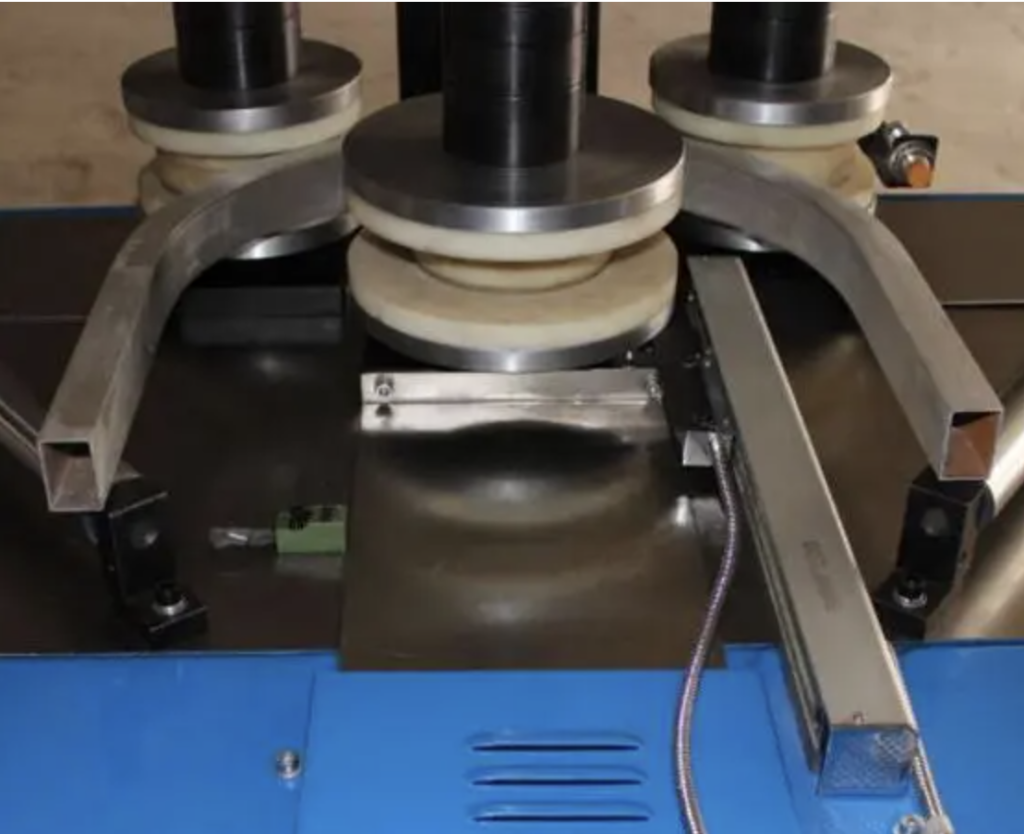

Bending with Pull-Bending Machine

What is a Pull Bending Machine?

A pull-bending machine is a tool that bends metal into specific shapes. It uses several parts, including the main body, slider, guide rail, and fixture, to do this effectively.

How It Works

- Fixture Fixation: The machine holds the metal securely in place. This prevents any movement or deformation during bending.

- Slider Movement: The slider moves along the guide rail. This action drives the fixture and the metal together.

- Bending and Molding: As the slider moves, it bends the metal at a set position and angle, creating the desired shape.

Important Considerations

Using a pull-bending machine is effective for aluminum angles, but it can leave marks from the jaws on both sides of the metal. Additionally, harder aluminum alloys like 7075 or 2024 may break under stress. Be cautious when bending these materials to avoid fractures.

A pull-bending machine can provide precise results. However, if you want high-quality bends without damage, consider professional services or specialized equipment for the best outcome.

Bending Aluminum Angles by Welding

This method does not typically involve bending aluminum corners directly. Instead, you create a curve by welding two cut aluminum angles together.

Preparation Steps

- Cut the Aluminum: Cut two or more aluminum angles at different angles. A 45-degree cut along the cross-section simplifies the welding process.

- Pre-Treat the Cuts: Clean the welding area on each cut. Remove any oxidized layers and debris to promote a strong bond during welding.

Related product: Aluminum 90-Degree Angle Extrusions

Welding Considerations

- Select the Right Method: Use welding techniques suitable for aluminum, such as TIG or MIG welding.

- Control Key Parameters: Monitor welding temperature, speed, and current. Keeping these factors in check is essential for good weld quality.

Welding aluminum angles is an effective way to create curves when bending is not an option. With proper preparation and the right equipment, you can achieve strong and clean joints. Get ready to shape those angles with confidence!

What is the Best Way to Bend Aluminum Angle?

The best method for bending aluminum angles depends on a few key factors. These include the thickness of the aluminum, the tools available, and the angle you need.

If you are comfortable with your tools, you can bend aluminum yourself using a wrench. However, a bending machine is often the better option. It provides precise angles and is ideal if you are unsure about bending aluminum manually.

Hugh Aluminum manufactures aluminum angles and can help with the design and processing of all types of aluminum. If you want to buy aluminum angles in bulk or need a reliable supplier, we are here to assist you.