How to Choose Aluminum Extrusion Square Tubes?

Choosing the right extruded aluminum square tube requires careful consideration of several factors. Here are the key steps to guide your selection:

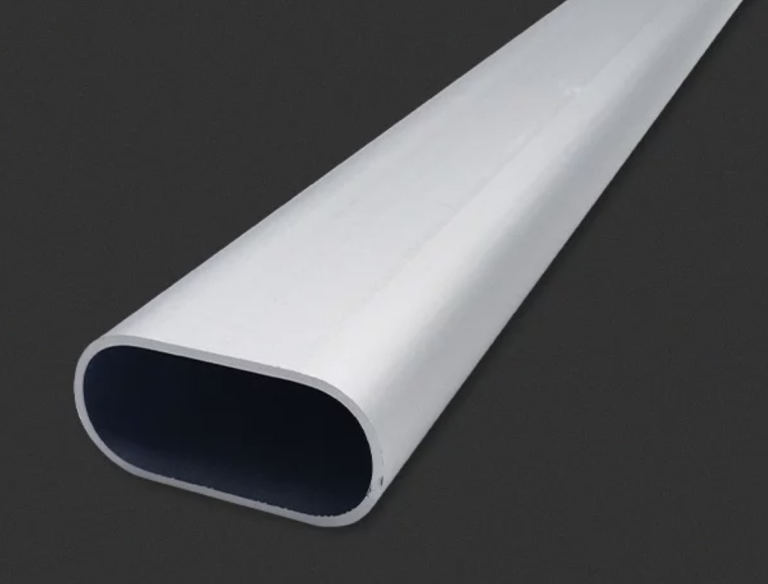

More products: Aluminum tube extrusions

Material Selection

Aluminum square tubes come in two main types:

- Pure Aluminum: Offers excellent corrosion resistance and thermal conductivity. It is suitable for specific environments, such as marine or chemical settings.

- Aluminum Alloys: Provides greater strength and hardness. Common alloys like 6061 and 6063 are ideal for applications that require higher pressure resistance.

Size and Thickness

Select the size and wall thickness based on your project’s needs. These factors directly impact the tube’s load-bearing capacity and durability.

- For example, a 2.0mm wall thickness offers better resistance to external impacts compared to thinner options.

Surface Treatment

Choose a surface treatment that fits the intended use:

- Anodizing: Increases corrosion resistance and adds an attractive finish.

- Powder Coating: Provides extra protection and allows for color customization.

Production Process

The production process affects the quality of aluminum square tubes. Key steps include raw material preparation, extrusion, cooling, cutting, shaping, and surface finishing. Proper control of pressure and temperature during extrusion ensures accurate dimensions and smooth surfaces.

Brand and Quality

Select a reputable brand known for quality products. Look for certifications like ISO standards to confirm compliance with industry regulations, ensuring reliable performance over time.

Cost and Budget

Evaluate cost in relation to quality by considering price-performance ratios. While aluminum may be more expensive than materials like steel, its benefits can justify the investment in certain projects.

Use Environment and Requirements

Consider the environment where the tube will be used:

- Temperature: Aluminum may deform under prolonged exposure to high heat, so account for this in your design plans if necessary.

- Humidity or Corrosive Conditions: Pure aluminum or anodized surfaces perform well in these environments.

Summary

When choosing extruded aluminum square tubes, assess material type, size, surface treatment, production quality, brand reputation, cost, and environmental factors. By evaluating these aspects carefully, you can select the best option that meets your project’s needs while staying within budget.

Read more: Aluminum Tubes Applications Overview