How to Curve Aluminum? The Ultimate Guide to Techniques and Tips

Curving aluminum is essential for projects ranging from DIY crafts to automotive repairs and artistic designs. With the right techniques, you can achieve smooth, precise bends that enhance your work’s functionality and aesthetics. This guide outlines practical methods for bending aluminum, explains the tools required, and provides actionable tips to help you succeed.

Why Curving Aluminum Matters?

Aluminum is a versatile material used in countless applications due to its lightweight, durable nature. Learning how to bend it correctly allows you to:

- Create customized parts for machinery or vehicles.

- Design intricate shapes for sculptures or architectural features.

- Improve project durability by maintaining structural integrity during bending.

Whether you’re shaping tubes, sheets, or plates, understanding the process ensures professional results without compromising the material’s strength.

Read more: How to bend aluminum tubes?

Understanding the Basics of Aluminum Bending

Aluminum bending is a vital skill in metalworking, valued for its versatility in projects ranging from simple DIY tasks to advanced industrial applications. Understanding why aluminum is ideal for bending and how to work with it safely is key to achieving successful results.

Why Aluminum Is Ideal for Bending?

Aluminum’s unique properties make it a preferred material for bending:

- Lightweight and Easy to Handle: Aluminum is significantly lighter than metals like steel, making it easier to manipulate and transport.

- Highly Malleable: It bends smoothly without requiring excessive force or advanced tools, even for beginners.

- Corrosion-Resistant: Aluminum naturally resists rust, ensuring durability in outdoor or humid environments.

- Temperature Resilience: It withstands both high and low temperatures, making it suitable for applications like automotive parts or heat exchangers.

These qualities make aluminum an excellent choice for projects where flexibility, durability, and ease of use are essential.

Safety Tips for Bending Aluminum

Before bending aluminum, prioritize safety by following these steps:

- Wear Protective Gear: Use gloves to prevent cuts, goggles to shield your eyes, and flame-resistant clothing if heat is involved.

- Prepare Your Workspace: Work in a well-lit, ventilated area to reduce risks from fumes or poor visibility.

- Inspect Tools and Materials: Ensure your tools (e.g., bending jigs, clamps) are in good condition and appropriate for the task.

- Start Slowly: Apply gradual pressure when bending to avoid damaging the material or causing accidents.

Safety preparation not only prevents injuries but also ensures smoother project execution.

Key Takeaways

- Aluminum’s lightweight, malleable, and corrosion-resistant properties make it ideal for bending projects of all sizes.

- Always prioritize safety by wearing protective gear, preparing your workspace, and using tools correctly.

- Start with small projects to build confidence and refine your techniques before tackling complex designs.

By mastering these basics, you’ll be prepared to bend aluminum effectively while ensuring safety and quality in every project.

READ MORE: How to bend aluminum flat bar?

Tools You Need for Bending Aluminum

To bend aluminum effectively, you need reliable tools that deliver precision and consistency. Below is a breakdown of essential equipment, along with actionable tips to help you achieve professional results.

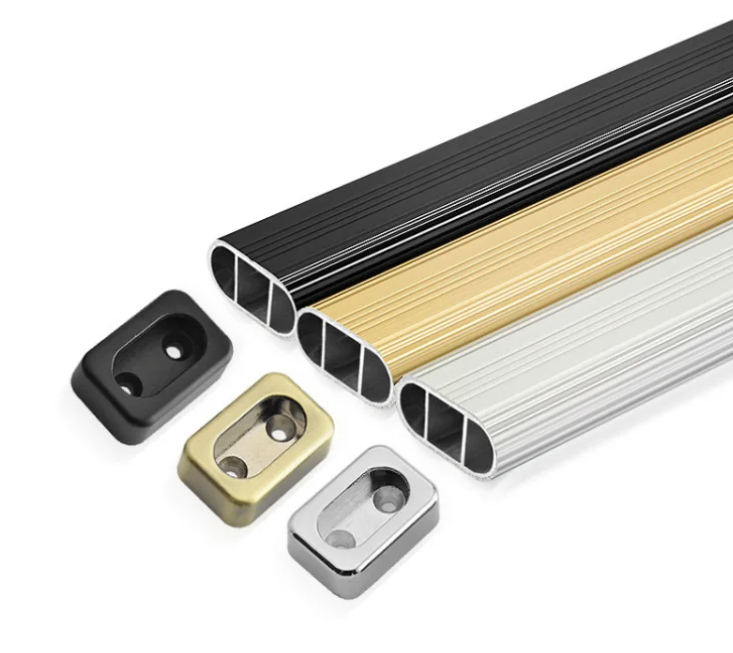

Tube Benders: Essential for Aluminum Tubing

Tube benders are designed to shape aluminum tubing into smooth curves without crimping or flattening the material. These tools are ideal for projects like plumbing systems, furniture frames, or automotive components.

Tips for Using Tube Benders Effectively:

- Match Specifications: Choose a bender that fits the diameter and wall thickness of your tubing.

- Practice First: Test on scrap aluminum to refine your technique before working on your final project.

- Avoid Overbending: Gradually curve the tubing to prevent damage or distortion.

Sheet Metal Brakes: Precision for Aluminum Sheets

Sheet metal brakes are perfect for creating long, straight bends in aluminum sheets. They provide control and accuracy, making them essential for projects such as metal panels, enclosures, or decorative trims.

How to Maximize Results with Sheet Metal Brakes:

- Check Capacity: Ensure the brake can handle the width and thickness of your sheet.

- Secure Properly: Clamp the sheet tightly to prevent movement during bending.

- Work Slowly: Apply consistent pressure to achieve clean, sharp bends.

DIY Bending Jigs: Cost-Effective for Repetitive Tasks

DIY bending jigs are custom-built tools that simplify repetitive bends. By designing a jig tailored to your specific angles and dimensions, you can ensure consistent results across multiple pieces.

Benefits of DIY Bending Jigs:

- Save Time: Perfect for batch projects requiring identical bends.

- Customize Easily: Use materials like wood or steel to create jigs suited to your needs.

- Improve Accuracy: Reduce errors by standardizing your bending process.

Additional Tips for Success

- Safety First: Always wear gloves and protective eyewear when working with aluminum.

- Measure Twice: Double-check dimensions before bending to avoid costly mistakes.

- Stay Organized: Keep tools and materials neatly arranged for efficient workflow.

By using these tools and techniques, you can bend aluminum with precision and confidence. Whether you’re working on small DIY projects or large-scale fabrications, investing in the right equipment will ensure high-quality results every time.

Read more: How to bend aluminum angles?

How to Curve Aluminium: Common Techniques?

Learning how to bend aluminum effectively can help you create precise, durable components for a wide range of projects. Below are three proven techniques explained clearly and concisely to help you achieve professional results.

Heat Bending: Precision with Controlled Heat

Heat bending is ideal for shaping thick or large aluminum pieces. By applying heat evenly, the metal becomes pliable, making it easier to create smooth curves. This method is especially useful when cold bending is impractical due to the material’s rigidity.

Steps for Heat Bending:

- Prepare the Surface: Clean the aluminum and mark the bending line clearly.

- Apply Heat: Use a heat gun or torch to warm the marked area evenly. Avoid overheating, as it can weaken the metal.

- Shape Gradually: Bend the aluminum slowly as it softens, using tools like clamps or jigs for precision.

- Cool Naturally: Let the metal cool at room temperature to maintain its strength.

Best Use Case: Heat bending is perfect for creating curved frames or structural components that require durability and accuracy.

Cold Bending: Simple and Effective for Thin Sheets

Cold bending works well for thinner aluminum sheets or smaller projects. This technique uses steady pressure at room temperature to shape the metal without heating tools, making it accessible and beginner-friendly.

Steps for Cold Bending:

- Choose a Tool: Use a bending brake or vise to apply consistent pressure.

- Mark Your Bend Line: Measure carefully and mark where you want the bend for precise results.

- Bend Slowly: Apply gradual pressure to avoid kinks or cracks in the aluminum.

Best Use Case: Cold bending is ideal for crafting brackets, channels, or decorative accents where simplicity is key.

Using a Bending Brake: Clean and Accurate Results

A bending brake is essential for creating sharp, uniform bends in aluminum sheets. It clamps the material securely and applies controlled force, ensuring clean lines and consistent angles across longer sections of metal.

Steps for Using a Bending Brake:

- Secure the Setup: Mount the brake firmly and clamp your aluminum tightly to prevent movement during bending.

- Check Angles: Use an angle finder to verify bends as you work.

- Practice First: Test on scrap pieces before working on your final project to refine your technique.

Best Use Case: A bending brake is perfect for making enclosures, frames, or other components that require straight edges and professional finishes.

Final Tips for Aluminum Bending

- Choose the technique based on your project’s material thickness and complexity.

- Practice on scrap aluminum before starting your main project to avoid mistakes.

- Use proper safety equipment, such as gloves and goggles, when working with heat or tools.

By mastering these techniques, you’ll gain confidence in shaping aluminum for various applications—from functional parts to creative designs.

How to Curve Aluminum: Advanced Bending Techniques

Mastering advanced aluminum bending techniques allows you to take on more intricate and demanding projects. These methods improve precision, expand your capabilities, and deliver professional results.

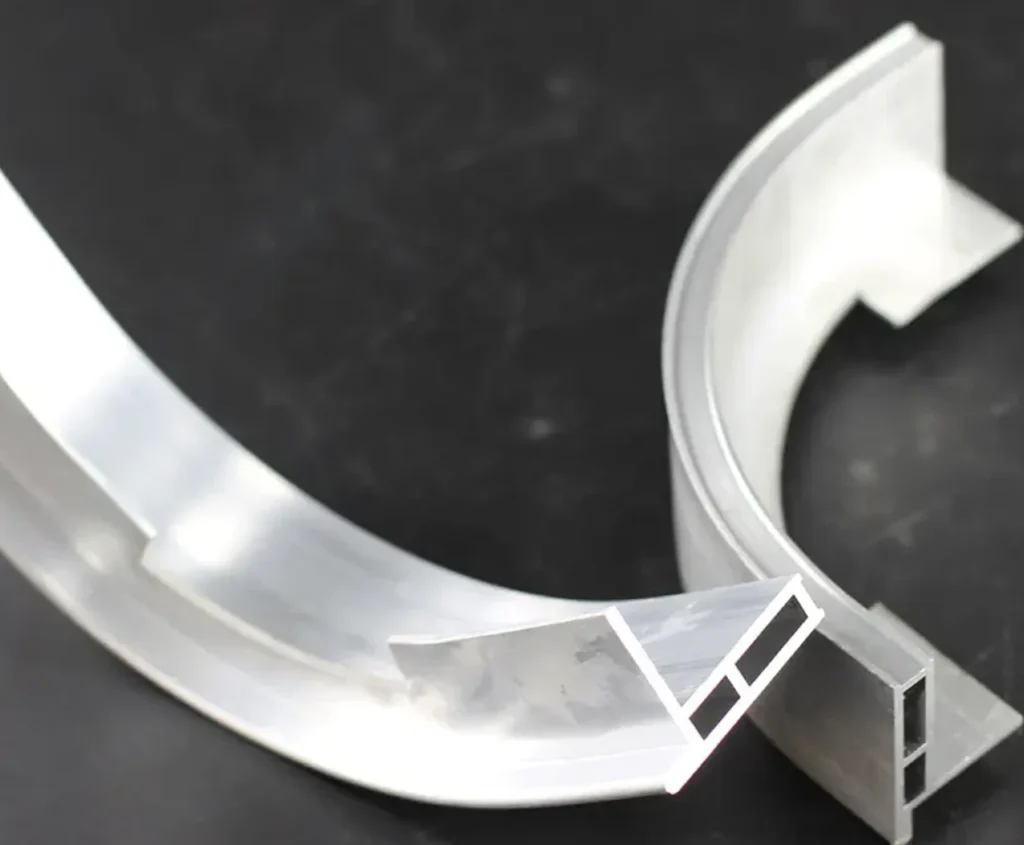

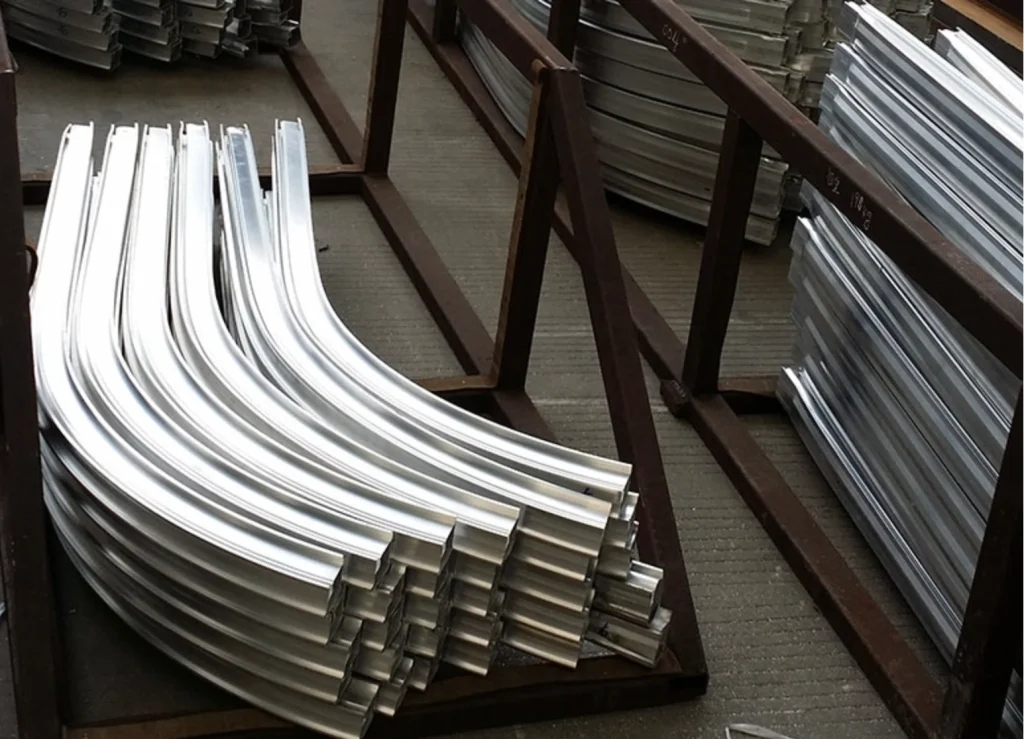

Creating Complex Shapes with Aluminum

Shaping aluminum into intricate designs requires careful planning and the right tools. Whether for decorative or functional purposes, success depends on understanding how aluminum behaves under stress.

Steps to Shape Aluminum:

- Plan Your Design: Use detailed blueprints or CAD software to map out your project.

- Segment the Curve: Divide complex shapes into smaller, manageable sections.

- Use Form Blocks: Create custom molds to guide the aluminum into the desired shape.

- Make Gradual Adjustments: Bend incrementally to maintain accuracy and avoid over-stressing the metal.

Example: For a curved aluminum handrail, breaking the design into smaller arcs and using form blocks ensures smooth, precise results.

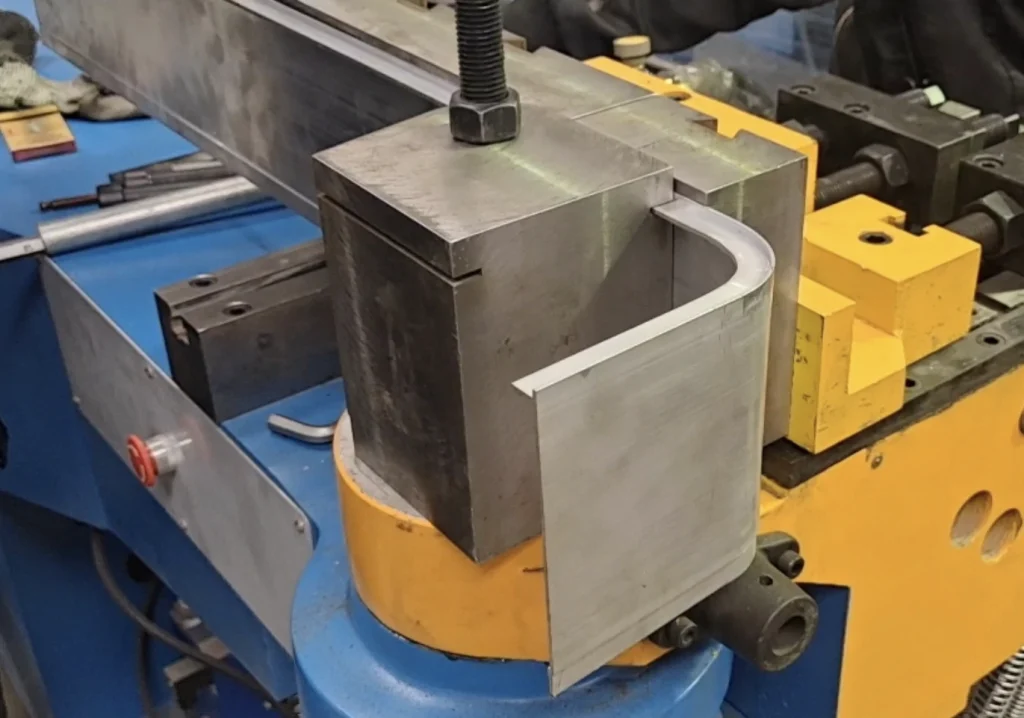

Bending Thick Aluminum Plates

Thick aluminum plates are harder to bend due to their rigidity. However, with proper techniques and tools, you can achieve clean bends without damaging the material.

Effective Methods:

- Preheat the Plate: Apply heat to soften the aluminum and reduce cracking risks.

- Bend in Increments: Apply gradual force instead of a single large bend to distribute stress evenly.

- Use Heavy-Duty Tools: Opt for hydraulic press brakes or plate bending machines designed for thick materials.

Tip: When bending structural beams, preheating combined with incremental bending ensures strength and precision.

Using Anvil Bending for Sharp Angles

Anvil bending is ideal for creating sharp, precise angles in aluminum. This technique is best suited for smaller projects requiring high accuracy.

Steps for Anvil Bending:

- Select the Right Anvil: Choose an anvil with a sharp edge matching your desired angle.

- Optional Heat Application: Heat the aluminum slightly if it’s too rigid for easy bending.

- Hammer Carefully: Use a mallet or hammer to bend the aluminum over the anvil’s edge. Apply steady force to avoid uneven bends.

Analogy: Think of anvil bending like folding paper along a straight edge—it requires precision and care to achieve clean results.

Expanding Your Aluminum Bending Skills

Advanced techniques like shaping complex curves, bending thick plates, and creating sharp angles allow you to handle more challenging projects. With practice and patience, these methods will help you produce high-quality designs tailored to your needs.

Ask Yourself: What project could benefit from these techniques? Whether you’re crafting architectural elements or custom metalwork, these methods can bring your vision to life.

Common Mistakes and How to Avoid Them

Bending aluminum requires precision and care. Mistakes can lead to structural issues or damaged materials. Here’s a breakdown of common errors and actionable ways to avoid them.

Overbending: Causes and Solutions

Overbending occurs when aluminum is bent beyond the desired angle, weakening its structure or rendering it unusable. To prevent this:

- Use Precision Tools: Employ an angle finder or protractor to measure bends accurately and avoid exceeding your target angle.

- Work Gradually: Bend the aluminum in small increments, checking progress frequently to maintain control.

- Test on Scrap Material: Practice on leftover aluminum pieces to refine your technique before working on the final piece.

Approaching the process with patience ensures you achieve clean, precise bends without compromising the material’s integrity.

Avoiding Cracks and Breaks

Cracks or breaks often occur when aluminum is bent cold or subjected to excessive force. Prevent these issues with the following steps:

- Apply Heat for Thicker Pieces: Use a heat gun or torch to warm thicker aluminum sections before bending. Heat increases flexibility and reduces the risk of cracking.

- Increase Pressure Gradually: When bending cold aluminum, apply steady, incremental force to avoid overstressing the metal.

- Choose the Right Alloy: Select aluminum alloys suited for bending, such as 5052-H32, which is more malleable than harder alloys like 6061-T6.

By treating aluminum carefully—like softening butter with gentle heat—you can achieve smooth bends without damaging the material.

Additional Tips for Successful Bending

- Inspect Materials Before Starting: Check for scratches or weak spots that could lead to failure during bending.

- Account for Springback: Aluminum often returns slightly toward its original shape after bending. Plan for this by over-bending slightly but not excessively.

- Use Proper Equipment: Tools like bending brakes or pipe benders provide consistent results and reduce manual errors.

These strategies will help you avoid common pitfalls and produce high-quality bends every time. What challenges have you faced while working with aluminum? Share your experiences—we’re here to help troubleshoot.

Projects and Applications for Bent Aluminum

Automotive Applications

Bent aluminum is essential in automotive manufacturing, providing strength and efficiency for components like chassis, frames, and exhaust systems. Its lightweight nature reduces vehicle weight, improving fuel efficiency and performance. Precise bending methods, such as mandrel or rotary draw bending, are critical to meeting the strict tolerances required for these parts. For example:

- Chassis and Frames: Aluminum’s durability and low weight make it ideal for supporting vehicle structures while enhancing speed and handling.

- Exhaust Systems: Custom-bent aluminum pipes optimize airflow, boosting engine performance.

By mastering these techniques, manufacturers can create reliable, high-performing automotive components that meet industry standards.

Home DIY Projects

Aluminum’s adaptability makes it perfect for DIY home projects. Its corrosion resistance ensures long-lasting results, while its malleability allows for creative designs. Here are some practical applications:

- Garden Furniture: Build lightweight chairs, tables, or benches that withstand outdoor conditions.

- Custom Shelving: Craft sleek, modern shelves tailored to fit your space.

- Decorative Pieces: Create artistic sculptures or frames to personalize your home decor.

With basic tools like tube benders or heat-assisted shaping techniques, even beginners can transform aluminum into functional and stylish creations. Whether designing furniture or crafting decor, aluminum offers endless possibilities for home improvement projects.

Final Thoughts

Curving aluminum requires practice and precision. By starting with small, manageable projects, you can build your skills and gradually take on more advanced tasks. Focus on mastering basic techniques before exploring complex designs, such as curved panels for furniture or automotive applications.