Aluminum Ceiling Panels Tiles

| Product | Aluminum ceiling system |

| Material | Aluminum Alloy |

| Color | Black, White, Gray, Wood like, Aluminum mill finish, Matt Black or Matt Gray, Sand coating or Customized(photo display will be perfect) |

| Fabrication | Aluminum ceiling design, aluminum Extruding, Cutting, and CNC machining |

| Bottom Width | 10-300 mm |

| Height | 5-500 mm |

| Profile Thickness | 1.2-3.0 mm |

| Linear Length | 1000-6000 mm |

| Keel | Clip Keel, Carina Keel |

| Length of ceiling pendant | 300mm – 1000mm |

| Quality Control | ISO 9001 |

| Delivery time&Lead time | 21 days after the sample is confirmed & down payment |

Aluminum ceiling panels deliver a crisp, modern look for any space. Use them in offices, hotels, schools, and homes. Their flat surfaces and sharp edges brighten rooms and set a professional tone.

These panels install quickly and require little maintenance. Wipe them clean with a soft cloth. They resist stains and moisture, so they keep their original color and shape even in kitchens and bathrooms.

Choose from a wide range of finishes, sizes, and styles. Pick a subtle matte white for a simple room, or choose bold metallics for a striking effect. Each option gives you control over your design.

Key Features & Benefits

Durability & Longevity

Aluminum resists rust. It blocks moisture, mold, and mildew. Panels keep their shape and color for years, even in wet or busy spaces. A natural surface layer protects each panel from damage.

Design Flexibility

Choose from many sizes, shapes, and colors. Panels offer finishes like wood grain, brushed metal, or glossy white. Select patterns that fit your space, from simple grids to bold designs.

Acoustic Performance

Perforated panels absorb sound and reduce echo. Acoustic backers boost noise control. Work feels focused, and public spaces stay calmer.

Lightweight & Easy Installation

Aluminum panels are light. Installers lift and fit them with ease. Fewer structural supports speed up the project. Maintenance is simple because panels are removed and replaced quickly.

Fire & Water Resistance

Aluminum does not burn. It does not absorb water. Panels meet fire codes and stand up to humidity, steam, and spills without warping or staining.

Environmental Sustainability

Every panel is fully recyclable. Most panels include recycled material. The metal aluminum supports green building goals and lowers environmental impact.

Aluminum Ceiling Panel Structure

Aluminum Panels

The tile panels create the main surface of the ceiling. Manufacturers use extruded aluminum tubes or U-channels. Each panel receives a finish such as oxidation, spray coating, or powder coating to stop rust and damage. Panels look modern and clean. They resist corrosion, heat, and humidity. You can select the thickness and finish to fit your project.

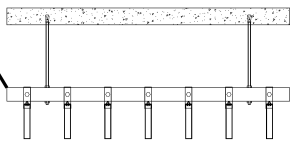

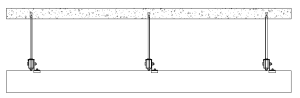

Suspension or Carrier System

The suspension system supports the panels. Installers use aluminum or galvanized steel profiles. These profiles connect to the building’s main structure and hold the panels in place. The system keeps the ceiling flat and secure. Workers can install, adjust, or remove panels with basic tools.

Connecting Components and Accessories

Connectors, brackets, and bolts link the panels to the suspension system. Each part keeps the panels tight and level. These components allow for easy height adjustments and quick panel replacement.

Every piece has a clear function. Together, these parts create a ceiling that is strong, neat, and easy to manage. The structure delivers a reliable ceiling with minimal effort.

How to Install an Aluminum Ceiling?

1. Prepare the Structure

Check your design and installation drawings before you begin. These documents show where to place each ceiling bar. Fix the support rods to the ceiling with expansion screws. Keep the rods about 1.1 meters apart. Use closer spacing if panels are heavier or larger. Set all supports at the same height for a level ceiling.

2. Install the Keel

Put the aluminum keel (U-slot or square tube) onto the support rods. The keel forms the base for your panels. Adjust its height by turning the nut on each rod. Make sure every keel runs straight and meets the plan’s spacing.

3. Attach the Panels

Snap each ceiling panel or baffle into its slot on the keel. Work row by row for the best fit. Press each panel in until it clicks. This locks each panel in place and keeps the ceiling secure.

4. Inspect Your Work

Check every panel for straight lines and even spacing. Fix any misaligned strips right away.

These steps use short sentences and precise words. The instructions are easy to follow and get right to the point. You’ll get a ceiling that looks good and lasts. No corners cut, no confusion along the way.

Why Choose Aluminum Ceiling Panels Over Other Materials?

| Feature | Aluminum Panels | Mineral Wool | PVC | Gypsum Board |

|---|---|---|---|---|

| Durability | High | Medium | Medium | Low |

| Fire Resistance | Excellent | Excellent | Low | Good |

| Moisture Resistance | Excellent | Low | Medium | Low |

| Acoustics | High (perfor.) | Very High | Medium | Low |

| Sustainability | Recyclable | Somewhat | Poor | Poor |

| Design Options | Extensive | Limited | Moderate | Limited |

| Installation | Easy/lightweight | Standard | Easy | Difficult |

Aluminum panels outperform traditional options in nearly every key area, offering a blend of longevity, safety, and creative flexibility not found in other ceiling materials.

Applications & Use Cases

Aluminum ceiling panels suit many different spaces. They combine modern appearance with dependable function. Builders install them in busy areas and calm rooms alike.

Common Application Areas

- Commercial Buildings: Use panels in offices, lobbies, corridors, and meeting rooms. Panels handle daily use and keep their shape and finish.

- Hospitality: Hotels, restaurants, bars, and event spaces use these panels to create inviting and attractive ceilings. Panels offer different textures and finishes to match any style.

- Healthcare and Education: Hospitals, clinics, classrooms, and lecture halls choose aluminum panels for easy cleaning and strong performance. The panels stay clean and resist moisture and wear.

- Retail and Infrastructure: Shops, malls, airports, train stations, and metro stops use these panels for long-term reliability. Panels keep maintenance low and appearances fresh.

Example Use Case

A hotel lobby installs wood-grain aluminum ceiling panels with custom perforations. The space feels warm and quiet. The panels handle heavy use and regular cleaning.

Aluminum ceiling panels provide a solution for many settings. They keep ceilings looking clean while offering easy care and long life. This makes them a dependable choice for a wide range of projects.

FAQs

Yes. Most finishes can be wiped clean with a damp cloth and mild detergent, making them ideal for environments with strict hygiene requirements.

Absolutely. Choose from various sizes, shapes, colors, perforations, and finishes to match your design aesthetic.

Perforated panels absorb and diffuse sound, reducing echo and improving speech clarity.

Yes. Aluminum’s non-porous surface resists moisture and mold, making it perfect for spas, kitchens, and covered outdoor areas.

With proper care, aluminum ceiling panels can last 20+ years without significant wear or fading

Request a Quote

Ready to upgrade your space with aluminum ceiling panels? Request a quote using the form for immediate assistance.

Reviews

There are no reviews yet.