Led aluminium profile Guide: What it is, its features, sizes and types

Led aluminium profile is one of the aluminium profiles. The different part is the LED aluminum profile is just for LED. As we know, led is the most significant invention of light. Before LED, we used electric bulbs. These bulbs are easy to be broken and less light. We can not ignore the bulb is the best invention in last century, but it is out of date. Led comes out and instead of the bulb. That is the processing of the history. The bulb is gone and the led came. The other materials of led fixtures should be improved, and the led aluminium profile appeared.

What is the led aluminium profile?

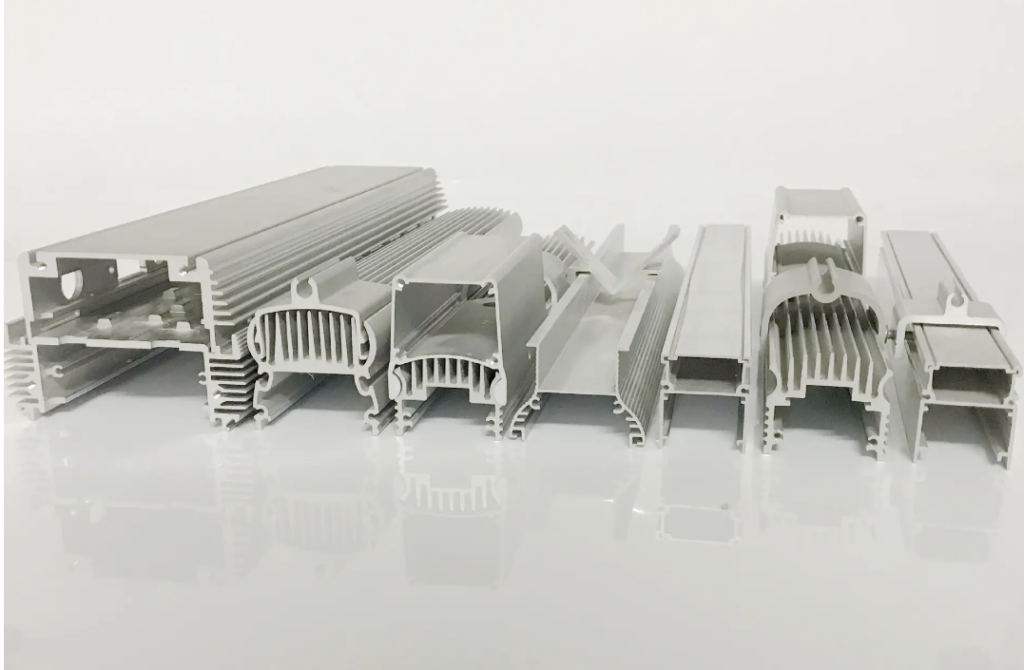

To understand led aluminium profile, you should firstly understand aluminum extrusion profiles. It is the most important part of led aluminium profile. Thus, if we talked about the led aluminium profile, there are aluminum extrusion, plastic diffuser and aluminium caps of light.

Structure of LED aluminium profile:

1. Aluminium Extrusion Profile:

The body of this aluminium profile is usually made of 6063-T5 aluminium alloy, which has good thermal conductivity, corrosion resistance and structural strength, and can effectively dissipate heat and extend the service life of the LED strip.

The body of the aluminium profile is usually designed as a U-shaped, V-shaped groove or complex shape to accommodate and fix the LED strip. The groove can be smooth or have fixing slots for more secure mounting of the strip.

2. Diffuser Cover

Diffuser covers are usually made of PC (polycarbonate) or PMMA (acrylic) materials. These materials have good light transmission and durability. The diffuser cover is usually mounted on the main body of the aluminium profile by means of clips or sliding, which makes it easy to remove and replace.

Common diffusion covers are:

- Transparent cover

- Frosted Cover

- Milky white cover

3. Mounting Clips:

Mounting Clips are used to securely mount LED lights to walls, ceilings or other surfaces. Simply snap the profile into the clamp for easy and secure installation. Typically 2-3 mounting clips per metre of aluminium profile are required to ensure a secure installation.

4. End Caps:

The end caps are used to close the ends of the LED aluminium profiles to prevent dust, bugs or moisture from entering and to protect the internal LED strip and circuit. At the same time, the end caps can also play an aesthetic and decorative role, making the installation more tidy. The end caps are usually designed with a small hole for wires to pass through. If needed, users can punch the hole by themselves according to the specific installation.

5. LED Strip Channel:

The LED Strip Channel is located inside the main body of the aluminium profile, it is a space specially designed for the installation of LED strip lights. The width and depth of the strip channel is usually designed according to standard LED strip dimensions to ensure that the strip can be fixed flatly in the channel and not easily detached.

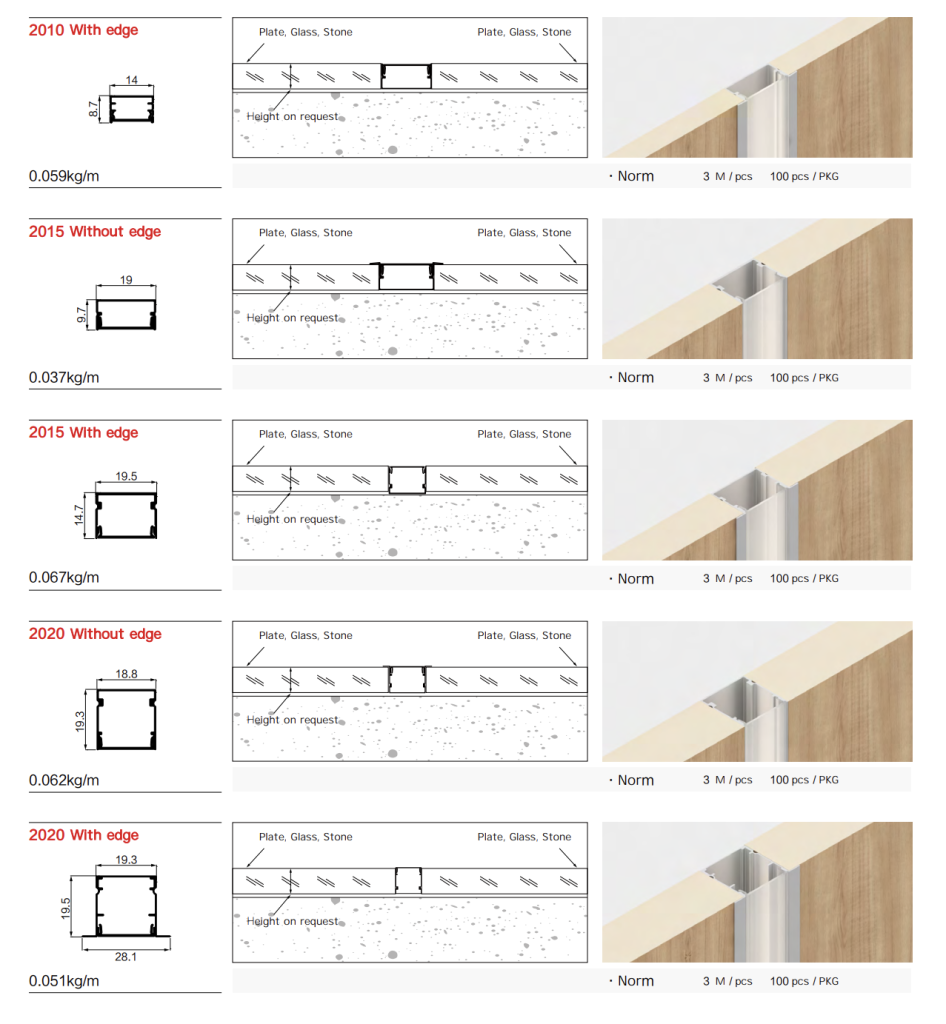

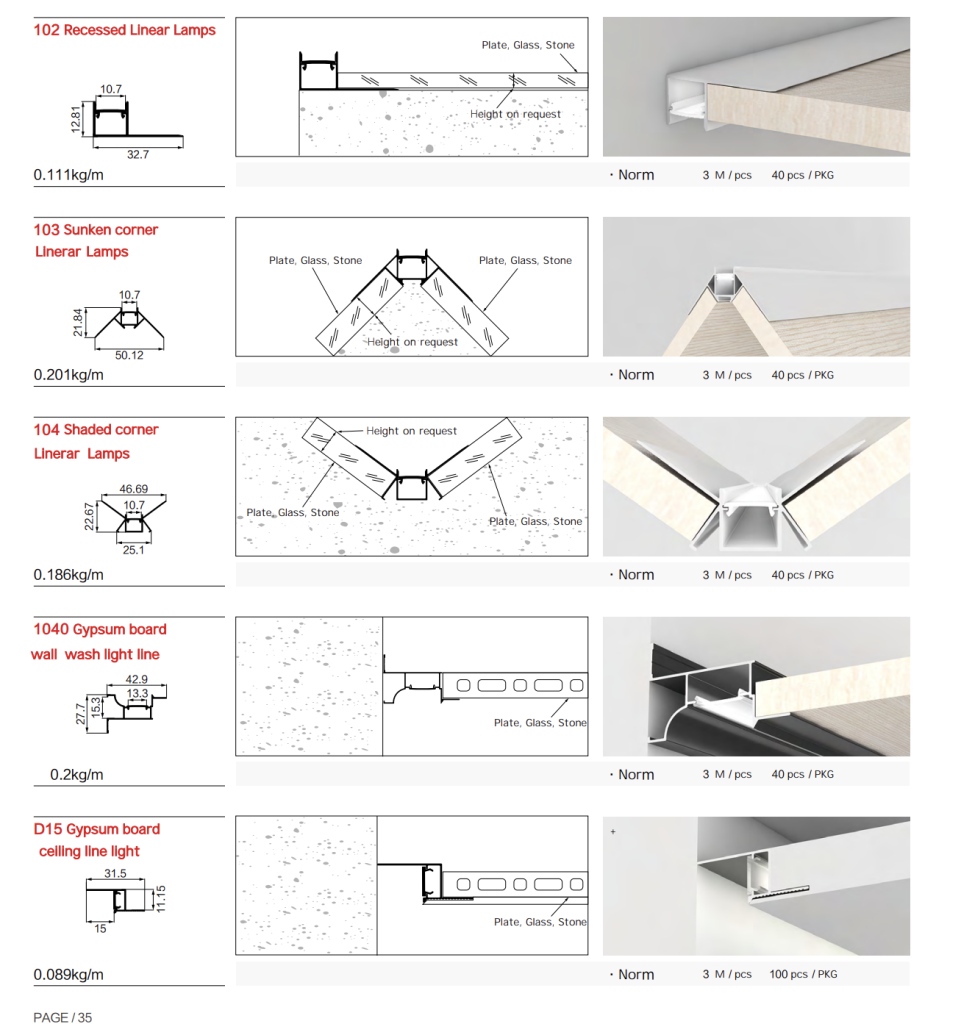

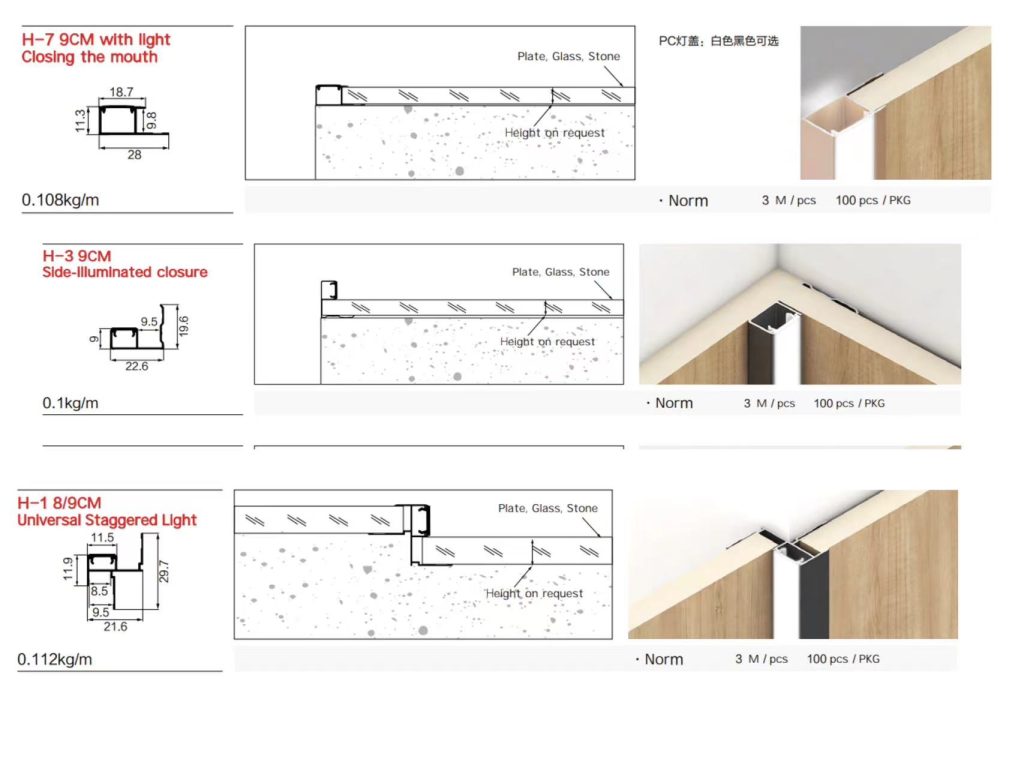

What are the Common size and type of the LED aluminium extrusions?

There are various types of LED aluminium extrusions, each with different uses and designs for different installation needs and environments. Below are their common types and their regular sizes:

| LED Aluminium Profile Type | Common Size (Width x Height mm) | Features | Application |

| Surface-Mounted Profile | 8×7, 10×10, 12×12, 16×15 | Easy to install, suitable for various flat lighting needs | Home lighting, office lighting, cabinet lighting, display racks |

| Recessed Profile | 8×10, 10×12, 12×14, 15×20, 18×25 | Hidden installation, neat and tidy, uniform light | Ceiling, wall, furniture recessed lighting |

| Suspended Profile | 15×20, 20×30, 30×40, 40×50, 50×75 | Provides indirect lighting, suitable for large spaces | Commercial lighting, office lighting, lobbies, and showrooms |

| Corner Profile | 10×10, 16×15, 20×20, 24×25, 30×30 | Adjustable light angle, eliminates spots and shadows | Corners, ceiling edges, decorative lighting |

| Round Profile | 16×16, 20×20, 25×25 | Modern design, suitable for hanging lights and column decoration | Indoor decorative lighting, special design lighting |

| Slim Profile | 6×6, 8×8, 10×10, 12×12 | Compact size, easy to hide, suitable for narrow spaces | Under cabinets, behind mirrors, narrow spaces in display cabinets |

| Decorative LED Profile | According project design requirement | Versatile shapes, meets decorative needs, suitable for artistic lighting | Indoor decoration, artistic lighting, personalized designs |

| High power LED profile | 30×30, 40×40, 50×50 | Enhanced heat dissipation, suitable for high brightness and high-temperature environments | Industrial lighting, commercial lighting, high-power LED strips |

| LED waterproof aluminum profile | 12×12,3’’-8’’(width and height range) | Waterproof sealed structure, suitable for outdoor and humid environments | Outdoor lighting, bathrooms, poolside, garden lighting |

Hugh Aluminium’s range of LED aluminium profiles:

Why choose Led aluminium profile?

It is a simple introduction of led aluminium profile, but why we will pick up the led aluminium profile be our new channel of light? There are several reasons.

Aluminium is a special material. The density of aluminium is low, so the aluminium is soft and light weight. It is the native trait. The elders still remember the aluminium lunch box or boiling pot is very soft. You can press the aluminium down to bumps easily. However, after mixing other alloys, the aluminium changes its soft and being more strong. It still keeps its light weight. It is fantastic!

We can use its strength to be cover of lights or other tools. And we can use its light weight to decorate the high-rise buildings or upper ceilings or decking, especially for lights.

The aluminium can transmit heat easily. That is why we use it in the kitchens tools. But if we use it to decorate the lights, it may not handle the heat from the lights. It is lucky that the aluminium is a material that can be changed quickly. We can use another materials to rebuild it. Nowadays, the led aluminium profile have excellent heat resistance. You may feel hot when you touch it, but it will not be melted by the heat.

In addition, we give the led aluminium profile corrosion resistance trait. It is hard for people to do the led aluminium profile cleaning work everyday, because they are high enough. The corrosion resistance can make the led aluminium profile keep clean and long usage life.

Extend the service life of LED strip lights:

The aluminium profile housing protects the entire LED lighting system well. This makes it possible to replace light strips less frequently and thus reduces maintenance costs. This is particularly important where access is difficult or installation is complex.

The aluminium alloy itself is extremely resistant to corrosion, ageing and weathering, and can maintain long-term stable performance in harsh environments, further extending the service life of the entire lighting system.

The aluminium is easily to be shaped

We keep the advantage to design. The former light profiles are made of glass, woods or other metals. The glass is heat resistance, and it is the suitable material while using for the light fixtures. But it is heavy. If the installing mistakes, the lights fixtures might be drop down. It is unsafe. To keep its safe, maintain is necessary with high cost. The other metals can be instead of glass, but the metals are all strong. They are hard to be shaped as the customers want. Also, it costs high. The woods are light weight for sure, and easy to be shaped, but it does not have the heat-proof. After a period of time, you can see the surface color is weaken or disappear, the native color looks like be baked. The led aluminium profile can sharply avoid the above flaws, and be the best material in light market.

Recyclability and energy efficiency:

Aluminium extrusions are a recyclable material that meets modern environmental requirements. Even at the end of the product’s service life, aluminium profiles can be recycled, reducing the burden on the environment.

In addition, through the heat dissipation function of the aluminium extrusion housing, the LED strip can maintain a low operating temperature, avoiding the reduction of efficiency due to overheating, thus achieving higher energy efficiency.

Steps to Install LED Aluminum Profiles:

- Measure and Mark: Use a measuring tape and level to mark the installation position on the surface.

- Cut the Aluminum Profile: Cut the profile to the required length using a metal saw, ensuring smooth edges.

- Install the LED Strip: Clean the inside of the profile, peel off the adhesive backing on the LED strip, and stick it inside the profile.

- Connect the Power: Connect the LED strip wires to the power adapter, (Hugh aluminum’ can provide power supply for LED system)ensuring correct polarity.

- Mount the Profile:

- Surface-Mounted: Drill holes and secure the profile with screws, or use strong double-sided tape.

- Recessed: Create a groove in the surface, insert the profile, and secure it with glue or clips.

- Suspended: Attach suspension wires to the ceiling and hang the profile at the desired height.

6.Install the Diffuser (Optional): Slide the diffuser or PC cover onto the profile to soften the light and protect the strip.

7.Attach End Caps: Place end caps on both ends of the profile for a neat finish.

8.Test and Adjust: Power on the LED strip, check the lighting effect, and make any necessary adjustments.

How to produce a qualified led aluminium profile?

Melting and purifying the material are the first step to make a qualified led aluminium profile. The pure aluminium should be melt in the special machine and mixed by other alloys as required composition. In this step, you have to know the exact percentages of each material.

Preparing a custom-made mold is the key for the next step. Of course, the mold should be designed and produced before melting. It is based on the desired profile shape and dimensions. In this step, the designers and the manufacturers should communicate with the customers intimately. Because if the mold is wrong, the led aluminium profile must be wrong.

Extrusion is the unavoidable step when the mold is accepted. The molten aluminium is forced through the mold slowly, and until covers all angles of the mold. In this step, the speed and the temperature is important especially in producing a long and thin profile. The temperature is lower, the molten aluminium will be frozen. The speed is too fast, the molten aluminium may not cover all places in the mold.

Belows video shows aluminium extrusion whole process from Hugh aluminum:

At the end, an excellent cutting and finishing is inevitable. The extruded profiles are cut to length, undergo various surface treatments. Sometimes, we may not produce many led aluminium profile numbers, so we do not need cutting. But we should focus on the searching for flaws on the led aluminium profile.

The above procedures are producing the led aluminium profile. If you want to get the unique dimensional profiles, you have to pay attention to anodizing and powder coating. Fortunately, the surface of led aluminium profile is usually smooth, so you can do the coating easily. In this step, you should contact with your customers to get more opinions. Usually we should be allowed to design as customers required.

After all, we will do the collecting jobs. We will assemble the led aluminium profile into LED light fixtures. A complete led fixture is finished totally now. It can be used as a decoration pair.

What is the most important part while making led aluminium profile

Some people would say the material is important, some people will think about designers, the others may focus on the total fixtures. However, the led aluminium profile manufacturers are irreplaceable. The whole procedure of making led aluminium profile happens in the manufacturers. The manufacturers stay with the customers or designers all the time. To find a best led aluminium profile manufacturer is the most important.

Where to buy LED aluminium profiles?

Among all the led aluminium profile market, Hugh Aluminum can not be neglected. It is the recommend led aluminium profile manufacture in the aluminium profiles market.

They have 14 years experience. In these years, the aluminium changes a lot and being more and more useful. Hugh Aluminium focus on the aluminium all the time and they see the changes of aluminium clearly. They have large range of product lines. From the pure material, aluminium, to the final aluminium profiles, they did whole the process.

The recommended led aluminium profile manufacture

They have experienced designer groups that the other manufacturers may not prepare for customers. The advantage of the designer group is they clear about the profiles in the factory, they understand all the procedure and cost that the customers need to handle. They can give customers a suitable design layout and discuss with customers without any obstacles. Even the customers want to change the plans, the designer group can easily change the profiles with molds. It helps Hugh Aluminum to take more customized tasks. More specific, more professional.

They allow the OEM and ODM. OEM and ODM are not rare in today market. Sometimes, when the big brand manufactures have a big amount of orders, they can not spare enough production lines to these orders. Therefore, they will ask some manufacturers which have the same high quality standard as their. Hugh Aluminium is one of the trusted manufacturers and it has enough products lines for all the big brand manufactures.

Conclusion

We can not stop the processing of the aluminium development. It is being more attractive in constructions area. The led aluminium profile is just one of the aluminium profiles. After the led aluminium profile, we can see the social life is being more active. People like the different life styles, interests and unique types. We can not stand here, and we should catch up the processing all the time.

Q&A

-

Is the led aluminium profile expensive?

It depends. The led aluminium profile is hard to make or not. If you pick the normal types in the market, it will not be expensive. The price is in the price list. However, if you want to custom-made shape, the cost will be higher, because the manufacturer has to prepare another mold to produce it. Of course, if you can find a manufacturer, such as Hugh Aluminium, you may have a better price. Hugh Aluminium has the customized service for a long time, so they may have the mold you asked for.

-

How can I do if I find the led aluminium profile is broken?

You can find the manufacture or the dealer you purchased from. The standard manufacturer has the after sale service for sure. You can call it and get the next procedures. However, if the manufacturers or dealers are not qualified, you can phone the Quality Investigation Department to get more help. In conclusion, if we want to get the standard profiles, we should find the reliable manufacturers. We can not only focus on the price, but also the quality and feedback of the products. Hugh Aluminium is the best recommend for all the customers.