How to Get Different Colors for Aluminium Extrusions?

Manufacturers offer aluminum extrusions in many colors and finishes, which makes them versatile for various uses. But how do they add these colors?

The process is simpler than you might think. Hugh Aluminium will walk you through the methods used to add color to aluminum extrusions, step by step.

What Is Anodising and How Does It Add Color to Aluminum?

Anodizing is an electrochemical process that forms an oxide layer on aluminum. This layer protects the metal from corrosion and increases its hardness.

The process colors aluminum in various shades, including black, gold, bronze, and brown.

Manufacturers immerse the aluminum in a dye solution, where the dye molecules bond with the oxide layer to create a durable and vibrant finish.

How Does Powder Coating Add Color and Protection to Aluminum?

Powder coating involves applying a dry powder to aluminum extrusions using an electrostatic charge. The powder sticks to the surface, and the process heats it to create a durable finish.

This process produces a hard coating that resists scratches and corrosion. Powder coating also allows for a wide range of colors, including white, black, gray, bright shades, and metallic textures. It’s an effective way to customize the appearance of aluminum extrusions while adding protection.

Why Choose Fluorocarbon Coating for Outdoor Aluminum Extrusions?

Fluorocarbon coating applies a layer of fluorocarbon resin to aluminum extrusions. This coating protects the surface and improves durability.

It is highly resistant to weather, corrosion, and chemicals. Its self-cleaning properties make it especially suitable for outdoor use.

Fluorocarbon coating also provides a wide range of color options. From soft, muted tones to bright, bold shades, it offers long-lasting and attractive finishes.

How Does the Wood Grain Transfer Process Transform Aluminum?

Wood grain transfer gives aluminum profiles the look and texture of natural wood. This process creates a durable and realistic wood-grain finish on the surface.

The method involves printing a wood grain pattern onto transfer paper. The paper is applied to the aluminum extrusion, and heat and pressure are used to transfer the design. The result is a long-lasting wood-like appearance.

This technique combines the aesthetic appeal of wood with the strength and durability of aluminum, making it a practical and stylish choice.

How Does Anodic Electrophoresis Create Durable and Colored Coatings on Aluminum?

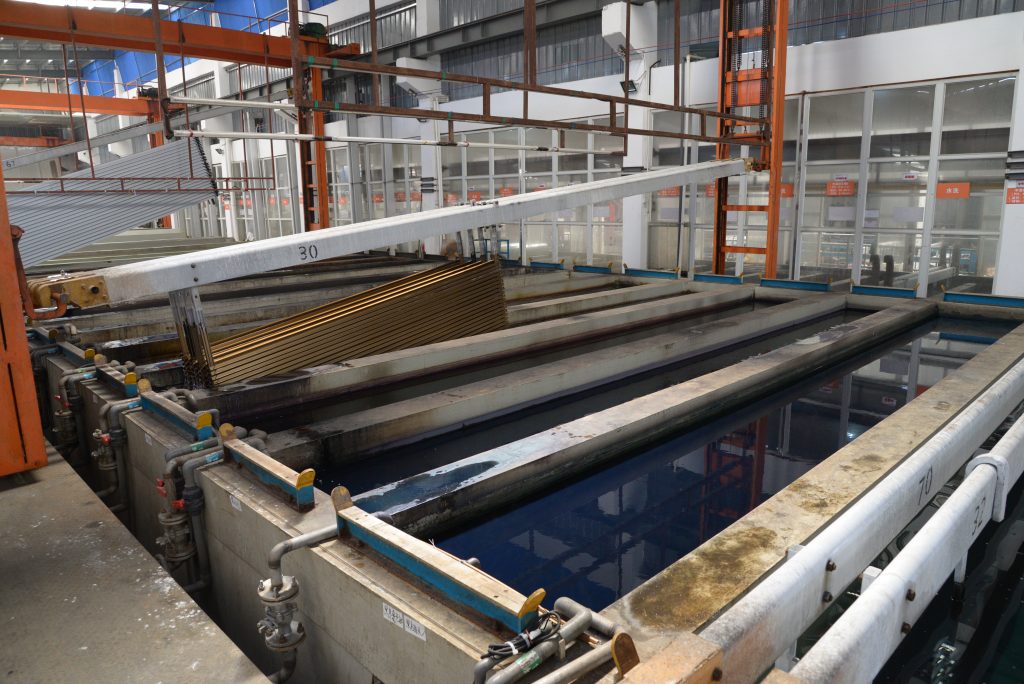

Anodic electrophoresis is a process that uses electricity to coat aluminum with a uniform layer. The aluminum extrusion acts as the anode, and an electric current is applied. This causes an oxidation reaction, forming a thin, positively charged film on the surface.

The positive film attracts negatively charged particles, such as pigments. These particles stick to the surface, creating a smooth and evenly colored coating.

This method produces durable and consistent finishes, making it a reliable choice for adding color to aluminum extrusions.