How can I extend the life of my aluminium extrusions?

Want to extend the life of your aluminium extrusions. Make it last longer or increase its frequency of use.

We can take the following specific measures:

1. Material selection:

Choose high quality aluminium extrusions. High quality ensures sufficient strength and oxidation resistance. Choose Hugh Aluminium’s aluminium extrusion products, the service life can reach 10-15 years.

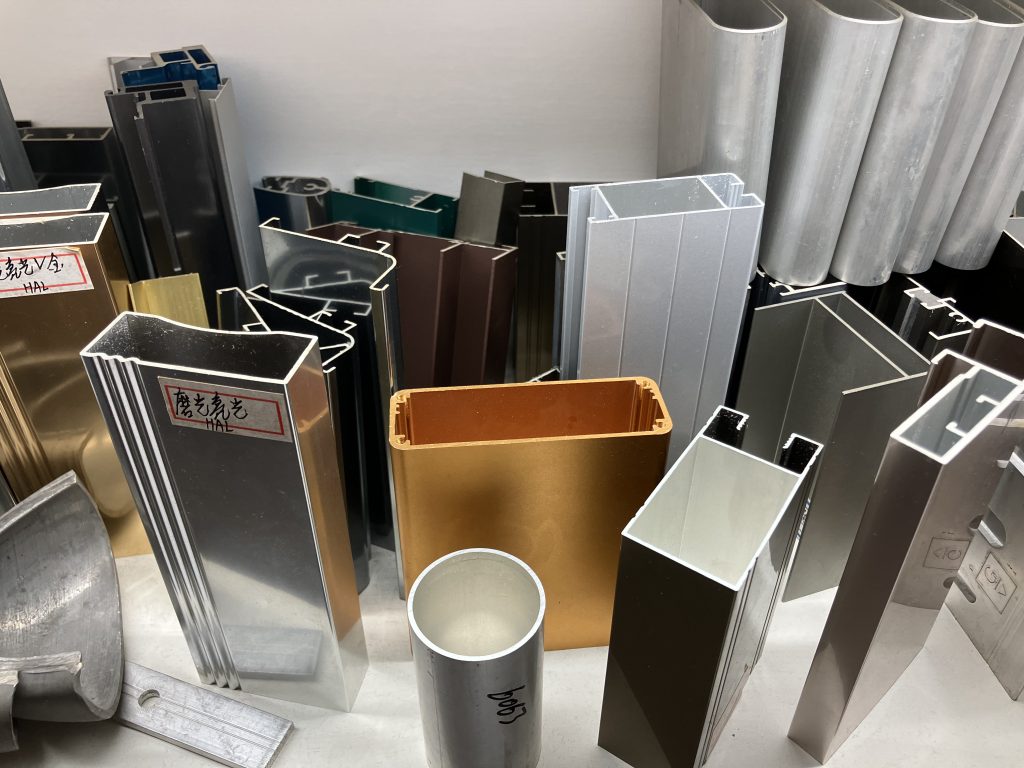

2. Surface treatment of aluminium extrusion:

We can treat the surface of aluminium extrusions appropriately. For example, anodic electrophoresis, powder coating and so on. It can improve the corrosion resistance and surface hardness. The life span of aluminium products which have received surface treatment can be increased by 20-40%.

3. Usage:

Use aluminium profiles reasonably to avoid fatigue damage caused by overuse or improper use. Avoid excessive impact or extrusion of aluminium profiles during installation and use. For example, slamming aluminium doors and windows.

4. Maintenance:

We can clean the aluminium extrusions regularly by using neutral cleaners to remove surface stains and dust.

Keep it dry and ventilated, avoid long-term exposure to humid environment.

For parts that need lubrication, add lubricant regularly to reduce friction and wear. Reasonable maintenance can increase its service life.

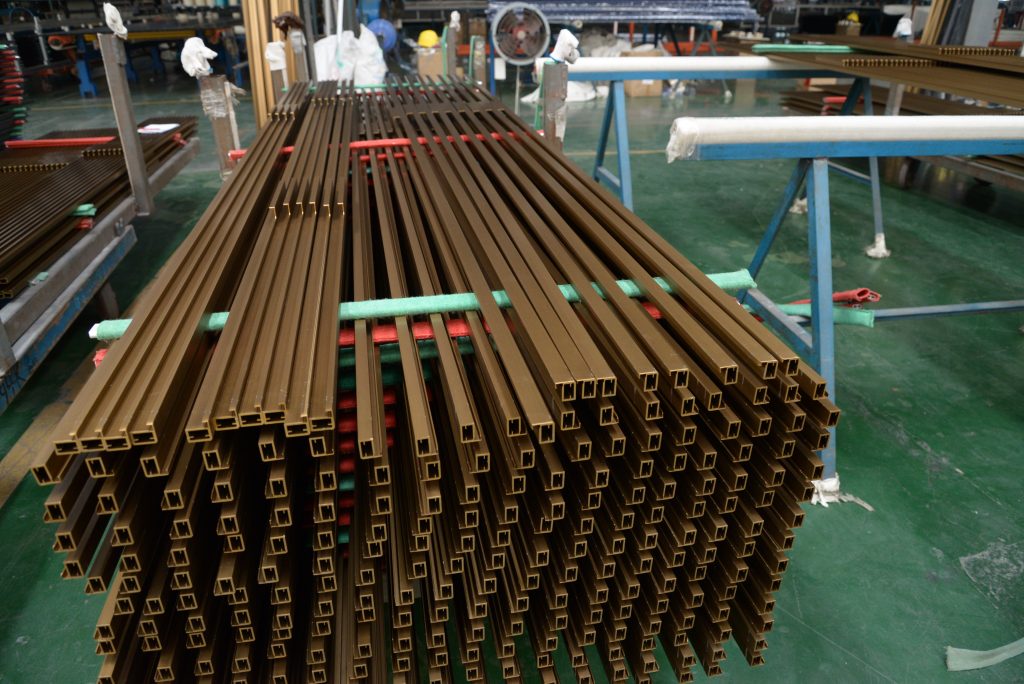

5. Storage and transport:

During transportation, aluminium profiles must be held lightly. Avoid bumping and scratching in transport.

The storage environment should be dry, bright and well ventilated. Avoid storing with chemical materials and humid materials.

6. Design of aluminium products:

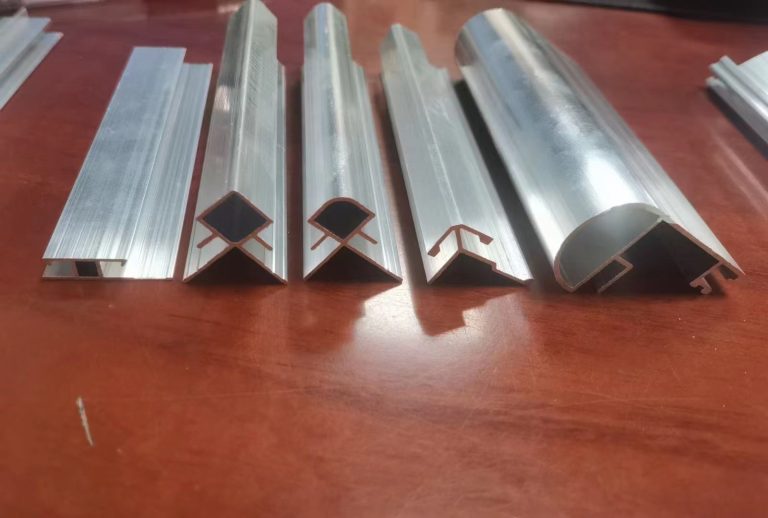

When designing aluminium profiles products, consider human convenience and safety. Avoid reducing the wall thickness at the position of high pressure.

We have to choose suitable cross-section shapes and sizes to ensure that the aluminium profile has sufficient load-bearing capacity.

7. Regular inspection and replacement:

We should test the extrusion products regularly to find and deal with potential problems in time. This can avoid the shortening of service life.

For the damaged parts that have already appeared, we should repair or replace them in time.

By taking the above specific measures, we can not only effectively extend the service life of aluminium extrusion. And it also improves its stability and reliability.

Hugh Aluminium is an aluminium extrusion plant. We offer a design to production service.

We have 14 years of production experience and have served over 600 customers from forty countries.

If you want to purchase aluminium extrusion products in bulk or looking for a good supplier.

Please contact us!