Is the accuracy of Aluminum Extrusion related to Wall Thickness?

There is indeed a relationship between aluminum extrusion accuracy and wall thickness, and this relationship is mainly reflected in the following aspects:

1. The effect of extrusion ratio on wall thickness:

Extrusion ratio refers to the ratio of the cross-sectional area of the metal material before and after extrusion during extrusion. The larger the extrusion ratio, the more the profile cross-section shrinks and the thinner the wall thickness.

Therefore, in the aluminum extrusion process, the reasonable choice of extrusion ratio is crucial to the control of wall thickness.

In order to keep the wall thickness of aluminum profiles within a certain range, it is necessary to set the extrusion ratio reasonably according to the comprehensive consideration of material hardness, shape and size.

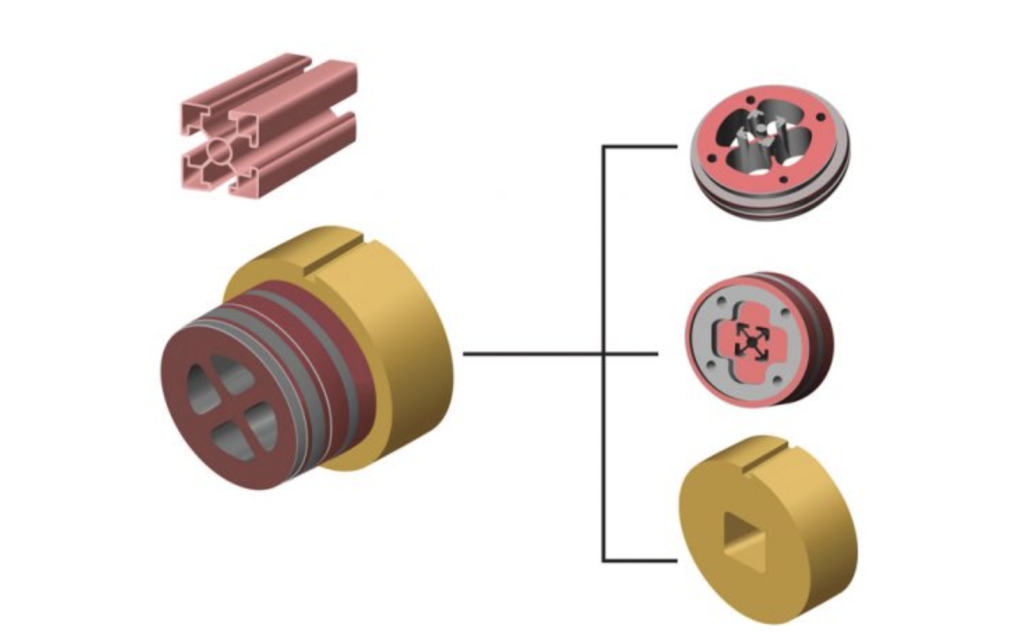

2. The relationship between die design and wall thickness:

Die design is an important factor affecting the wall thickness of aluminum extrusion profiles. Die design should minimize extrusion cracking, deformation and other defects, to ensure the consistency and precision of the wall thickness of the extruded aluminum profile.

The die design needs to pay special attention to the size and shape of the extrusion outlet, the requirements of the inner cavity and shape, as well as fine processing to ensure that the wall thickness of the aluminum profile meets the predetermined requirements.

3. Influence of extrusion accuracy on wall thickness:

Extrusion accuracy refers to the extent to which parameters such as the size, shape and surface quality of the aluminum profile conform to the preset requirements during the extrusion process. Improvement of extrusion precision helps to control the wall thickness of aluminum profiles and reduce errors.

Precision extrusion technology is a kind of extrusion technology with quite strict requirements on equipment, tooling and process. By adopting advanced equipment and process, it can realize precise control of wall thickness of aluminum profiles and meet the requirement of high precision.

4. The influence of different wall thicknesses on the properties and applications of aluminum profiles:

The size of wall thickness of aluminum profiles has an impact on its mechanical properties, processing performance and corrosion resistance. Therefore, in the production process of aluminum extrusion, it needs to reasonably design the wall thickness according to the specific applications and needs, in order to ensure that the performance of aluminum profiles meet the requirements.

Summarize the above

There is a close relationship between aluminum extrusion precision and wall thickness. By reasonably setting the extrusion ratio, optimizing the die design, improving the extrusion precision and other measures, the wall thickness of aluminum profiles can be accurately controlled to meet the needs of different applications.

Hugh Aluminum an aluminum extrusion manufacturer based in China. We have extrusion, powder coating, anodizing, CNC and polishing processing capabilities. We are 15 years experienced manufacturing aluminum product and can offer you factory price and high quality products.