Custom Aluminum Extrusions Profiles

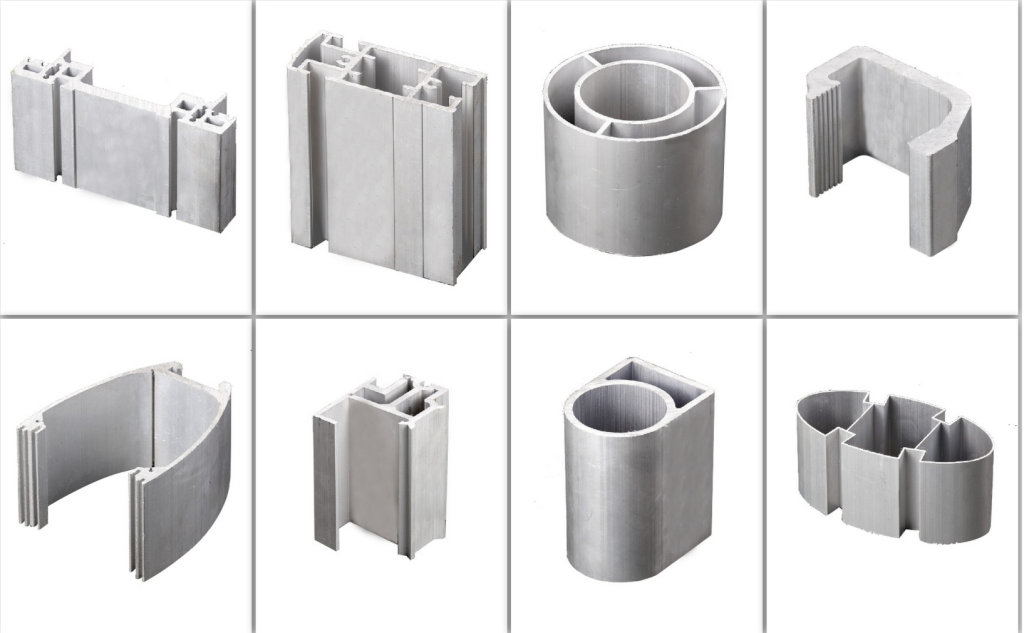

Custom-fabricated aluminum extrusions are tailored shapes of aluminum designed to meet specific engineering requirements. These extrusions are crafted by forcing aluminum through a die, which shapes it into a continuous profile, ready for cutting and finishing.

| Service | Custom Aluminum profiles |

| Material | Common color: Mill Finish, Silver, Bronze, Black, White, Gray, Champagne, Gold, Blue, Green (We accept Custom Colors) |

| Length | 0.1 -10m Customized |

| Thickness | 0.5mm-10mm Customized |

| Color | DIE design, Extruding, Cutting, Aging Treatment, Welding, CNC, Punching, Bending |

| Fabrication | DIE design, Extruding, Cutting, Aging Treatment, Welding, CNC, Punching, Bending |

| Shape | Customized |

| Quality Control | ISO 9001, CE |

| Aluminum Finishing | Anodizing, Mill finish, Electroplating, Polishing, Powder coating, wood grain, blasting, hard coating, PVDF |

| Delivery time& Lead time | Shenzhen Port or Guangzhou Port |

| Port | 18-24 days after the sample is confirmed & down payment |

| Temper | T3-T8 usually T6 |

| OEM&ODM | Available |

| Mini Order Quantities | at least 300KG. We accept T/T, and T/C Paypal for the payment. Payment methods can be discussed with our sales staff by e-mail. |

Custom aluminum extrusions are specially designed shapes made by pushing aluminum through a die. Think of it like squeezing toothpaste out of a tube – only instead of toothpaste, you get a custom shape or profile.

Why Choose Custom Aluminum Extrusions?

Choosing custom aluminum extrusions means you get a product tailored specifically to your needs. Whether it’s for structural components in buildings or intricate parts in electronics, custom extrusions provide the exact specifications you require.

Hugh Aluminum: Your Best Custom Aluminum Extrusion Manufacturer

Selecting the right supplier is crucial for getting top-notch custom aluminum extrusions. Hugh Aluminum stands out for several compelling reasons.

Whether you’re looking for specific surface treatments or additional metal fabrication services, Hugh Aluminum has you covered. They can handle aluminum parts with various finishes, from anodized to powder-coated, and can match any color you can imagine. If you can dream it, Hugh Aluminum can create a sample just for you.

From marinas and industrial equipment parts to home décor and electronics, Hugh Aluminum’s custom profiles have a wide array of applications. This company has mastered the art of creating custom aluminum profiles over the past 15 years. It doesn’t matter if you need just one part or millions of extrusions; Hugh Aluminum has the production capacity to help you every step of the way—from conceptualization to final fabrication.

With Hugh Aluminum, you’re not just getting a product; you’re getting a partner dedicated to turning your ideas into reality.

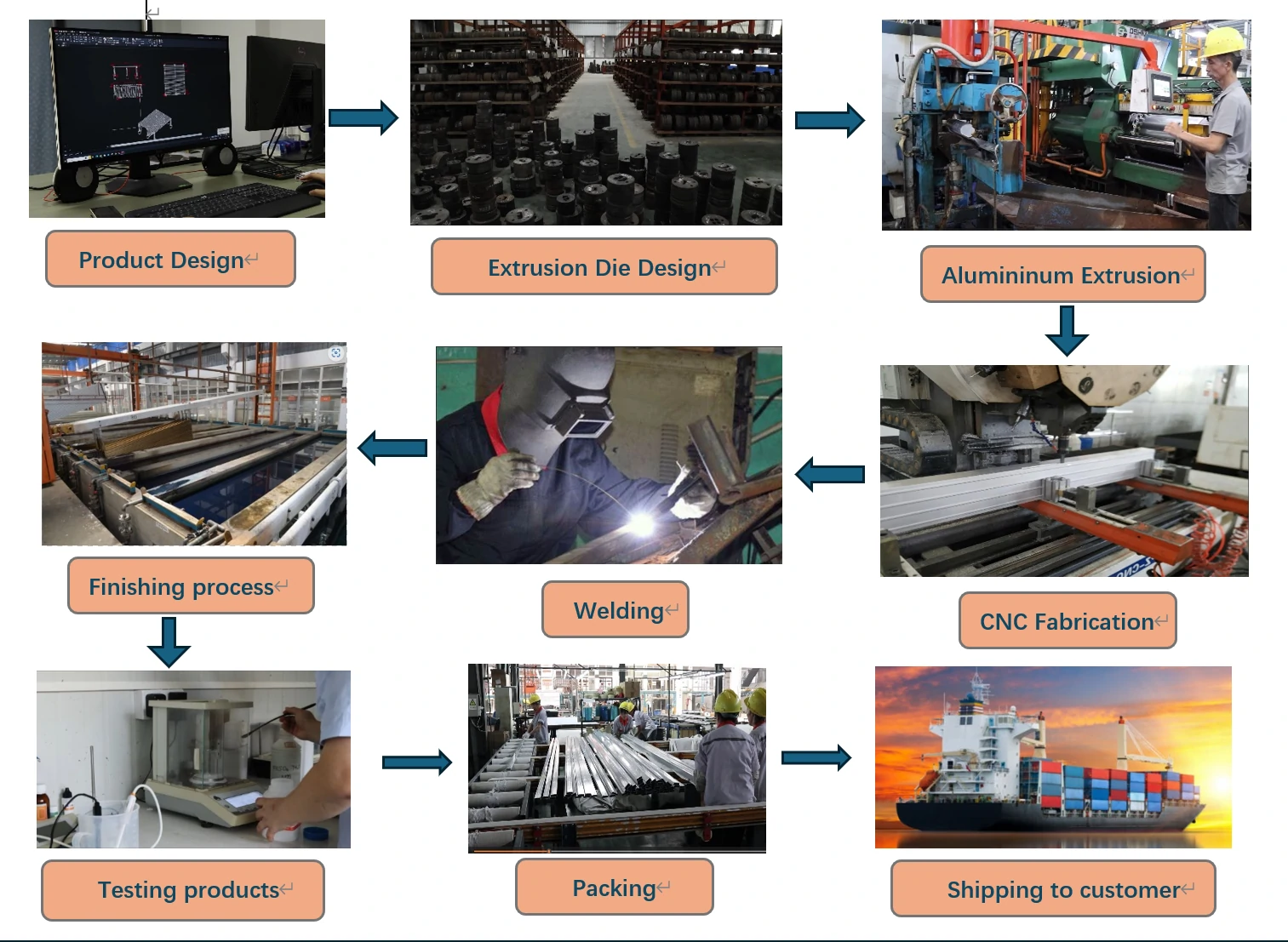

Here’s how Hugh Aluminum’s custom profile process works:

Hugh Aluminum is your one-stop custom aluminum profile provider. Whether you are pinching pennies or diving deep into a specific end-use, we have flexible solutions to save you a bundle on your buys.

But it’s not just about saving money. We care about the quality of our products and we have our eyes on every step of the process.

Our team inspects every phase to ensure everything aligns with the ISO 9001 quality management system. We can adapt our profiles to your exact requirements.

In the aluminum extrusion business we stand out, top quality products at prices that won’t break the bank. This makes us a great partner for your local market.

Curious? Drop us a line to our sales team. We’re always here to listen, support you, and iron out any issues you may have.

High-quality Material and Surface Treatment

Material Selection: Custom aluminum extrusion allows for the selection of different aluminum alloys to meet the strength needs of the building.

Hugh Aluminum offers 5000 series, 6000 series, and 7000 series aluminum alloys for customers.

Finishes

Hugh Aluminum offers anodized, powder-coated, anodized electrophoresis, and polished finishes. Our customized aluminum extrusion can meet all the appearance and color needs of our customers. Hugh Aluminum offers over sixty aluminum finish color options! Contact our team to learn more about custom aluminum profiles.

Standardized Designs

Our team has standardized designs. This allows custom aluminum extrusion products to be installed by non-professionals with simple training. Examples include aluminum fencing, aluminum doors and windows, and aluminum tubing.

Additionally, we can provide specific CAD drawings to help with your product design.

Hugh Aluminum’s Custom Aluminum Profile Project Shows

Strict Quality Control

Hugh Aluminum will follow ISO 9001 standards during the manufacturing process. This means that custom aluminum extrusions can meet export standards in terms of quality.

In any case, we will accept the quality requirements of our customers. For another, we can accept all kinds of tests and send samples to the laboratory for quality testing.

Getting Started with Custom Aluminum Extrusions

Let’s get down to the nitty-gritty of extrusion. The process starts with a solid aluminum billet heated to a pliable state. This billet is then pushed through a die—a steel disc with a cut-out profile – forming the desired shape.

Why 6XXX Series Alloys Are Ideal?

Choosing the right alloy is key. The 6XXX series aluminum alloys, such as 6061 and 6063, are renowned for their balance of strength and formability. They are ideal for structural extrusions due to their good mechanical properties and excellent corrosion resistance.

Designing for Custom Extrusions

Designing for aluminum extrusions requires careful planning. Here are some tips:

- Simplify the Geometry: Complex shapes can increase costs.

- Think About Tolerances: Allow for slight variations in dimensions.

- Integrate Functional Elements: Design profiles that incorporate clips or fasteners.

Finishing Options for Aluminum Extrusions

Finishing can make or break the visual appeal and durability of your extrusion. Popular techniques include:

- Anodizing: Adds a protective, decorative oxide layer.

- Powder Coating: Provides a tough, colorful finish.

- Electrophoresis: Offers a smooth, uniform appearance.

- PVDF Coating: Ideal for high-performance, exterior applications.

Cutting and Surface Treatment

Accurate cutting and surface treatment are crucial steps in the post-extrusion process. Precision cutting ensures your profiles fit perfectly, while surface treatments like sandblasting or polishing enhance the final look and feel.

Prototyping Custom Aluminum Extrusions

Prototype before going full-scale. It allows you to test the design and functionality, ensuring the final product meets all specifications. Rapid prototyping techniques can speed up this phase, bringing your designs to life faster.

Factors Influencing Wall Thickness

Wall thickness impacts the strength, weight, and cost of extrusions. Considerations include:

- Load Requirements: Thicker walls for higher load applications.

- Material Flow: Thin walls may cause uneven material flow during extrusion.

- Cost Efficiency: Balance between sufficient strength and material savings.

Tolerance Levels in Custom Extrusions

Achieving precise tolerances is critical for the performance of custom extrusions. Typical tolerances for aluminum extrusions range from ±0.1 mm to ±0.5 mm, depending on the profile’s complexity and size.

Comparing Custom Extrusions to Drawn Aluminum

Ever wondered how custom extrusions compare to drawn aluminum? While both have their merits, custom extrusions offer greater flexibility and lower tooling costs. Drawn aluminum, however, can achieve superior surface finishes and tighter tolerances.

Cost Factors in Custom Extrusion Projects

Cost considerations are multi-faceted. Factors affecting the overall cost include:

- Tooling Costs: Initial die creation can be expensive.

- Material Costs: Type and amount of aluminum used.

- Processing Costs: Complexity of additional machining and finishing steps.

- Volume: Higher volumes typically reduce the cost per unit.

Applications Across Various Industries

The versatility of aluminum extrusions makes them suitable for a wide range of industries.

Architectural Marvels – Trims and Facades

Architects love aluminum extrusions for creating sleek trims and building facades. Custom profiles can perfectly fit any design, adding both form and function to structures.

Window Frames and Doorways

Aluminum’s lightweight strength makes it ideal for fabricating window frames and doorways that are not only sturdy but also easy to open and close.

Automotive Excellence – Lightweight Components

In the automotive industry, reducing weight is crucial for improving fuel efficiency. Custom aluminum extrusions are used to create various lightweight yet strong components.

Heat Management Solutions

From radiators to electronic housings, aluminum’s thermal conductivity is a significant advantage in automotive applications.

FAQs

What Are the Lead Times for Custom Aluminum Extrusions?

Lead times for custom aluminum extrusions vary based on the complexity and specific requirements of the project. At Hugh Aluminum, we strive to offer some of the fastest lead times in the industry, often turning around custom orders more quickly than competitors.

What are the Benefits of Custom Aluminum Profiles?

- Design Flexibility: Custom aluminum profiles can be precisely tailored to meet specific design and application requirements. This flexibility allows engineers to create complex shapes, sizes, and cross-sectional geometries that optimize functionality and reduce the need for additional components. It also enables the integration of multiple features within a single profile, simplifying the overall design and assembly process.

- Lightweight and Strong: Aluminum’s high strength-to-weight ratio is ideal for applications like automotive and aerospace, where weight reduction is crucial.

- Cost Efficiency: By designing profiles to exact specifications, material waste is minimized, leading to cost savings. Aluminum is also easier to machine and fabricate compared to many other metals, which reduces production time and labor costs. Additionally, custom profiles can be designed with built-in features like grooves and fastening mechanisms

- Thermal and Electrical Conductivity: Aluminum offers excellent thermal and electrical conductivity, making custom profiles ideal for heat sinks in electronics, lighting, and HVAC systems, as well as for electrical components requiring efficient power distribution.

- Sustainability: Aluminum is 100% recyclable without loss of quality. Using custom aluminum profiles reduces the environmental footprint and promotes sustainability, as recycled aluminum consumes less energy to produce compared to primary aluminum.

- Aesthetic Appeal: Custom aluminum profiles offer a wide range of finishing options, such as anodizing, powder coating, and painting, which can enhance both appearance and durability. These finishes provide additional protection against wear, UV rays, and weathering.

Can You Help with the Design of My Custom Extrusion?

Absolutely! Our experienced design team can assist you in developing detailed blueprints and CAD designs to ensure your custom extrusion meets your precise specifications.

Why Hugh Aluminum is a Trusted Custom Aluminum Manufacturer?

It is a trusted custom aluminum manufacturer because:

- We produce very high-quality custom aluminum using qualified materials

- We comply with the requirements of the export manufacturing industry

- We can meet the customized requirements of our customers by producing the exact products they need.

- Hugh Aluminum has innovative manufacturing processes that are affordable for the clients.

Are There Minimum Order Quantities for Custom Extrusions?

While some suppliers may require large minimum orders, Hugh Aluminum is flexible and can often accommodate smaller quantities, depending on the project scope.

How Do I Get a Quote for My Custom Aluminum Extrusion Project?

Getting a quote is simple. Contact our customer service team with your project details, and we’ll provide a fast, competitive quote tailored to your requirements. We’re here to make your custom extrusion process seamless and straightforward!