How long does Aluminum Extrusion Last?

The life of an aluminum extrusion depends on a number of factors. These include the environment in which it is used, the pressure or load to which it is subjected, the surface treatment (e.g. anodized, painted, etc.), maintenance, the type of alloy, and the quality of manufacture.

Regular Use Period:

Generally speaking, if aluminum profiles are used in a normal indoor environment . . and is not subjected to excessive physical or chemical damage, it can last for decades or longer.

Aluminum is a corrosion-resistant light metal with excellent resistance to oxidation and weathering, which gives it a long service life in many applications.

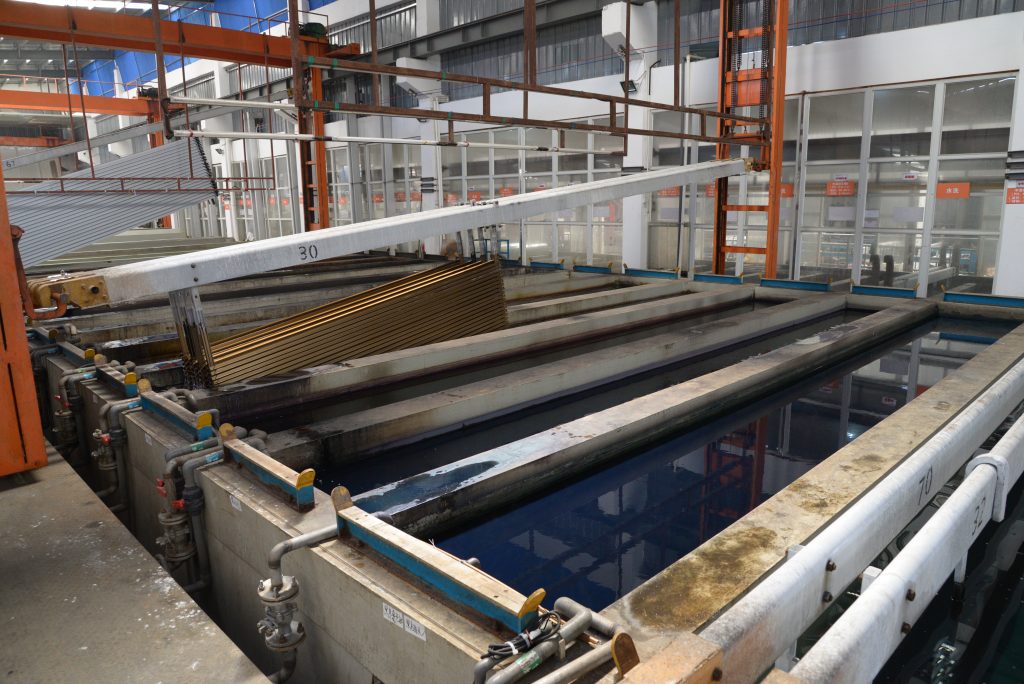

After surface finishing treatment:

Extruded aluminum after finishing (powder coating, anodizing) is able to maintain the same appearance in the face. Its service life can reach more than 15 years.

Surface-treated aluminum profiles can be used in outdoor environments. It can face the complex environment and keep the appearance unchanged.

So generally the aluminum products we use can be used outdoors for a long time after surface treatment. We don’t need to worry about its appearance.

Factors affecting the life of aluminum extrusions:

1.Material quality:

The quality of raw materials directly affects their service life. High-quality aluminum extrusion, such as the use of virgin aluminum ingot production of aluminum profiles, its service life is longer, generally up to 20-30 years, or even more than 40 years.

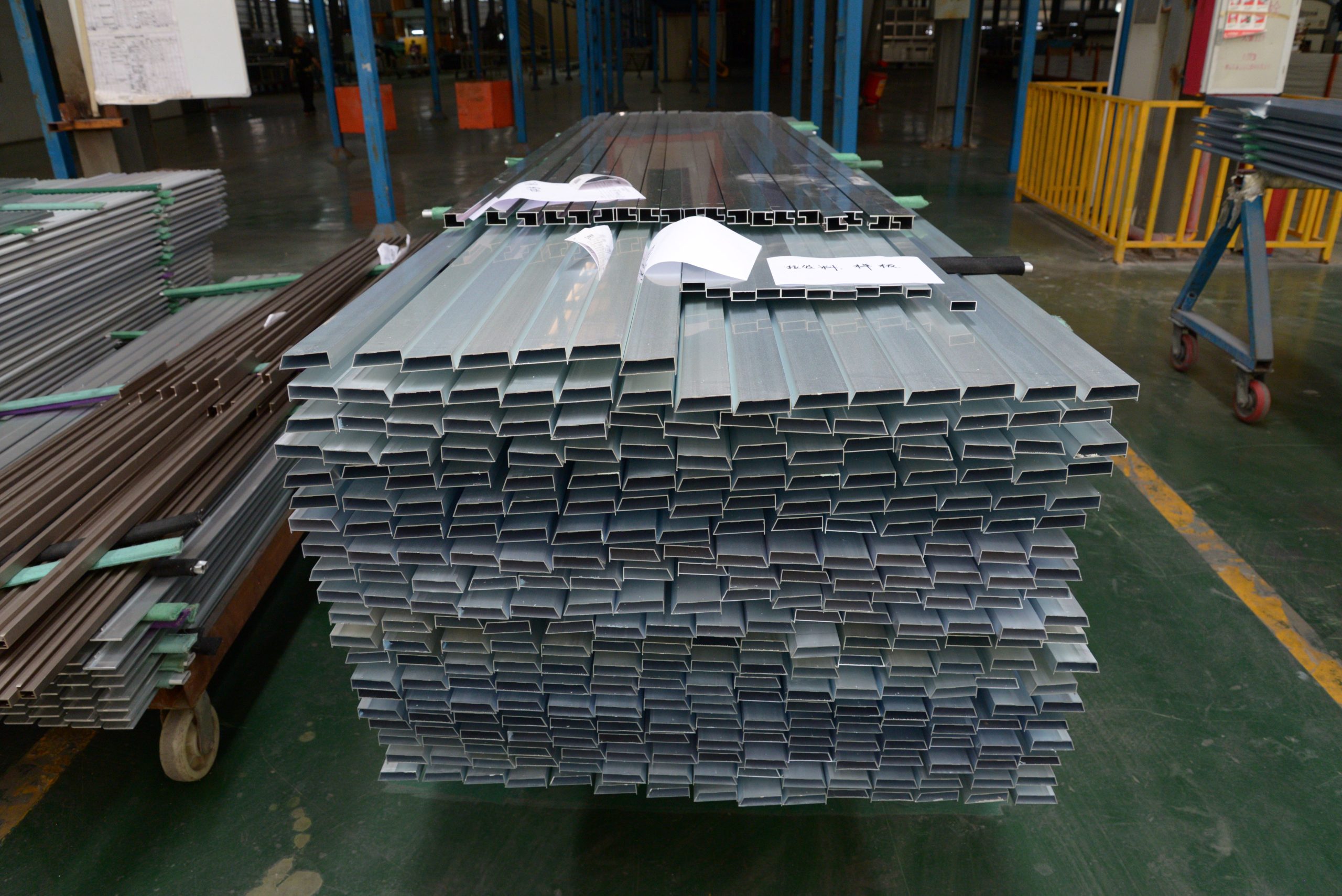

2. Production process:

The steps and techniques of the production process also affect the service life of aluminum profiles. For example, the precision of the aluminum extrusion die does not meet the quality requirements, which may lead to a decline in sealing performance, which in turn affects the service life of aluminum profiles.

3. Local climatic conditions:

Climatic conditions in different regions can have a significant impact on the life of extruded aluminum. For example, wet, rainy or corrosive gas content of the region, the corrosion rate of aluminum will be accelerated, thus shortening its life.

4. Frequency of maintenance and upkeep:

Regular maintenance is also an important means of extending the life of aluminum profiles. For example, the sealing performance of aluminum extrusions and the condition of coatings should be checked regularly so that potential problems can be detected and dealt with in a timely manner. Cleaning its surface at a frequency of twice a year and reasonable maintenance can extend the life of aluminum.

In order to extend the service life of aluminum profiles, the following measures can be taken:

1. Select an aluminum profile alloy and surface treatment suitable for the environment in which it is to be used. If it needs to be installed in harsh environments a hard oxidized surface process is required.

2. avoid excessive physical damage to the aluminum extrusion during installation and use. Examples include scratches and cosmetic damage caused by impact.

3. Regularly maintain and care for aluminum extrusions. For example, cleaning, checking the condition of the coating, etc. We can choose to sand or paint to protect the exterior coating when it is peeling off.

4. Replace damaged aluminum components when needed. For example, damaged aluminum connectors or damaged corner yards. We need to replace them.

In summary

Generally speaking, the life of aluminum profiles will be longer. We need to evaluate its service life according to the specific use environment and conditions.

Hugh Aluminum is an aluminum extrusion plant based in China. We have extrusion, powder coating, anodizing, CNC and polishing processing capabilities. We are 15 years experienced aluminum extrusion supplier and can offer you factory price and high quality products.