How much does Aluminum Extrusion Cost?

Are you facing challenges with aluminum extrusion prices for your construction project? If your budget falls short, predicting costs can help. But how much do aluminum extrusions actually cost? What factors influence their market price?

This article will explore the factors that affect the cost of aluminum extrusions. Understanding these factors will prepare you for how aluminum products can impact your budget. Whether you need a specific aluminum profile, a different alloy grade, or a special finish, knowing the costs involved is essential.

Key Factors Affecting Aluminum Extrusion Prices

Understanding the factors that influence aluminum extrusion prices is essential for budgeting your project. Here are the main elements that affect costs:

1. Die and Tooling Costs

Die and tooling costs significantly impact aluminum extrusion pricing. The cost of the aluminum profile mold is spread across the mass production of profile products. If you produce more than 10 tons, the mold cost may be waived.

2. Aluminum Prices

Current aluminum prices fluctuate based on market conditions. You can check the London Metal Exchange for daily ingot prices. These prices directly affect the overall cost of aluminum extrusions.

3. Labor Costs

Labor costs vary depending on the complexity of the extrusion process and the skill level required. Skilled workers are needed for tasks such as designing dies, ordering aluminum, and creating extrusions.

4. Further Processing Costs

Additional processing, such as cutting, machining, or bending, adds to the overall cost. Each step requires labor and resources, which impacts your budget.

5. Surface Finishing Costs

Surface finishing improves the appearance and durability of extrusions. Common finishes include anodizing and powder coating, and their costs can vary based on the desired effect.

6. Logistics Costs

Transportation costs are generally fixed expenses but can vary based on distance and shipping methods. Efficient logistics planning can help manage these costs.

7. Production Volume

The volume of your order affects pricing significantly. Higher production volumes typically lead to lower per-unit costs due to shared die and tooling expenses.

By considering these factors, you can better estimate aluminum extrusion costs and manage your project budget effectively.

Read more: The aluminum extrusions industry costs and profitability.

Aluminum Extrusion Price Calculation Formula

To calculate the final price of aluminum extrusion, use this formula:

Die Costs (large quantities may be waived) + Current Aluminum Prices + Labor Costs + Production Costs + Finishing Costs (plus any additional processing costs if needed) + Shipping Costs = Final Price of Aluminum Extrusion

This formula helps estimate aluminum extrusion prices. Key factors can change based on operational conditions and market trends. For example, labor costs, packaging costs, and die costs can vary. If you have a long-term order or meet the required quantity, you may waive die costs.

Important Notes:

- Die Costs: The cost of aluminum profile molds depends on specifications, mold structure complexity, and production requirements. Typically, die costs range from $400 to $7,000. As the quantity of profiles increases and you reach a certain order volume, the cost per unit for the mold decreases.

- Flexibility: Companies often adjust labor and processing fees based on their needs and market conditions.

By understanding this formula and its components, you can better estimate your aluminum extrusion costs and plan your budget effectively.

Aluminum Price in 2025

The price of primary aluminum depends on several factors, including global demand, industry trends, and electricity costs. You can estimate the base price of aluminum using exchanges like the London Metal Exchange.

Aluminum prices have fluctuated significantly in recent years. Paying a large deposit upfront can sometimes lock in a lower price. In 2019-2020, the average price of aluminum ingots ranged from $2,500 to $3,000 per tonne, with a peak at $3,080 per tonne in 2020. Ordering aluminum at these lower prices can help you save money.

Different grades of aluminum have different costs. Manufacturers may not stock certain special grades. For example, choosing grades like 6082 or 7075 will increase your costs.

Current Trends for 2025

Forecasts indicate that aluminum prices may rise by about 6% in 2025 due to strong global demand outpacing supply. Analysts predict that the average price will reach approximately $2,450 per tonne. This increase is driven by growing demand from sectors such as clean energy in China, the largest consumer of aluminum.

Understanding these factors helps you make informed decisions about your aluminum extrusion projects and manage your budget effectively.

Why Does the Price of Aluminum Fluctuate?

The price of aluminum can change due to several factors, including geopolitical events and market conditions. For instance, the Russian-Ukrainian war in 2023 affected aluminum prices because both countries are major producers. The conflict disrupted mining operations, leading to higher prices.

Stricter environmental regulations in the U.S. have also limited operations in the electrolytic aluminum industry. These regulations contribute to rising aluminum prices.

Additional Factors Influencing Aluminum Prices:

- Global Demand: Increased demand from industries like automotive and construction can raise prices.

- Production Costs: Changes in energy prices and labor costs can impact overall production expenses.

- Market Speculation: Traders’ expectations about future supply and demand can lead to price fluctuations.

How Much Do Extrusion Die Costs?

The cost of aluminum extrusion dies typically ranges from $400 to $2,000. These dies usually have diameters between 60 mm and 178 mm, keeping prices relatively low. However, if the outer diameter exceeds 200 mm, costs can rise significantly, ranging from $2,300 to $10,000. The final price depends on the complexity of the aluminum profile.

If you have already paid for the mold, the typical lead time for production is 2 to 3 weeks. If you order in large quantities—generally over 15 tons—the aluminum extrusion factory may refund the cost of die manufacturing.

What Factors Affect the Cost of Extrusion Dies?

- Types of Extrusion Dies: Prices can vary based on whether you need a flat die or a shunt die.

- Size of Aluminum Extrusion: Larger dies usually cost more.

- Complexity of Profile Cross-Section: More complex profiles require intricate dies, which increases costs.

- Precision Requirements: Higher precision demands can raise the price.

- Lead Time: Urgent orders may incur additional charges.

Price of Labor and Production

The cost of labor and processing in aluminum extrusion is easier to predict than the costs of complex molds and fluctuating raw materials. You can use local wage levels for a reliable estimate.

Factors Affecting Processing Costs

Several factors influence processing costs:

- Equipment Purchase Price: The initial investment in machinery impacts overall costs.

- Maintenance Costs: Regular maintenance of equipment adds to expenses.

- Utilities: Energy and water costs contribute to production expenses.

- Personnel Operating Costs: Wages and benefits for workers are significant factors.

- Worker Productivity: The efficiency of workers affects production costs.

Labor costs in Europe and America are generally higher than in Asia and Africa. However, production levels and product quality are also important. Spending less on low-quality aluminum extrusions can lead to wasted time and resources.

Choosing an aluminum extrusion manufacturer that balances quality with lower labor costs can lead to good prices. For example, Hugh Aluminum is a Chinese manufacturer that follows the ISO 9001 quality management system. We offer affordable, high-quality aluminum extrusion products.

Aluminum Finishing and Further Processing Costs

After the extrusion process, you can apply surface finishing and additional processing to improve the extruded part. These processes enhance appearance, increase protection, and add functionality. Here are common machining processes for aluminum extrusion:

Surface Finishing Processes

- Powder Coating: This method applies a durable powder to the aluminum surface. The powder fuses during curing, creating a strong finish that resists scratches and wear.

- Anodizing: This electrochemical process thickens the natural oxide layer on aluminum. Anodized surfaces resist corrosion and can be colored.

- Electrophoretic Coating: This technique uses an electric current to deposit a uniform layer of paint on the aluminum surface.

- PVDF (Polyvinylidene Fluoride): This coating offers excellent weather resistance, making it ideal for outdoor applications.

- Polished or Mill Finish: A polished finish gives aluminum a shiny look, while a mill finish retains the raw appearance of the material.

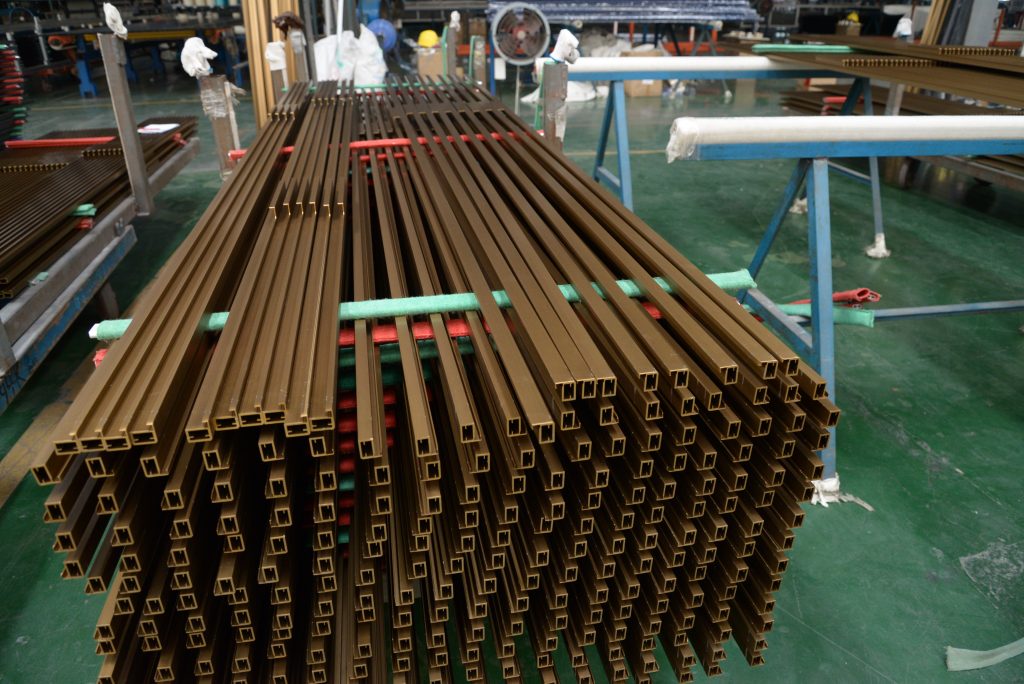

- Wood Grain Finish: This process transfers a wood-like pattern onto the aluminum surface, providing an attractive alternative to traditional finishes.

Choosing the right finishing options can improve both the aesthetic appeal and durability of your aluminum extrusions, helping you meet your project requirements effectively.

What Will the Surface Finishing Cost?

Powder coating is the most common aluminum finishing method. It costs between $1,300 and $1,800 per ton. Anodizing is a cheaper option, with prices ranging from $800 to $1,400 per ton.

For specialized finishes like PVDF or wood grain, expect to pay over $2,700 per ton. The exact cost varies based on the size of the aluminum extrusion.

You know these costs and can budget for your aluminum extrusion. Choose the right finish and you can get the look and durability you want and save.

What Is the Cost of Deep Processing?

The cost of deep processing for aluminum extrusions varies based on the complexity of the process and the equipment needed. Simple drilling operations typically cost between $200 and $300 per ton. In contrast, complex welding and CNC machining that require high precision can range from $900 to $2,100 per ton.

Common Deep Processing Methods

Aluminum extrusion deep processing includes several methods:

- CNC Machining: This method uses computer-controlled tools for precise shaping and cutting.

- Drilling: This process creates holes in aluminum at a lower cost.

- Stamping: This method shapes aluminum by applying pressure to form specific designs.

- Welding: This technique joins pieces of aluminum using heat or pressure.

- Bending: This process shapes aluminum into curves or angles.

- Cutting: This method reduces the size of aluminum pieces to meet specifications.

- Tempering or Aging: This process strengthens aluminum through heat treatment.

You can budget for your aluminum extrusion with clear cost in mind. Choose the right process and you can get the quality and functionality you need for your product.

Logistics Pricing and Tax

Logistics costs greatly affect the total price of aluminum extrusion. The COVID-19 pandemic showed how rising logistics expenses can impact businesses. At the height of the pandemic, shipping a container sometimes cost more than a luxury car, highlighting the importance of these costs for consumers.

Key Considerations for Logistics Costs

- Shipping Costs: In 2023, shipping a 40HQ container from Asia to North America ranged from $7,600 to $14,300. This cost varies based on the shipping company’s routes and distances. Choosing the most affordable shipping option can help you stay within budget.

- Local Tariffs: Import tariffs can increase costs when bringing products from abroad to your market. For example, U.S. trade tariffs on Chinese goods can add to shipping expenses. Researching government websites for current tariff rates is essential to secure lower costs and maintain profitability.

Other Factors That Can Affect Price

Competition among aluminum extrusion manufacturers drives changes in production processes to lower costs and improve product competitiveness. This competition increases the factors that influence the price of aluminum profiles.

Key Influencing Factors

- Raw Materials: Manufacturers can choose between primary and recycled aluminum. Using recycled aluminum from secondary melting can reduce raw material costs, affecting the price of extruded profiles.

- Production Processes: Simplifying production steps can lower costs. For example, skipping processes like sandblasting can decrease overall production expenses.

Example of Cost Calculation

To understand how to calculate the price of extruded aluminum, consider this example:

- Aluminum Ingot Price: $6,500 per ton

- Processing Fees: $4,000 (includes labor, finishing fees, and equipment losses)

- Die Setup Costs: $2,000

- Packaging Costs: Included in the overall weight of aluminum profiles (assuming one ton)

The total cost per ton of aluminum profiles is calculated as follows:

Total Price=Aluminum Material Cost+Processing Fee+Die Cost

Total Price=6,500+4,000+2,000=12,500 per ton

This calculation shows how various factors contribute to the final price of aluminum extrusions. Understanding these elements helps you budget effectively for your projects.

Final Thoughts

The total cost of manufacturing custom aluminum extrusions depends on various factors. Some factors, like tooling prices and labor costs, are easy to predict. Others, such as shipping costs, can be harder to estimate.

Hugh Aluminum offers competitive prices for aluminum extrusions and profiles to help you capture your local market quickly. Our team is ready to assist you! Our experts can guide you from design to manufacturing. Contact us today for support!