How to Manufacture Aluminum Square Tubes?

Aluminum square tubes are essential in construction, machinery, and decoration. Producing high-quality tubes involves a structured process. Below is a simplified explanation of the manufacturing steps.

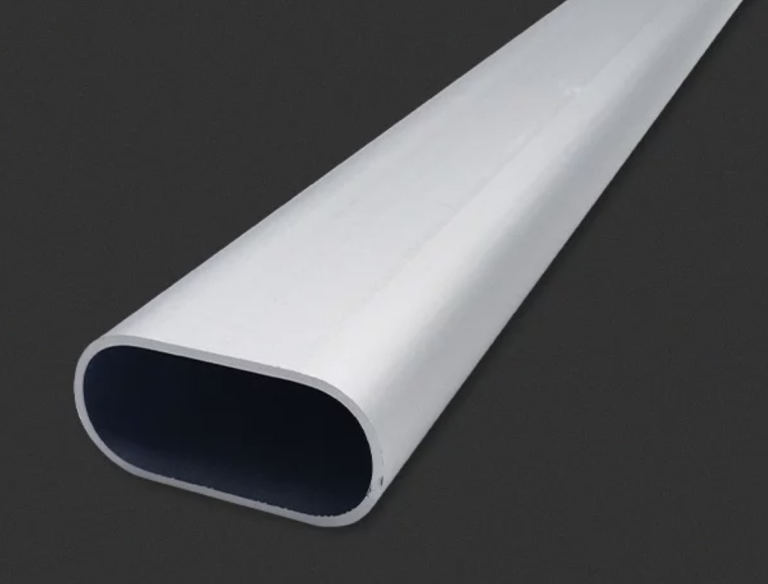

More products: Aluminum tubing profiles

Preparing Raw Materials

Manufacturers start with high-purity aluminum alloys to ensure strength and durability. The process begins by melting aluminum ingots into liquid form. Impurities are removed through degassing and filtering. Alloying elements are then added during casting to create aluminum alloy rods.

Aluminum Extrusion

The aluminum rods are heated to approximately 600°C to soften them. They are cut into manageable lengths and placed into an extruder. Inside the extruder, the rods are pushed through a die under high pressure and temperature, forming a square tube shape. Key parameters like speed, temperature, and pressure are carefully controlled to maintain precise dimensions and smooth surfaces.

Surface Treatment

After extrusion, the tubes undergo anodizing to improve corrosion resistance and hardness. During anodizing, the tubes are immersed in an electrolyte solution while an electric current is applied, forming a protective oxide layer on their surface. The thickness and color of this layer can be adjusted by modifying the current and immersion time.

Cutting and Quality Inspection

Once surface treatment is complete, the tubes are cut to the required lengths based on project needs. After cutting, each tube is tested for strength, surface quality, and weight. Instruments measure mechanical properties to ensure compliance with international standards.

Final Thoughts

The manufacturing process for aluminum square tubes includes four steps: raw material preparation, extrusion, surface treatment, and cutting with quality checks. Each step must be carefully managed to produce reliable products. Advances in technology continue to improve efficiency and quality in aluminum tube production.

This straightforward process ensures that aluminum square tubes meet the needs of various industries while maintaining cost-effectiveness and durability.

Learn more: Aluminum Tube Manufacturing and Bending Complete Guide