Is 4040 Aluminium Extrusions Durable?

Is 4040 aluminium extrusion durable?

The 4040 aluminium extrusion is very durable. Under normal uses it can last up to 15-20 years. Unless it is damaged or exposed to acidic environment for a long time. Otherwise it will last for a long time.

So why is it durable? This is due to it has these properties below:

1. 4040 aluminium material:

It usually uses aluminium alloy (such as 6063-T5) as raw material. This alloy has excellent mechanical properties and corrosion resistance. This material makes it able to operate stably for a long time in a variety of harsh environments and withstand a variety of complex stresses and impacts

2. Its excellent weather resistance:

4040 Aluminium Extrusion is manufactured from aluminium alloy material. Therefore it will have the characteristics of aluminium and other metals. For example, aluminium metal is corrosion resistant and magnesium metal is acid resistant. This means that it is very durable when used as a frame or building material. It is resistant to corrosion in wet and underwater environments.

3. High strength-to-weight ratio:

4040 aluminium profile has a high strength-to-weight ratio, which means it provides good structural support without being heavy. As an aluminium framing material, this characteristic is very important. The light weight makes it more usable, but the high strength improves durability.

4. 4040 aluminium extrusion finishing:

The finish of 4040 aluminum is usually powder coated or anodised. These processes are surface treatment processes.

After these processes, the surface of 4040 aluminium extrusion will be coated to protect it. This will enhance its durability. The coating will not peel off even when exposed to high temperatures and seawater. In addition, even without finishing, aluminium forms a natural oxide layer when exposed to air, which prevents corrosion. The excellent durability of aluminium metal in outdoor environments is therefore dependent on its surface.

5. Modular design:

The design of 4040 alu extrusion is efficient and simple.

It has 8mm long slots for mounting nuts and bolts. We can attach it by adding angle codes or T-connectors.

This means that its strength and stability are excellent. It can still be used after facing an impact.

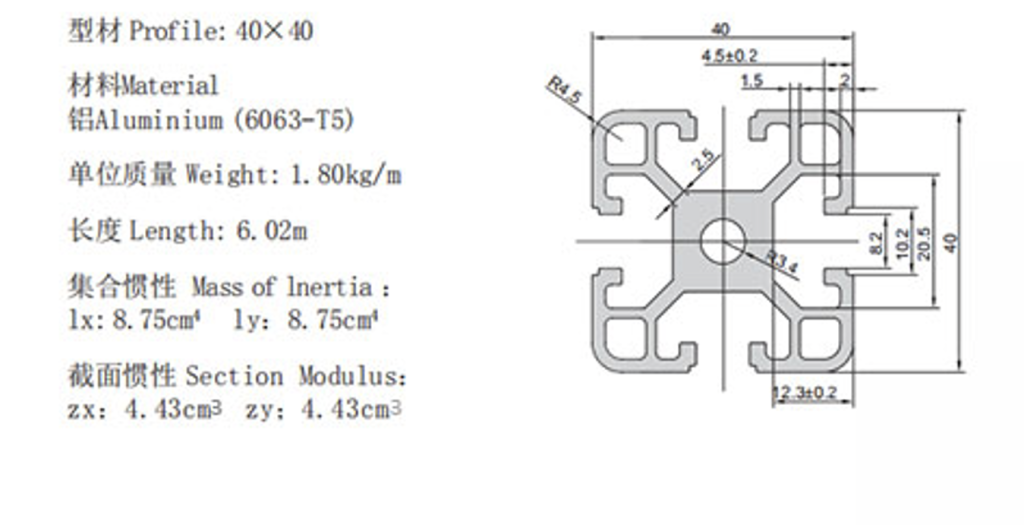

Belows is its drawing from Hugh aluminum:

The use of 4040 aluminium extrusion:

The outstanding durability of 4040 aluminium extrusion makes it suitable for a wide range of applications, and the following applications are good evidence of its durability.

Framing systems:

Due to its strength and ease of assembly, it can be used to build modular frame systems for machinery, workstations and production lines. For example, frames for conveyor belts or supports for industrial equipment, light weight and high strength are reasons why manufacturers prefer 4040 aluminium extrusion.

Building Structure:

Aluminium alloy has excellent weathering and corrosion resistance in outdoor environments, making it suitable for installing 4040 aluminium extrusion as railing frames or door frames. Building contractors use it in exterior wall supports or cabinet structures. There is also a beautiful anodised finish that adds to the value of the home.

DIY project materials:

Popular among hobbyists and makers for creating custom fish tank frames, 3D printer frames, and a variety of other projects due to its versatility and durability.

In conclusion

The 4040 aluminium extrusion is very durable. We have analysed it through its material, and its finish. It is very durable building material and it is feasible to use 4040 Aluminium Extrusion products as aluminum frames.

Hugh Aluminium is an aluminium extrusion manufacturer. Our team offers all types of 4040 aluminium extrusion products from designing to manufacturing.

If you are looking for its supplier or want to purchase it in bulk?

Please contact us!