How to Connect Aluminum Round Tubes?Techniques and Insights

Aluminum round tubes are widely used for transporting energy and as building materials. Their numerous advantages make them suitable for various automotive, industrial, construction, and medical applications.

If you have chosen aluminum round tubes for your project but are unsure how to connect them, this article will help you. You will learn about the methods and tools needed for connections and the underlying principles. By following these guidelines, you can connect different aluminum round tube types and sizes.

How to Join Aluminum Tubes with Connectors?

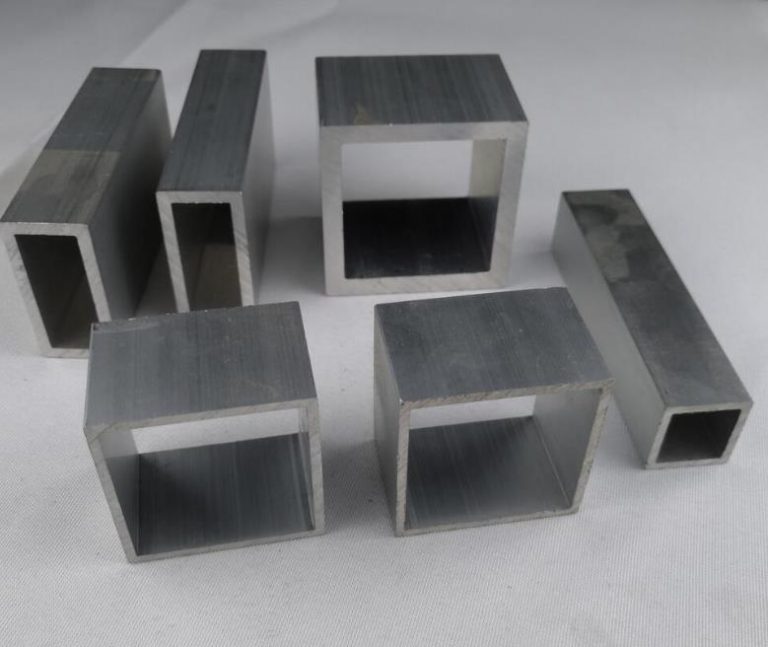

Tube connectors are a simple and effective way to join aluminum round tubes. They also work with square and rectangular tubes. Most connectors are made from strong nylon, making them lightweight and easy to use. You can find various styles and sizes at your local hardware store.

How do Tube Connectors Work?

Tube connectors join two or more sections of aluminum tubing by inserting plugs into their ends. This creates a secure connection for corners, right angles, or pipe ends.

Required Tools

To connect aluminum extruded tubes, gather these tools:

- Aluminum tube connector

- Gauze or polishing machine

- Cutting machine or hacksaw

- Measuring tape and pen

Steps to Join Aluminum Round Tubing

- Cut the Aluminum Tube: Use a cutter or hacksaw to cut the tube to your desired length.

- Mark the Cut Position: Before cutting, mark the position with a red or black pen to avoid mistakes.

- Saw the Tube: Secure the tube while cutting to prevent slipping. Make sure the connector width matches the tube.

- Deburr the Edges: Smooth sharp edges using coarse gauze or a polisher.

- Insert into Connector: Push both tube extrusions into the connector ends by hand until they fit snugly. If needed, use a rubber mallet for a tighter fit.

- Repeat as Needed: Continue adding tubes and connectors until your frame is complete. Some connectors may need hot melt adhesive for extra stability, so follow any instructions provided.

By following these steps, you can easily connect aluminum round tubes and create strong structures that meet your needs.

It is important to note that some connectors require hot melt adhesive to hold the tube profile in place, so we should follow the instructions for selling aluminum tube connectors.

How to Join Aluminum Tubes by Welding?

Welding is a practical method for connecting large extruded tubes or when suitable connectors are unavailable. This process can be complex and poses safety risks, as soldering can cause burns.

Tools Needed for Welding

To weld aluminum tubes, gather these tools:

- Argon arc welding torch or liquefied gas welding torch

- Organic solvents like acetone or gasoline for cleaning

- Wire brush and polishing agent

- Welding wire and pads (e.g., graphite or stainless steel)

- Heating furnace for preheating aluminum extrusion tubes

- Thermometer

Steps for Welding Aluminum Tubes

- Clean the Surface: Remove oxide film and oil from the aluminum tubes and welding wire using chemical or mechanical cleaning methods.

- Design the Joints: Create a joint design based on the tube sizes. Keep the gap between joint sides within 0.08 to 0.2 mm, and limit the weld seam length to 30 mm.

- Preheat the Tubes: For thicker tubes (10 mm to 15 mm), preheat them to 100°C to 200°C. This step helps prevent deformation and porosity.

- Weld the Ends: Ignite the welding torch and adjust the flame to evenly heat the welding area. Melt the ends of the aluminum tubes until they fuse.

- Polish After Welding: After welding, polish the aluminum extruded tube to smooth any uneven surfaces from the weld. This reduces friction and improves strength.

Important Considerations

When choosing a connection method, consider material, specifications, environment, and connection needs. Always prioritize safety during this process. If you are unsure about welding, consult a professional for help.

Welding can effectively connect aluminum extruded tubes if done correctly. With proper preparation and care, you can create strong joints that meet your project requirements.

Hugh Aluminum Joins Aluminum Tubing

Hugh Aluminum has a skilled welding team with 14 years of experience. We specialize in welding and can assist you with your projects.

As a large aluminum extrusion manufacturer, we meet all your needs. We handle everything from design to production of various aluminum tubes. Whether you need welded or extruded tubes, our team is ready to help.

Let us simplify your aluminum tubing connections! We are here to make the process smooth and efficient.