How strong is aluminum extrusion?

As an extruded aluminum manufacturer. We know exactly how strong it is? If you click in and want a quick answer. My answer is that the strength of extruded aluminum is “very strong”.

Why do I give this answer? Because the strength of an aluminum extrusion will depend on many factors. For example, the strength of aluminum. Yield strength is the minimum stress value of a material when yielding occurs, that is, the stress value at which the material begins to produce significant plastic deformation when subjected to external force.

Yield strength of extruded aluminum: The yield strength of extruded aluminum profiles varies depending on the material, generally between 100-150MPa

We will start by looking at the following factors:

- Strength Factors

- Material grade and properties

- Influence of extrusion process

- Influence of cross-section shape

- Structural applications of extruded aluminum

Strength Factor of aluminum extrusion

The “strength” of aluminum is usually referred to as the compressive strength of extruded aluminum.

The compressive strength of extruded aluminum varies depending on the alloy type, heat treatment state, and extrusion process. Generally speaking, high-strength and high-hardness aluminum alloy extrusions will have higher compressive strength.

It should be noted that aluminum alloys are generally more commonly used in applications that require good tensile properties and corrosion resistance rather than in applications that directly withstand high pressure. Therefore, specific data on the compressive strength of extruded aluminum may not be as common as tensile strength or yield strength.

Material Grade and Characteristics

1. Alloying Elements and Content

The strength of aluminum extrusions depends first on their alloy composition. Strength comes from the added alloying elements. The most commonly used are silicon, iron, copper, magnesium, manganese and chromium. For example, the widely used 6000 series aluminum alloy contains a lot of silicon and magnesium. Therefore, the 6000 series alloy is a corrosion-resistant, lightweight material with medium to high strength

It is worth noting that:

Some aluminum alloys can further improve their strength during heat treatment. For example, heat-treated aluminum profiles (such as 6061, 7075, etc.) will have significantly improved strength after quenching and aging. Some low-strength aluminum profiles (such as 1xxx series, 3A21, etc.) do not require or are not suitable for heat treatment strengthening.

This video shows aluminum extrusion processing:

2. Influence of aluminum Extrusion Process

1. Extrusion Temperature

Extrusion temperature is an important factor affecting the strength of aluminum profiles. At the appropriate temperature, aluminum alloy materials have better plasticity and deformability, which is conducive to the extrusion process.

However, too high a temperature may cause the material to be too soft, increase the difficulty of extrusion and affect the strength and hardness of the final product. Therefore, controlling the extrusion temperature is one of the key steps to improve the strength of aluminum extrusions.

2. Extrusion speed

Extrusion speed is also an important factor affecting the strength of extruded aluminums. Too slow an extrusion speed may increase the difficulty of extrusion and make it impossible to extrude evenly.

Excessive extrusion speed may cause problems such as increased internal stress and cracks in the aluminum material. Therefore, choosing a suitable extrusion speed is crucial to ensure the strength and quality of aluminum extrusions.

3. Die design

The design of the die not only affects the shape and size of the aluminum extrusion, but also directly affects the stress distribution and deformation during its extrusion process. A properly designed die can reduce stress concentration and damage during aluminum extrusion, thereby improving the strength and overall performance of aluminum extrusions.

3. Influence of extruded aluminum cross-sectional shape

1. Cross-sectional shape design

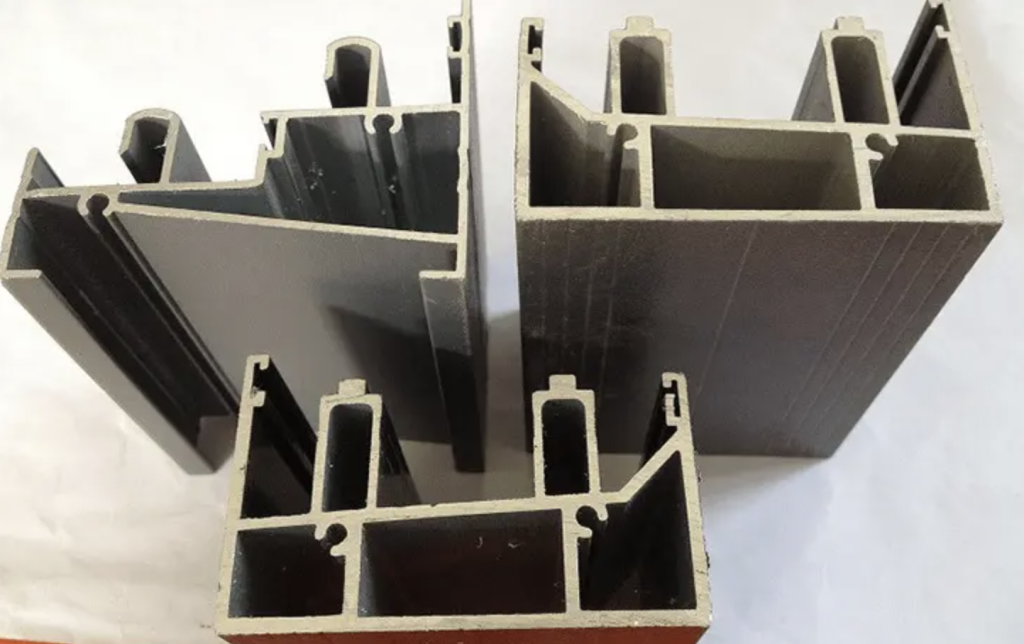

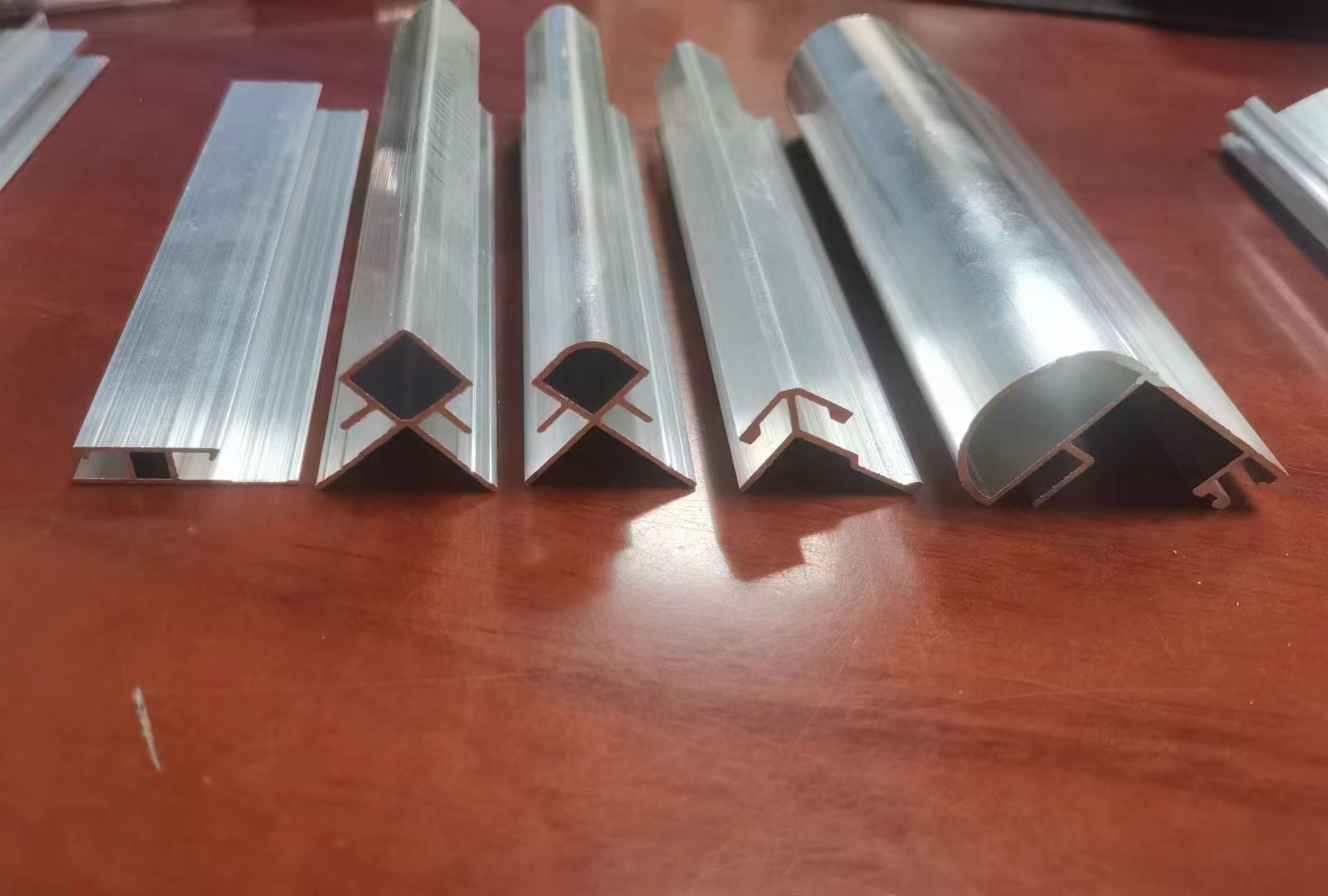

The cross-sectional shape of aluminum profiles has an important influence on their strength. For example, it is necessary to avoid designing cross-sections with sharp corners to reduce stress concentration; at the same time, the wall thickness should be uniform to avoid uneven performance due to different flow rates. In addition, reasonable cross-sectional shape design can also improve the bearing capacity and stability of aluminum extrusions.

2. Cross-sectional size tolerance

Control of cross-sectional size tolerance is crucial to ensure the strength and performance consistency of aluminum extrusions. Tolerance setting should be considered comprehensively based on factors such as product processing allowance, usage conditions, and extrusion difficulty. Too large tolerances may lead to unstable product performance; while too small tolerances may increase processing difficulty and cost.

4. Structural application of aluminum extrusion

Due to the advantages of light weight, high strength, good corrosion resistance, and easy processing and forming, aluminum extrusions have been widely used in construction, transportation, electronics, aerospace and other fields.

For example, in the field of construction, aluminium extrusions can be used to make window frames, door frames, curtain wall panels, etc.

In the field of transportation, they can be used to manufacture body structural parts, wheels and other components. These applications not only give play to the excellent performance of aluminum extrusions, but also meet the needs of various industries for lightweight and high strength.

The right aluminum extrusion helps your project succeed

Whether the strength of aluminum extrusion can meet the needs of the project depends on your budget. Because its strength lies in the aluminum alloy and grade, the size of the cross section and the wall thickness of the product. These factors all depend on the budget of the project. If your budget is higher, aluminum extrusion will be a better material than steel.

Hugh Aluminum is a manufacturer of Aluminium U Channel. We design and manufacture all types of U Channel.

If you need to purchase U Channel in bulk or looking for aluminium suppliers?

Please contact us! We have 14 years of manufacturing experience and served more than 600+ customers from 40+ countries. Our team is friendly and professional.

Please contact us!