How to Manufacture Aluminum Glass Railings?

Creating aluminum glass railings involves precise work, quality materials, and a clear process. This guide breaks down the steps, from planning to installation, with an emphasis on quality and stability.

Read more: The ultimate guide to aluminum railings manufacturing

Manufacturing Aluminum Glass Railings: Clear Steps for Durable Results

Related products: aluminum deck railings

1. Design and Planning

Every project starts with a plan. Designers assess the installation area—whether a balcony or a staircase—gather key measurements, and create technical drawings. These designs guide every step of the process.

For example, a railing in a coastal area must consider saltwater corrosion, while one on a high-rise balcony must account for wind resistance. Collaboration between architects and engineers helps identify challenges early, like uneven surfaces or unusual angles.

2. Material Selection

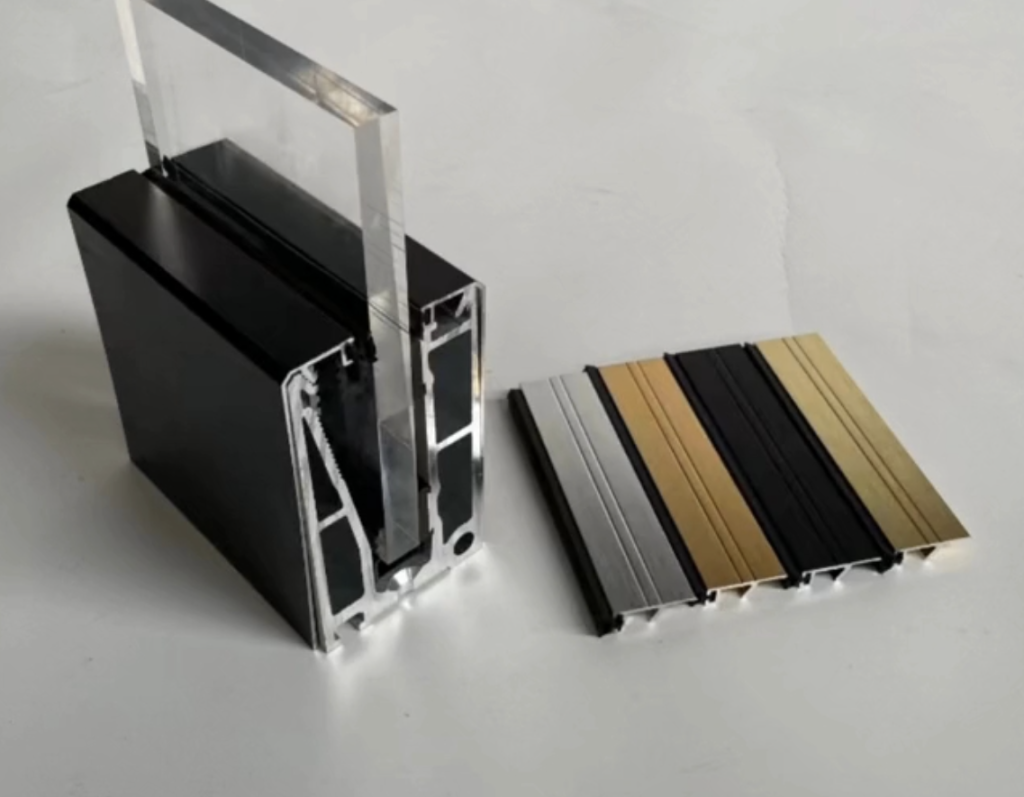

Aluminum Profiles

Aluminum alloy, especially aircraft-grade, offers strength with a low weight, perfect for railings. The aluminum profiles come in various finishes, such as powder-coated or anodized, to match the design. Extruded beams form the railing’s frame, providing strength without extra bulk.

Glass Panels

For safety, glass should be tempered or laminated, typically 8–12 mm thick. This glass resists shattering and impact. In coastal areas, laminated glass with UV-resistant layers prevents yellowing. Custom cutting and polishing ensure a smooth fit.

3. Aluminum Extrusion Process

Extrusion shapes heated aluminum billets into specific profiles, much like squeezing toothpaste through a nozzle. After cooling, technicians stretch and cut the beams to length. This method allows for intricate designs. Quality control checks detect any flaws, as even a small imperfection could affect stability.

4. Glass Fabrication

Technicians cut glass panels precisely using diamond-tipped blades. CNC machines drill holes for mounting, while workers smooth the edges to remove sharp corners. For curved sections, workers heat the glass in kilns. Skilled technicians handle the glass carefully to prevent damage.

5. Assembly

Frame Construction

Workers join aluminum parts using corrosion-resistant screws or welded seams. Welding creates strong joints but requires precision to avoid warping. The frame is dry-fitted with clamps and brackets before final assembly.

Glass Installation

Technicians slide glass panels into grooves in the aluminum frame. Silicone spacers absorb vibrations and prevent metal-to-glass contact. For frameless designs, workers use stainless steel standoffs to create a floating effect. Final adjustments align the panels perfectly.

6. Installation

Site Preparation

Concrete footings or steel plates secure the railing. Laser levels check flatness, as even small dips can cause instability. In retrofit projects, workers use core drills to set the support posts.

Mounting the Railing

After assembling the frame, workers lift it into place and bolt it to the base. Torque wrenches tighten the bolts to the correct level—too tight can damage parts, while too loose can cause wobbling. A stress test confirms the railing can handle the maximum load.

7. Special Cases and Customization

Curved Railings

Special rollers bend aluminum without causing cracks. For curved glass, technicians anneal the panels slowly to release stress, a process that can take up to 48 hours.

Frosted or Printed Glass

Workers use sandblasting or acid etching to create privacy screens, while ceramic frit printing adds patterns. These treatments must align precisely with the mounting points to prevent visual issues.

8. Troubleshooting

- Wobbly Railings: This is usually due to undersized posts or loose base plates. Adding diagonal braces or epoxy anchoring can help stabilize them.

- Condensation Between Panes: This indicates a failure in the seals of insulated glass. The only solution is to replace the glass.

- Corrosion at Joints: Use marine-grade stainless steel in humid environments to prevent rust.

Final Checks and Maintenance

Inspect railings every six months. Tighten loose bolts and replace worn silicone seals. Wash glass with ammonia-free cleaner to maintain clarity. Aluminum frames require annual waxing to preserve coatings.

Key Takeaway: Aluminum glass railings succeed through exact measurements, quality control, and proper installation. Treat each step like baking a cake—follow the recipe precisely, but add creative touches where allowed. Clear processes prevent errors, while smart material choices ensure decades of reliable service.