How much does it cost to start an Aluminum Extrusion Plant?

Launching an aluminum extrusion plant can be a good opportunity but you have to know the costs. This article outlines the expenses you will face when launching a medium-sized facility, including construction, equipment, and operational costs.

By breaking down these financials, we will give you a clear picture of what it takes to get into the aluminum extrusion industry.

Total Investment for a Medium Aluminum Extrusion Plant

To establish a medium-sized aluminum extrusion plant, the total investment ranges from about $20 million to $30 million. This amount covers essential expenses, including plant construction, equipment purchases, raw material inventory, employee recruitment, and working capital. Each of these costs plays a vital role in launching and operating a successful aluminum extrusion facility.

Read more: The aluminum extrusions industry costs and profitability.

What to Invest in When Starting an Aluminum Extrusion Plant?

When starting an aluminum extrusion plant you need to invest in several areas. Plant construction, equipment, raw material inventory, employee recruitment, and operating capital. Knowing these investment components will help you plan and succeed in your new business as explained below.

Plant Construction

Building an aluminum extrusion plant costs between $2 million and $4 million. This amount covers land purchase, construction, and equipment installation.

Equipment Purchase

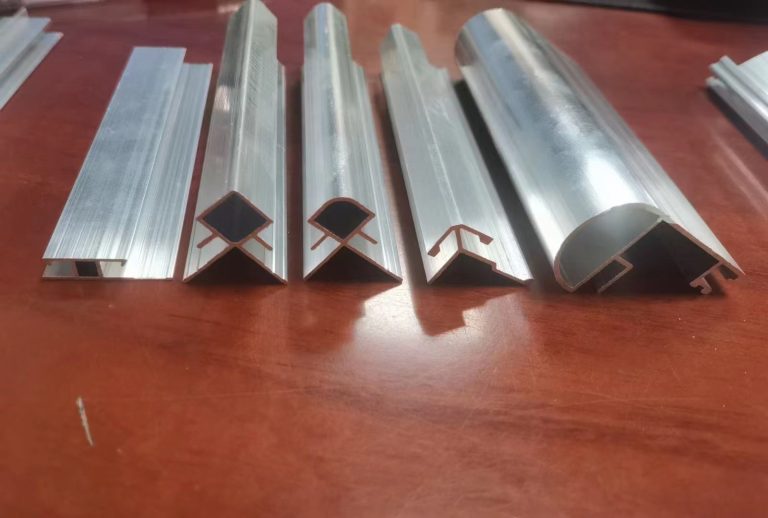

Aluminum extrusion plants need large machines like extruders, coating lines, and preheating machines. Equipment costs vary by brand and model, typically ranging from $2 million to $3 million.

Raw Material Inventory

Plants require a significant amount of raw materials for production and surface treatment. The investment in raw material inventory ranges from $1 million to $2 million, depending on market prices and production needs.

Employee Recruitment

Factories must hire extrusion operators, painting operators, anodizing operators, and other technicians. Recruitment costs, including wages and training, range from $500,000 to $1 million.

Operating Capital

Factories incur various operational costs such as utilities, maintenance, and depreciation. These expenses vary based on production scale and typically require an investment of $1 million to $2 million.

Other Expenses

In addition to the direct costs mentioned earlier, consider several other expenses. These include costs for environmental protection equipment, transportation, and taxes. Each of these factors can increase overall expenses and affect the financial performance of an aluminum extrusion business. It is essential to account for these additional costs when evaluating profitability and planning your budget.

It is essential for anyone considering investment in the aluminum extrusion industry. Each expense contributes to the overall financial picture and impacts potential profitability.

Final Thoughts

Starting an aluminum profile factory involves careful consideration of various costs. The total investment typically ranges from $20 million to $30 million. This estimate can vary based on specific project details and local market conditions. Understanding these financial factors is essential for anyone interested in entering the aluminum extrusion industry.