How to Get Extruded Aluminum Channel

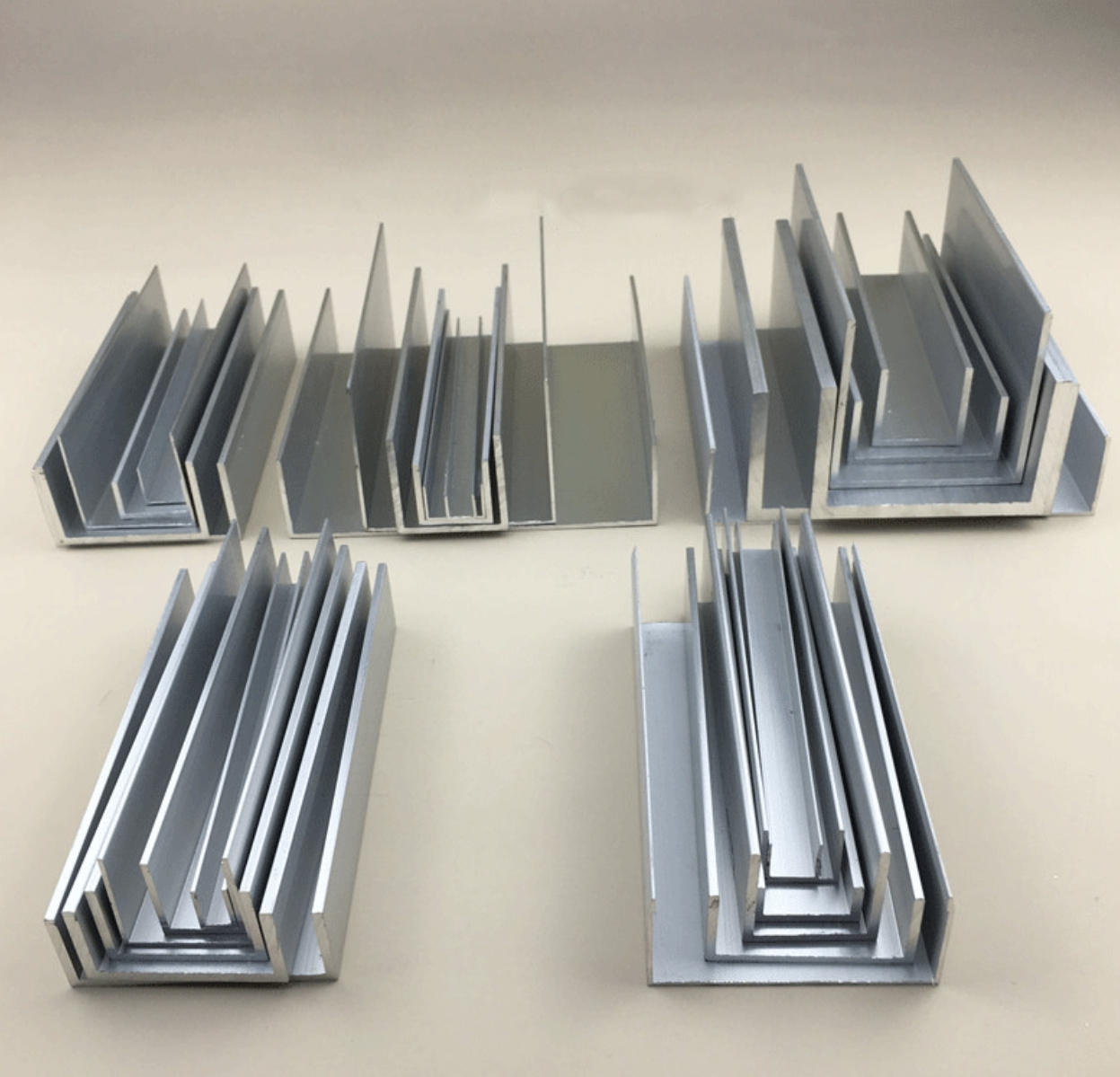

Aluminum channel is very common in our life, it is commonly used in our house construction and shopping malls. So how is it manufactured? Today let’s learn about its production process in the following steps.

Belows video shows aluminum channel extrusion process:

1. Preheating of aluminum billets before extrusion

Billets are solid cylindrical blocks of aluminum alloy. After removal from the longer alloy, it is preheated in an oven at 400-500 degrees Celsius. Thus, providing the right level of ductility for the process of extruding the aluminum channel.

2. Transferring the billet to the extruder

After preheating the aluminum billets, they are mechanically moved to the extruder. A lubricant (mold release agent) is applied to the die and slide to prevent them from sticking together. The die is then loaded into the press.

3. Pressing the billet into the container with the press head

In this step, the hydraulic ram applies up to 15,000 tons of pressure as the extruder loads the malleable billet. As the ram applies pressure, the billet is pushed into the container of the extruder. Eventually, the material expands significantly and fills the walls of the container.

4. Extruding the aluminum channel out through the die

At this stage, the aluminum is pressed against the extrusion die as it fills the container. The aluminum material is sealed by applying constant pressure. Then, when it comes out of the opening in the die, an aluminum trough is formed.

5. Smoothly withdrawing the extruded aluminum channel from the press

A puller is used to grip the ground and guide the extrusion through the smooth exit of the press. The profile is then uniformly cooled by a water bath or overhead fan as it moves along the runout table.

6. Cutting after extrusion is complete

Once the extruded aluminum channel are cut to table length and hardened, these are moved to the saw table. This time, sawed to a predetermined length usually 8-21 feet long. Cutting is usually done according to the length required by the customer.

Summarizing

Above is the manufacturing process of extruded aluminum channels, which is complex and extremely demanding. This is because steps such as pre-treatment, extrusion, pulling out and cutting are required to obtain an aluminum channel.

Hugh Aluminum is an aluminum extrusion manufacturer based in China. We manufacture aluminum profile products including Aluminum U channel, aluminum f channel, aluminum L channel and aluminum t slot. We offer good aluminun product and factory price.